|

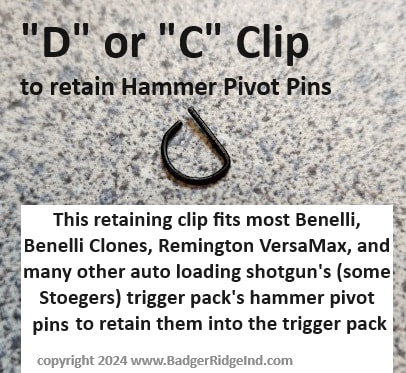

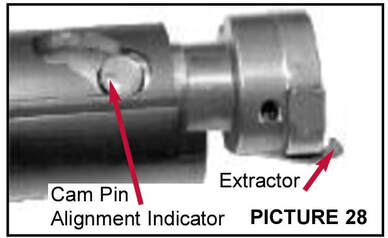

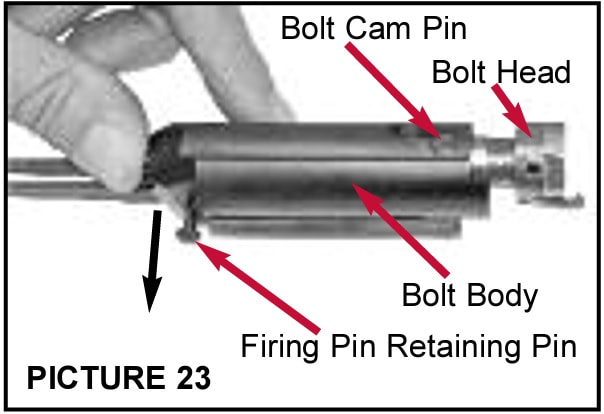

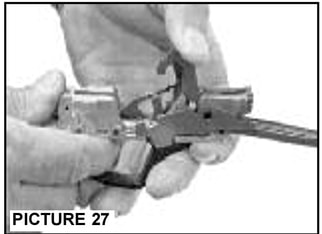

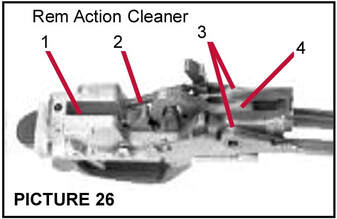

Thanks for visiting the The Badger's Den (the blog for Badger Ridge). If an internet search brought you here looking for muzzleloader solutions, please stick with us: we have the solution to your Remington 700 ML/MLS and Ruger 77/50 woes. I update this blog frequently and what you are looking for is probably one or two clicks away. This blog is sorted categorically and chronologically. So you can find what you want by looking in the appropriate category, or if you know when it was published, you can use the time line. Or just keep scrolling down! If you are new to our site: YES WE STILL SERVICE AND CONVERT THESE OLD MUZZLE LOADERS But for this installment I'd like to tell you about a new product service we offer: Remington VersaMax Cam Pin, Hammer, Spring, & Plunger Replacement Parts I purchased a VersaMax about 7 years ago and have been very happy hunting waterfowl with it. Its a bit on the heavy side to carry all day upland hunting, but its been my "go-to" gun for waterfowl. It recoils softly. It smoothly cycled everything from the lightest trap/skeet loads, to the heavy 3.5" magnum waterfowl loads with out a hitch (well almost... there was one time I wore a supper fluffy warm glove on my left hand that jammed up the loading port... but that was hardly the gun's fault). I bought mine due to the reviews I read, and was really exited to own a US made "Benelli clone." I couldn't ever come to believe I could afford a Benelli, and being able to own one made in the USA.... with an improved gas system was a great thing to me. If you didn't know: the VersaMax is a clone of a Benelli M4 (the only autoloading shotgun to pass US military trials) adopted by the USMC as the M1014. After USMC adoption I understand Remington cloned it secretly, improved the Benelli Argo gas system (and called that the VersaPort system) and then waited. They waited for the day the Benelli M4's patents expired to patent their improvement as the VersaMax and began selling it. Unlike the M4/M1014 Remington gave the Versa Max a standard sporting shotgun stock and barrel, and a few other changes. And I flat out love it. I've shot some of my best trap ever with it, and I've killed a lot of waterfowl with it too. And did I mention it's super soft recoil and reliable with every factory load I've fed it? I've also installed an extended magazine system on my VersaMax. I switch back and forth between the stock system and the extended system when I go on snow goose hunts. I really love my VersaMax. Well... I must say it 'cycled' perfectly (past tense) until one snow goose hunt I started getting lots of soft primer strikes. The gun would still cycle smoothly (feed and eject), but frequently when I swung on a goose, and hit the trigger I'd get a 'click'. I'd cycle a new shell in, and most of the time it would go off. Typically the first shell would go off, but the second one would not. Some times it didn't matter if it was the first or one of the subsequent shots. I looked at the shells that didn't fire and saw a slight primer indent. When I put the same shell in my back up gun, it went bang. These soft primer strikes occurred after I'd put over 1000 rounds through my VersaMax (probably closer to 1500, as I wasn't counting I can't be sure). So I hunted my back up gun to finish the day, and that evening cleaned the VersaMax. I didn't really find it too dirty to function. Especially considering how dirty I'd gotten the same gun before (and it had never had a hiccup with about 300-400 rounds per deep clean). Notably, my friend on the same hunt swung a VersaMax and he had the same issue start on the same day of the same hunt. His gun was pretty clean when we disassembled it as well. We both use lubes that deal well with the cold, and had hunted our guns in even colder weather. It was not lubes/greases gelling and causing the failure to fire. He can't be sure how many rounds total his VersaMax had through it (he had purchased his used, before I'd even met him), but he had shot less than 500 shells through it himself. When we both tried our VersaMax's the next day (after the thorough cleaning), we both had the same frequently intermittent "click... no bang" soft primer strikes. Again, when I fed the same shells with light indents into my backup gun, & again, they went bang. So it was clear the issue was the gun... not the lubes... not from failing to clean per the owner's manual... and strangely at that point both VersaMax's had the same issue. So while most malfunctions of well made firearms are related to poor service/cleaning/lubrication... or poor quality ammo, something else was wrong with both our VersaMax's. Obviously I had missed something during the tear down and cleaning. My mind raced about bad chambers (checked that: no finish issues, no burs, nor crud, nor corrosion) and everything else possible causing the issue. I'll save you the grief of all the posts online I read, and things I thought it could be, in my search for a solution. Once I knew what to look for it was pretty obvious (and was the same on both guns). So if you are getting soft primer strikes, and have been cleaning and lubing per the owner's manual with good cold weather lubes, here's what 3 things almost certainly are the issue and how to fix them: Problem #1: The original Bolt Cam Pins from Remington don't hold up and it seems Remington left burs in the bolt carriers cam pin slot. I'm convinced the original Remington cam pins are too soft to last. To determine the state of a cam pin: follow the Remington owners manual's procedures (only work on an unloaded firearm) to remove the barrel and remove the bolt assembly. Then use the manual's procedures to tear the bolt assembly down. Remember the firing pin is under spring tension and will shoot out! That is why Picture 23 shows a thumb holding the Firing Pin while the Retaining Pin is removed. Clean & inspect all parts. Inspect the cam pin and the slot it rides in the bolt carrier for deformation. (see pic of damaged cam pin) Look for burs on the slot machined into the bolt carrier (that the cam pin rides in). Again: while you got the bolt carrier apart, make sure there are not any burs in the bolt carrier's cam pin slot. Replace worn cam pins, and remove any burs in the carrier with some emery cloth or a fine round file. I, like most others, consider the Benelli Cam Pin to be a better solution in the VersaMax than buying the Remington part. Even if you don't find any deformation on an original Remington cam pin, I recommend replacing it with a Benelli cam pin... and lubing it well!  I found a wear mark on my bolt where a bur in the cam slot in the bolt carrier wore on it. I buffed the gouged area of the bolt smooth. Then I took a tapered round file and removed the bur with a file. REMEMBER: It doesn't take much filing or polishing with an emery cloth, sand paper, or fine stone to remove burs or to polish out gouges. You don't want to remove too much metal! You can check your progress with your finger nails. You may have to use your little finger inside the bolt carrier to check for burs. It must be emphasized that the owner's manual didn't tell you to lube the cam pin. This further accelerates the wear this area sees. Though I must acknowledge the new RemArms V3 shotguns come with an extra insert warning shooters to grease bolt carrier cam pins. We can only hope whenever the VersaMax2 comes out, RemArms will clarify the need to lubricate the cam pin. It is commonly held amongst competitive Benelli shooters that the Cam Pin's slot in the bolt carrier should be lubed with grease. Greasing cam pins works well in warm weather, but can be a bad idea for hunters who typically are out in the cold. The USMC M1014 service manual says to use "medium" lube on the cam pin every 500 rounds. USMC "medium" lube is putting BreakFree CLP on it such that "doesn't run down the side when turned vertical." Then the USMC M1014 service manual specifies even thinner oil in extreme cold. I'd suggest hunters omit the grease and lube the cam pin well with a good gun oil like BreakFree CLP, RemOil etc. The main thing is to lube the cam pin with something that will not gel in the weather you expect to shoot your VersaMax.  I replaced my cam pin with a new Benelli Cam Pin. The Benelli Cam pin was highly recommended on all the forums I visited, and has been working well for me. But you aren't done once you find and replace the bad cam pin. The new Benelli cam pin did reduce the frequency of light strikes, however my next hunt I still had a few light primer strikes. So it wasn't solved. From this I learned every VersaMax owner having light primer strikes needs to also deal with problem #2 below. No matter the condition of the cam pin. These pictures were excerpted from the VersaMax owner's manual. The numbers with red lines show where Remington directs one to use Rem Action Cleaner to clean the trigger assembly. Line 4 shows the hammer. In the other picture the left thumb is resting on the hammer to gently release it.  Problem #2: The original Remington hammer, hammer spring, and plunger are prone to fail. I have heard that some of the very first VersaMax's had some sort of recall issued because of poorly made hammers. But it seems that even the later Remington hammer version doesn't hold up. Both my shotgun's and my buddy's shot gun had peened hammers. To determine the condition of the usual suspects in the trigger pack, use the owner's manuals instructions to remove the trigger pack from the action, & clean. Then using gunsmith procedures (not in the owner's manual), remove the Hammer, Hammer Plunger, and Hammer spring from the trigger assembly. Be careful! There are lots of small parts in the trigger assembly that are easy to lose and the hammer plunger and spring will shoot in your face or all over the shop if you aren't careful. Also the "D" clip pin that holds the hammer assembly together isn't intuitively removed until you see how it's done... and it's easily damaged or lost. Some times you will see this clip described as a C clip... whatever you call it: we also offer replacement D or C clips for sale.  Once I got my Remington original hammer plunger out, I saw that it was chrome plated, but the plating was chipped off. This created a mess of abrasive hard chrome flaked crud that jammed up the plunger. You couldn't see this crud nor remove it when the hammer plunger and spring were in the housing. Moreover the edge of where the chrome was chipping off would bind, slowing plunger when the trigger was pulled. And that brings me back to items we sell: -Benelli Cam Pin -Benelli Hammer -Benelli Hammer Spring -Benelli Hammer Spring Plunger/Cap all the parts needed to fix this issue in a VersaMax are frequently called "Remelli" parts): You might think doing all four is over kill. I'm convinced it's not overkill. It's not wise to pick at any problem and wait for it to get worse when its understood and predictable. While you can see peening and deformation of the face of the hammer without disassembling the trigger assembly, you cannot tell if the chrome of the original Remington plunger is pealing without removing the plunger and spring. Nor can you clean the hard abrasive crud the chrome turns into from the assembly, unless the hammer spring & plunger are removed from the trigger pack. The best course is to tear it down once and fix it all while you are in there. Again, even if some of these parts are ok, experience shows that they will eventually fail as noted above. No matter the original parts' condition: I'm convinced the best fix is to, tear it all down, clean, replace the Cam Pin, Hammer, Hammer Plunger, and Hammer Spring with Benelli components, and lube. After that there typically isn't much more that needs to be done besides standard regular maintenance (that the owner's manual didn't tell you about... we'll get to those details later... keep reading). I realize that diving into problem #2 above is probably beyond most folks comfort levels and even the owner's manual lists it as something to have a gunsmith do. I figured it out by watching YouTube videos on how to work on Benelli trigger packs (the Remington is a clone). I've been working on my own guns since I was in elementary school, so this sort of stuff doesn't scare me. If tearing down a trigger pack is beyond your comfort level: you can purchase our new service and ship your shotgun's trigger pack to us: The service is simple: - Add our "Remelli Parts kit" to your cart - Add "send us your trigger pack - labor only" to your cart - Complete a check out (and get us paid) - We'll hold all the parts and other items that were purchased as part of the order whenever we see the install service purchased. All you have to do is pull the trigger assembly from your VersaMax, pad it well, & ship it to us. - We will send the trigger pack back with the new cam pin, and anything else you purchased. You put the cam pin in your bolt assembly yourself... the directions for tearing a bolt assembly down are in the owner's manual. REMEMBER: if you want your old parts back, let us know with a note accompanying the trigger pack (or they'll just end up in my recycling bin). Problem #3: Gummed up recoil spring &/or weak recoil spring On this one, the recoil spring may be gummed up... (or less likely, the spring may have weakened... or both). During my hunt I didn't have the tools to take the recoil spring assembly apart. As a matter of fact, I'd never cleaned the recoil spring/action tube. I had put good lube in there and cycled to bolt, but I regret that I never took the recoil spring and plunger out and cleaned them. Now I do it as part of my regular maintenance. I've learned that If I don't clean it, and it's cold, the crud in there will gel up and cause light primer strikes all on their own. Unfortunately the following procedures and the requirement to clean and lube the recoil spring were omitted from the Owner's Manual. So here's how I'd proceed to address issue #3: To clean the recoil spring: 1. On an unloaded gun, use the owner's manual procedures to remove the barrel, bolt assembly, and trigger assembly from the action. Warning failure to remove the bolt assembly from the action can make removing the recoil spring a very difficult and somewhat dangerous task! 2. Use a Phillips screw driver to remove the two screws holding the butt-pad to the buttstock. A little spit on the screw driver tip helps get it in the small rubber holes of the butt-pad. Then, use a 3/16 hex drive (commonly called an "Allen" drive) to remove the buttstock from the action/spring tube. 3. Use a 19mm (or 3/4") 6 point socket or wrench to remove the retaining cap keeping the recoil spring trapped inside the action spring tube. BE CAREFULL THE 19mm CAP IS UNDER SPRING TENSION. WARNING: ITS UNDER TONS MORE IF THE BOLT ASSEMBLY WAS NOT REMOVED IN STEP 1 ABOVE! 4. Remove the spring and action plunger from the tube. 5. Thoroughly clean the tube, spring, plunger, and the receiver. Apply gun oil that won't gel in the cold to the plunger and a few drops inside the tube (BreakFree CLP, RemOil etc). 6. Clean, lube, and fully reassemble the shotgun by following the procedures above in reverse. So, the action spring may be ok, or it may be worn out. If there was a bunch of crud in there, I'd probably try the original spring with the Remelli parts kit (to correct issue #1 and #2 above). I've seen where a 'gunked-up' action spring will work OK in warm temperatures, but cause light primer strikes in the cold (and the action spring was OK). If the spring was worn out, it probably wouldn't work in any temperature. Noting that the gun only has light strikes when cold soaked typically confirms that the recoil spring is probably gunked up but otherwise is ok. Cleaning the recoil spring regularly removes this probability. So, If I continued to get light strikes after fixing #1 & #2 with a "Remelli Kit", and thoroughly cleaning and lubing the action spring at every cleaning... that is when I'd replace the action spring. Remember: Light strikes can result from the bolt carrier not being pushed fully forward... and the action spring does that. But also, #1, #2, and a dirty action spring are the typical primary culprits, not the action spring being too weak. Some folks want to put more powerful springs in the action spring tube. I don't think that is wise as it can cause issues with low powered trap/skeet (low-brass) ammo. Putting a heavier recoil spring in jeopardizes function with light loads. Fiddling with stronger or lighter springs anywhere in the gun can cause issues. It's a well engineered delicate balance of forces. Replacing the old spring with a factory original action spring should bring the gun back to similar factory new performance, but replacement is only necessary when the action spring is cleaned and lubed and still generating light strikes. Thus, replacing the recoil spring may be warranted, or it may be over kill. We offer them as a separate item to meet your desire. Either way cleaning, evaluating, and perhaps replacing the action spring is something you will have to do yourself, as we aren't interested in shipping/receiving guns/receivers. Removing, cleaning. and lubing the action spring should be part of your regular maintenance. Swapping it while you are in there is easy. Bottom line to keep a VersaMax running: Some of the Remington original parts wear quickly & fail. Action springs get gunked up, and springs eventually will wear out. Do the maintenance, evaluate the parts, and replace the primary culprits as you see fit. Our recommendation is to start with fixing #1 & #2 with our "Remelli Parts kit", then cleaning the recoil spring and shoot it to see if the light primer strikes persist... then -if- after putting the "Remelli" parts in, you continue to get light strikes on a clean action spring, you need to fix #3 with a new action spring. But you could just replace the action spring right along with the other parts. It's up to you. FIXING #1, #2, & #3 FIX 99% OF THE VERSAMAX'S OUT THERE... IF YOU ARE CLEANING & LUBING PROPERLY AND RUNNING THESE NEW PARTS AND STILL HAVING LIGHT PRIMER STRIKES, THERE IS PROBABLY SOMETHING WRONG THAT REQUIRES A SKILLED GUNSMITH'S ATTENTION Got suggestions? Lessons learned? Think I'm full of it? Did our products help you? Post a comment below to let us know!

Or if you are shy & don't want to discuss stuff publicly call us at +1 989 795 2526 or use our contact form to initiate an email conversation.

0 Comments

Thanks for visiting the The Badger's Den (the blog for Badger Ridge). If an internet search brought you here looking for muzzleloader solutions, please stick with us: we have the solution to your Remington 700 ML/MLS and Ruger 77/50 woes. I update this blog frequently and what you are looking for is probably one or two clicks away. This blog is sorted categorically and chronologically. So you can find what you want by looking in the appropriate category, or if you know when it was published, you can use the time line. Or just keep scrolling down! If you are new to our site: YES WE STILL SERVICE AND CONVERT THESE OLD MUZZLE LOADERS But for this installment I'd like to tell you about: A new product we'd like to share with you! Pigeon Decoy Shells!I tend to turn what I've learned from my hobbies into our products. In this installment I'd like to share a product that helps me better enjoy one of my Off-Season passions: Pigeon Hunting. We are pleased to offer what I believe is the best compromise between effectiveness, low cost, rapid setup, and portability: Pigeon decoy shells. A Brief Overview of Pigeon's Origin, Habits, & IDIn the United States: pigeon are feral (non-native). A long time ago what we call pigeon were domesticated from Rock Doves, and then eventually brought to the US. Pigeon are raised by many enthusiasts, and released in races and tournaments. Thus pigeon don't have a huge fear of man and will graze near us and our livestock. Just like their Rock Dove progenitors who nested in rock cliffs, pigeon are cavity nesters: so they tend to roost under cover, in old buildings with horizontal ledges. They will hatch and raise young all year round provided there is sufficient feed. Being feral, most states don't regulate pigeon harvest, set limits, nor establish seasons. As feral species compete with native species for resources, most states encourage harvesting them as much as possible, year round. Check your local regulations to be sure. Here in Michigan a base (small game) hunting license is required to hunt pigeon, but there are not any seasons nor bag limits. This makes them excellent off-season fun. To the untrained eye, pigeon and dove look a lot alike. The fact that in Spanish the two birds are called by the same name ("Paloma") says a lot about the two. Not to mention the lecture on taxonomy you could get from an ornithologist that would be mixed with the words dove and pigeon referring to closely related birds. However, it is not hard to learn to quickly distinguish one from the other. Its always important to be able to accurately ID your target. Especially because mourning dove are a North American native migratory species, regulated federally, and also by each individual state. Here in Michigan, it is prohibited to hunt mourning dove (which I call 'dove' frequently in this post). In most other states mourning dove may be hunted in season, with a bag limit, and migratory bird license. Also many parts of the US have additional types of protected doves. A hunter must be able to distinguish between them and pigeons. Pigeon are larger and more plump. Mourning dove tend to hang out on power lines, small tree branches, and will nest without a roof. You will find pigeon sitting on ledges, roof peaks, etc. If you see a pigeon in a tree, it most likely will be closer to the trunk on the fatter part of the branch. The two have drastically different calls. When flying mourning doves tend to sound squeaky, while pigeons have a flapping 'rapid clap' sound, especially when they light or land. I find pigeon wing beats to be erratic and 'floppy' while dove are more rhythmic and snappy. When lighting or landing, its easy to see a pigeon's 'squared off' tail compared to a mourning dove's spearhead shape. There isn't much variety to the dove's dull brown speckled plumage. A pigeon may look like the examples here, or have various white, auburn, and other color variations.Pigeon, just like dove, taste great (I was fortunate enough to live in states where I could shoot dove). The meat is called "squab." Notably squab can also refer to their young... aka pigeon/dove 'chicks'. Their meat is frequently referred to as 'filet mignon of the sky' by us rednecks, as they have dark breasts that when removed look and taste like little slices of back strap. Like waterfowl, pigeon tend to have daily routines. I've found hunting pigeon to be much more like hunting the feed for waterfowl than any upland bird. First, they start their day at the roost, hungry. Unlike freshwater waterfowl, they probably thirst along with their hunger. Having worked their way through the contents of their crop all evening (the expandable pouch in their neck where they store food), they are hungry in the mornings. If they have young, they need to find food then return to the roost to feed them (both the male and the female tend to the young). Somewhat unique to pigeon, siblings will also participate in feeding their younger kin. So once daylight has arrived, they fly off the roost in search of food, and sometimes water. They may return quickly or stay out for the day. With pigeon, hunting the roost is fun and can be very successful, especially after they have fed and desire to return to the roost. But most roosts are close to man, and/or man's livestock. So hunting the roost may not be an option. That typically leaves us hunting the feed. Like many waterfowl, their preferred feed is cut crops. Modern mechanical harvesting has been a blessing to these seed feeders: A portion of the crop is lost and spread over the harvested field. You will tend to find pigeon there. In late summer look for cut wheat, in Fall add harvested corn and soy beans to the list. Also, pigeon will go to roads and other areas with small gravel to get grit for their gizzard. But I've not seen them stay there for long. I've also seen pigeon feed off of spread cow manure. It seems they find the undigested seed in the manure and are happy to pick through it. In my area the Amish plant and harvest organic wheat. Their old-school process of cutting, binding, stacking, drying, and then bringing the wheat in hardly loses a seed. I rarely see pigeon on their cut wheat fields, but I've found them in their silos, and livestock watering holes. One Amish family really likes it when I bring them walleye... you will almost certainly have to talk with the eldest male to get permission. If you are a man, don't expect the women/girls to say much to you. How to Hunt Pigeon A successful pigeon hunt will probably involve: -1. Scouting where they roost: look for buildings, silos, grain bins, with cover and access holes in the sides. If you see pigeon on the edge of a roof or opening, chances are there are more inside. -2. Finding the available feeds, watering holes, and grit. You will probably find the same feed used by dove, ducks, and geese. You do want to observe pigeons on the feed to know what field they are in using. I've seen plenty of fields filled with dove that pigeon pass right by. Sometimes finding pigeon is easy, other times you have to sit a while to determine their movement. -3. Getting access: Once you see their patterns, and understand their daily life, try to get access to those places, set up a hide with decoys, and be ready for fancy flying! Bringing a kid along has improved the number of landowners I've gotten "YES" from. Pigeon are very social birds. I've watched pigeon bypass a very good feed to join a flock on another field with poor feed. The only reason I could come up with for the behavior was a socially driven need to congregate. Thus hunting the feed or waterhole is all about setting up visible decoys in the right spot and getting a little bit of cover. More Specifics on our DecoysI've found our decoy shells just plain work. They are a great balance of effective, light weight, portable, and quick setup/breakdown. Each shell comes with a stake that make them a bit higher than a standing pigeon. This is good: it increases visibility. You want your decoys above any stubble or vegetation that could block them from view. When the shell is sitting on the stake they also have a little bit of a bobbing motion. This is pronounced when facing into or directly out of the wind. The decoy shell has two rectangular holes for the stake. Using the forward hole pivots the shell upwards: like a standing erect pigeon. Using the back hole pivots it downward like its feeding. You can set your spread as you like. I like to set mostly feeders with one erect. Also, when hunting really tall stubble, you can omit the stake and set the shell right on top of the stubble! Pigeon aren't all that smart: they don't need 100% perfect reproductions to be decoyed by them. Moreover, due to domestication, there are so many variations to their plumage there is no such thing as 100% accurate decoys. But again decoys are sold to hunters, not birds! While there are other much more expensive, less portable, finely painted decoys out there: they are not any more effective. I'd argue they are probably less effective because they are smaller, shorter, and don't bob in the wind like our shells. The flat card silhouettes featuring pictures of pigeon are also inferior to our shells. Remember: Effective decoys must 'look like' pigeons from all angles and not be covered up by stubble so they can be seen. I've played with patterns while hunting and I've settled on two simple ones: Light and Dark. Most pigeon plumage are a variation of our dark theme. The lighter plumages are recessive traits, thus you only want a few of the light theme in your decoy spread. Hence, our 6 pack of shells comes with 5 dark theme, and 1 light theme. I am confident that you will find our shells work. They are bigger than a normal pigeon. Waterfowlers will quickly recognize that is a good thing. The better decoys in waterfowl hunting are also bigger. Size matters: bigger means that the decoys can be seen from further away. Birds are fine with giants: So long as the giants look like pigeons, pigeons will decoy to them. How I hunt with our Pigeon Decoy ShellsI set my decoy shells about 20 paces out from a bush, fence row, high stubble, or other cover. If I can find shade in the summer I'll sit there! Sitting in the shade while the birds fly in the sun helps hide the hunter. While pigeons aren't as wary as many other game birds, you will have more success wearing camo, hiding, and blending in. Blinds aren't required, but you can use one if you want. A blind certainly won't hurt. For me, it is better to be mobile than to have a fancy blind. A Great Youth Hunting OpportunityAs a parting thought, I'd also like to encourage bringing a junior hunter along (preferably once you have your set-up figured out and can provide them with a good hunt). Pigeons are pretty forgiving of rookie mistakes, and you can bring them in close to kids just by setting the decoys closer. Let 'em land in the decoys if they will. It doesn't get any better for a youngster with a 410. I give my son first shot... then I bat clean up. Don't be surprised when they keep circling the decoys after being shot at. They are pigeon after all.

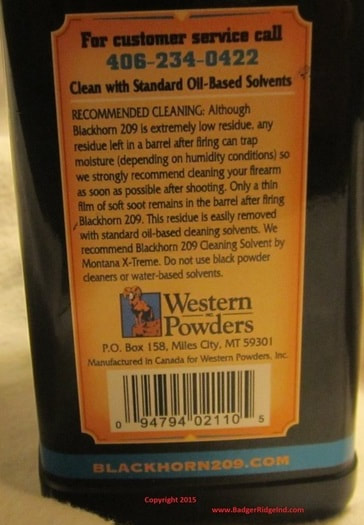

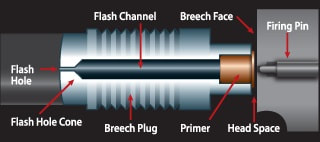

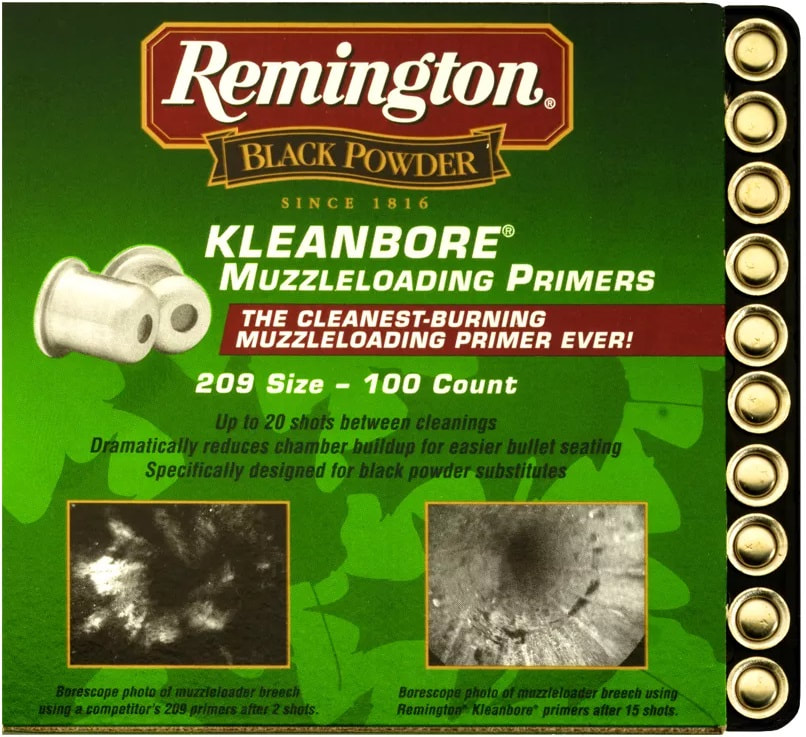

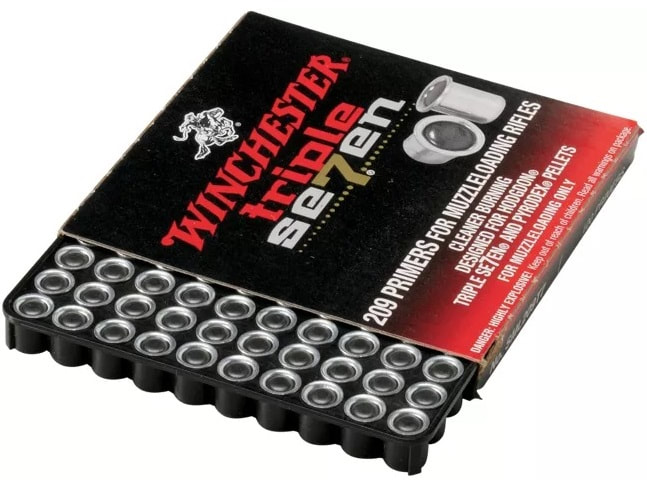

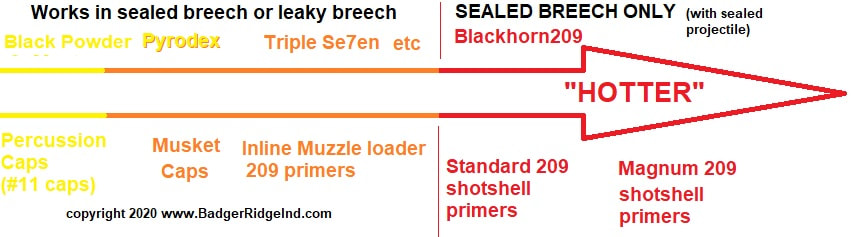

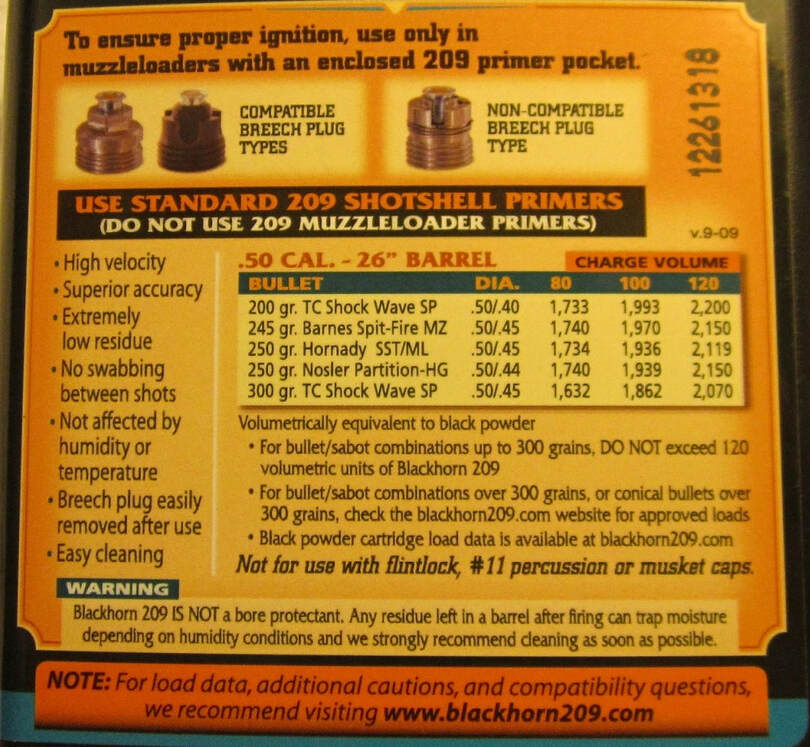

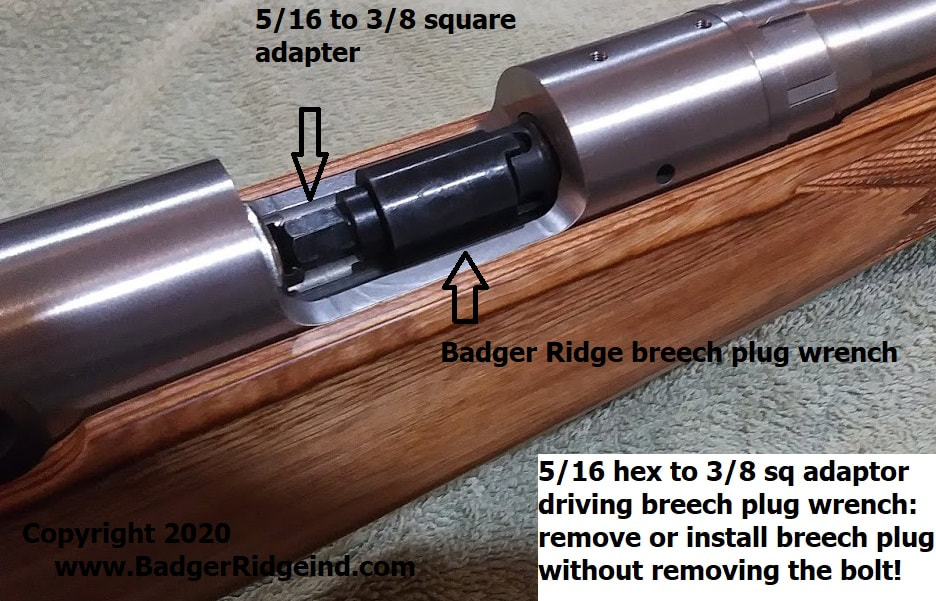

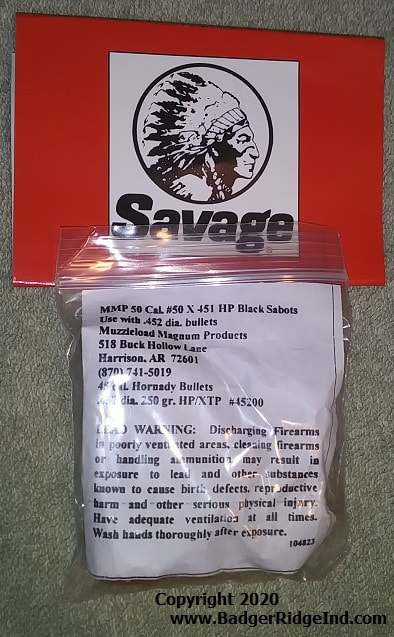

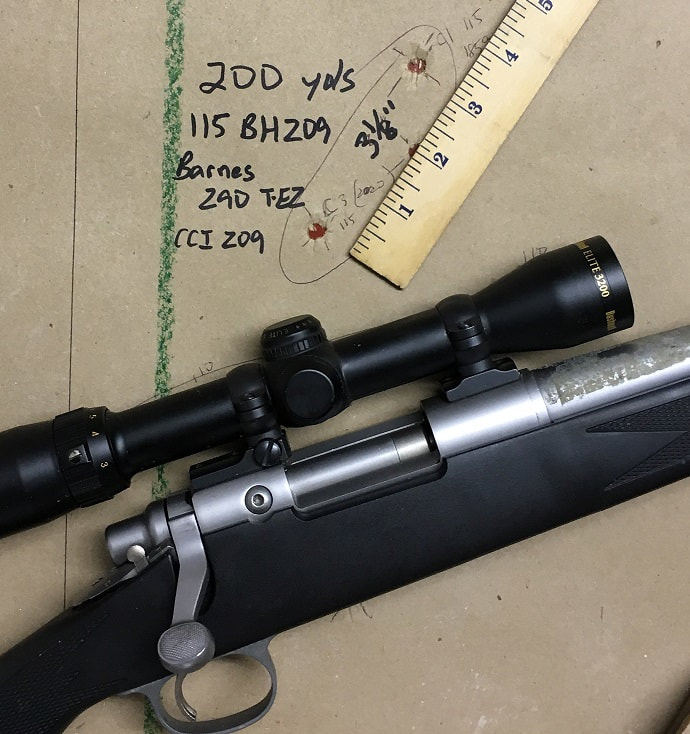

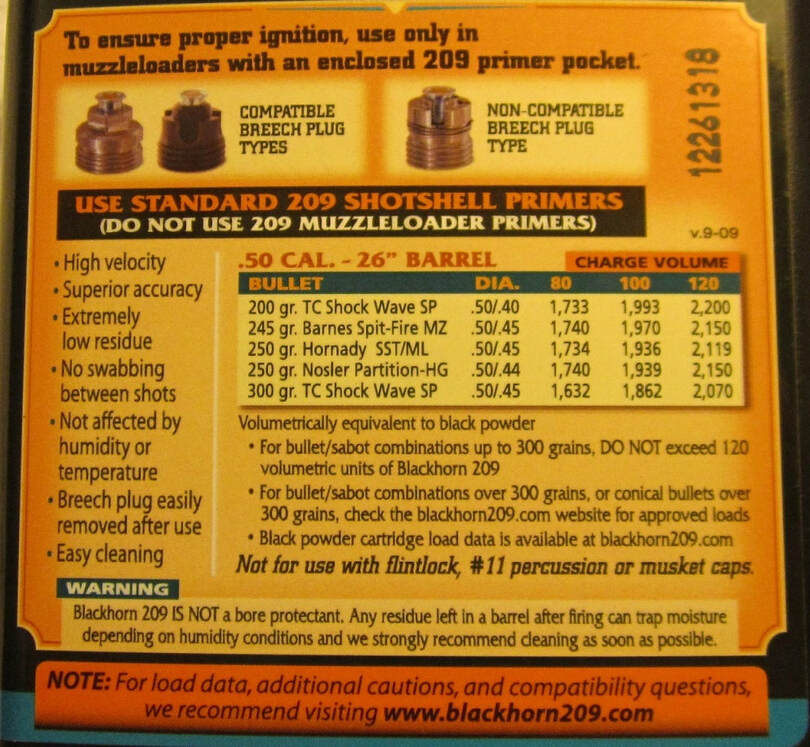

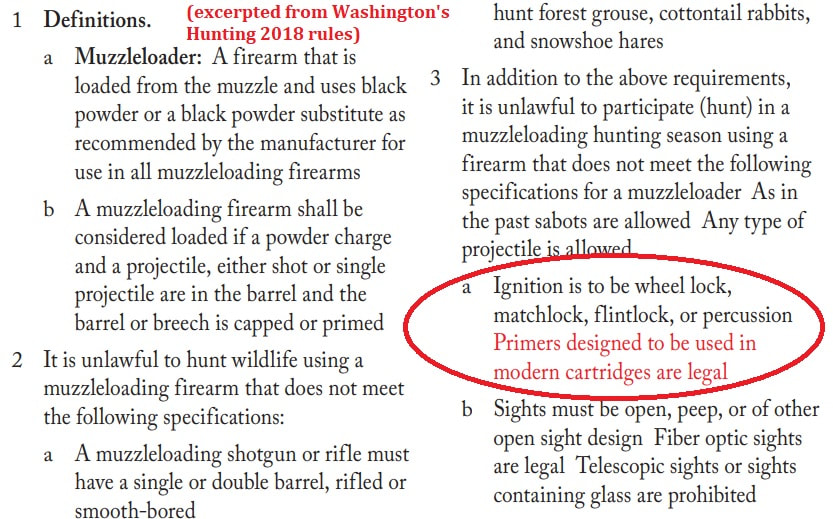

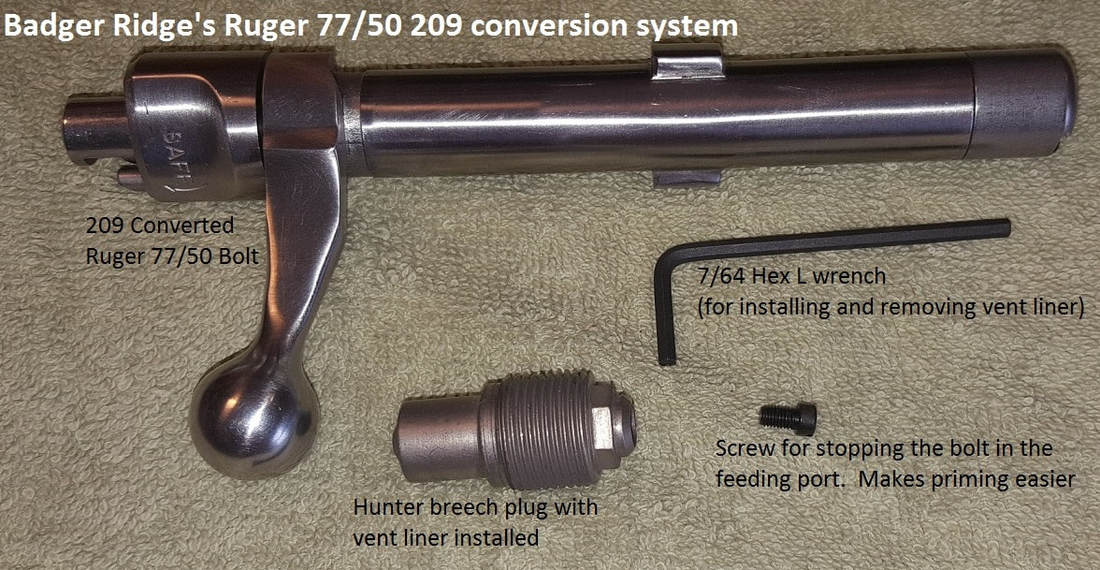

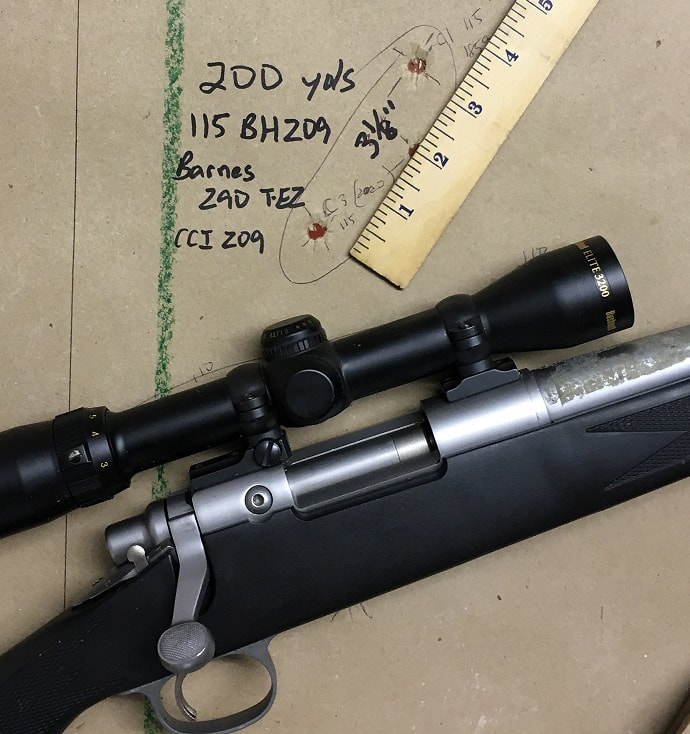

Got suggestions? Lessons learned? Think I'm full of it? Did our products help you? Post a comment below to let us know! We've been selling and installing our great 209 conversions for years now. And I've noticed my questions and sales following trends influenced by the various hunting seasons and their associated rules. This time of year many folks are getting ready for Colorado's muzzle loader season, typically focusing on harvesting an elk. So annually, I edit and re-post this one. The commentary here was also added the to the FAQ (Frequently Asked Questions). The FAQ entry: Q: I hunt in Colorado, sabots are not allowed for hunting during muzzle loader season. I want to use your awesome 209 conversion, but you say you recommend sabots with jacketed handgun bullets. What are my options? A: Short answer is our kit will work great with any projectile. I've found Pyrodex, Triple Se7en, and black powder work best with non sabot projectiles. So I suggest that you use our kit and any muzzle loader safe powder (besides BlackHorn209) for your Colorado hunts with Colorado legal projectiles. Long answer: I realize not all 50 state have the same rules. And some state’s rules are just plain silly. I wrote a blog post about that. The main thing to remember here: the powder you chose must be compatible with the projectiles you use. Our kit will seal the breech, which keeps the crud out of the bolt and action no matter what muzzle loader safe propellant you chose. Our kit is compatible with all muzzle loader safe propellants: pellets, loose powder, etc. Also using 209’s will give you more ignition heat and thus more reliable ignition over caps. And seeing our system keeps the crud sealed into the breech plug, the 209 is ignited reliably too. But the powder and projectile choice is up to the shooter. Read the manuals/instructions and follow them when developing loads. Blackhorn209 powder is different from Pyrodex & Triple7even: To be reliable BlackHorn209 needs to be fully sealed; i.e. sealed at the breech (which our kit does), and sealed at the projectile. Minnie balls, minet, power belts, B.O.R. Lock MZ and other easy loading projectiles that are legal for Colorado muzzle loading, don’t usually seal until the powder combusts and forces them into the grooves. This deformation sealing the bore after combustion is called obturation. The problem is BlackHorn209 doesn’t burn well until it’s sealed and can build pressure. So it’s likely to have bloopers, miss fires, and hang fires with obturating projectiles. Sabots seal well to start, thus if you are using BlackHorn209, it’s recommended to use sabots. Though the new Hornady Bore Driver bullets are reported to seal well and work with BlackHorn209, I haven't tried them myself. Never use smokeless powder in your Remington/Ruger! It says it right on the barrel! Because Colorado doesn’t allow sabots during the muzzle loader seasons I would stay away from Blackhorn209. (or with a lot of trial, I may try the Hornady Bore Drivers) Otherwise, If I was hunting in Colorado, I’d use our kit, choose a heavy projectile (250gr or more) that seals on ignition: Hornady BoreDriver, Thor, minie ball, lead conical, etc. But without a lot of testing, I wouldn’t use BlackHorn209; I’d try Triple7even, or Pyrodex. Although they are not as easy to clean, and will foul the barrel, they are very easy to ignite even when not sealed, and will obturate the projectile. Black powder will work just fine with these sorts of projectiles too. I do have a few clients that report success with Blackhorn209 and magnum primers (CCI 209M or Federal 209A) using Hornady FPB’s or its aformentioned replacement Bore Driver... and also with Thor bullets. I also had one that said tthe Thors worked well at the range, but didn’t fire when he had a nice bull in his sights. He said it was extremely chilly that morning, his rifle was cold soaked, and the Blackhorn209 wouldn’t go bang. He was very frustrated. I suspect it was because the projectile shrunk with the cold, and the copper jacket wasn't quite as malleable. Also cold powder is just a bit harder to get burning, and thus that setup was unable to obturate the looser projectile and keep the BlackHorn209 burning. Thus without a lot of testing (like putting a loaded rifle in a freezer, pulling it out and shooting the combo... repeatedly). I would stick with Pyrodex or TripleSeven for Colorado muzzle loader hunting: they will go bang with an obturating bore riding projectile when you need it, even when it is very cold. Just about everywhere else, I recommend sabots because they have been accurate, easy to load, and jacketed hand gun bullets have always been very effective for me. Whatever powder you chose, the velocities your muzzle loader will produce are essentially the same that good jacketed hand gun bullets are designed for. They tend to kill quickly and bring home game. Sabots are allowed in most states, so that's what I usually recommend. Long-term: If I voted in Colorado, I’d pressure my legislature to change the muzzle loader rules. Removing the most effective projectiles (jacketed hand gun bullets are great in muzzle loaders), and the most modern muzzle loading propellant (Black Horn 209) from use is bad for the game receiving the projectile. I believe the no sabots rule promotes wounded/lost animals. Many folks find their way to this blog from a simple internet search. Frequently because they are having muzzleloader trouble like misfires, failure-to-fire, are tired of blow back, etc. Some just want to use Blackhorn 209 powder (which will misfire or blooper if not sealed up).

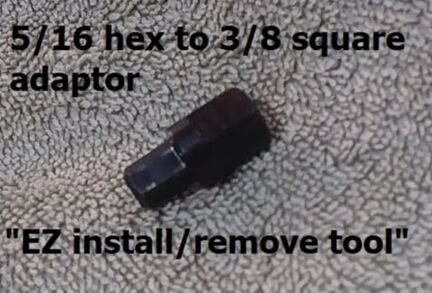

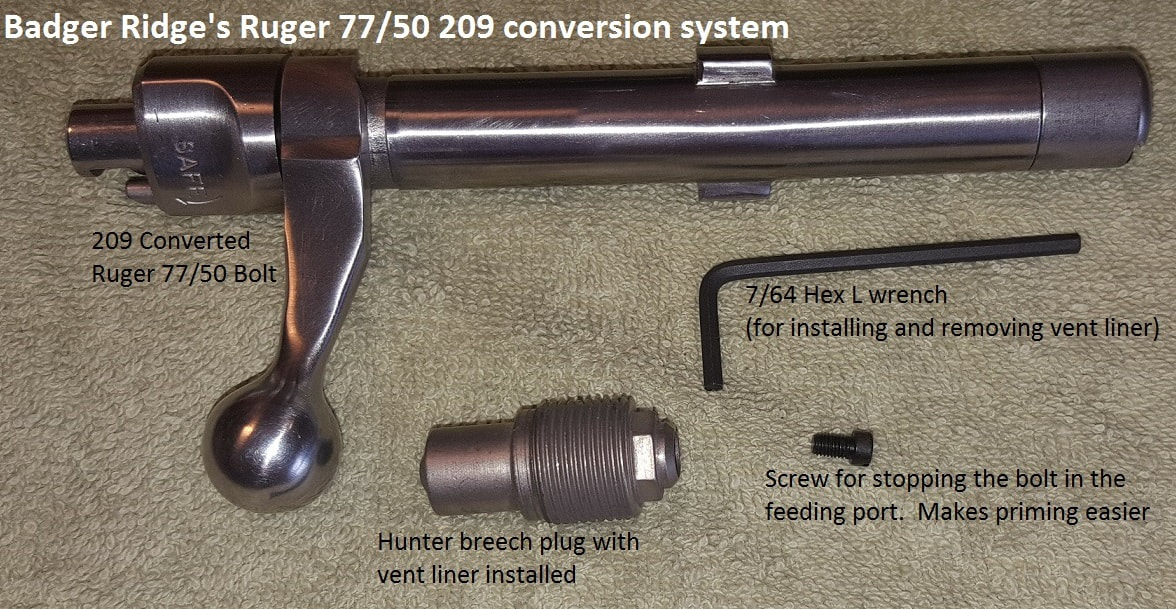

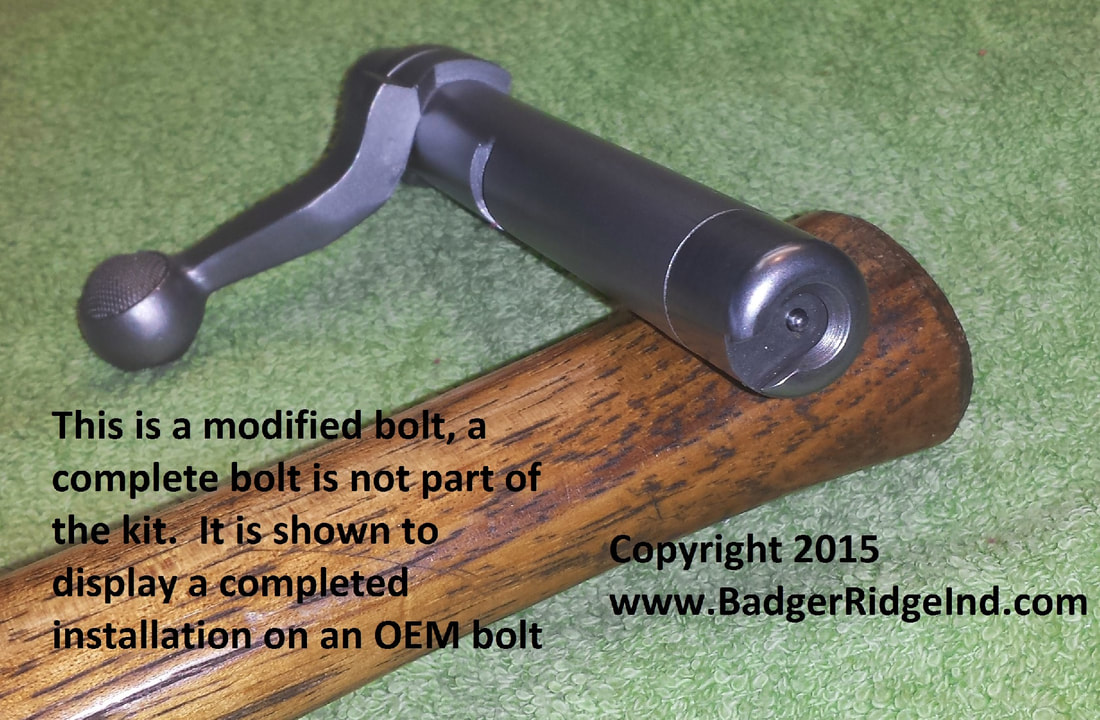

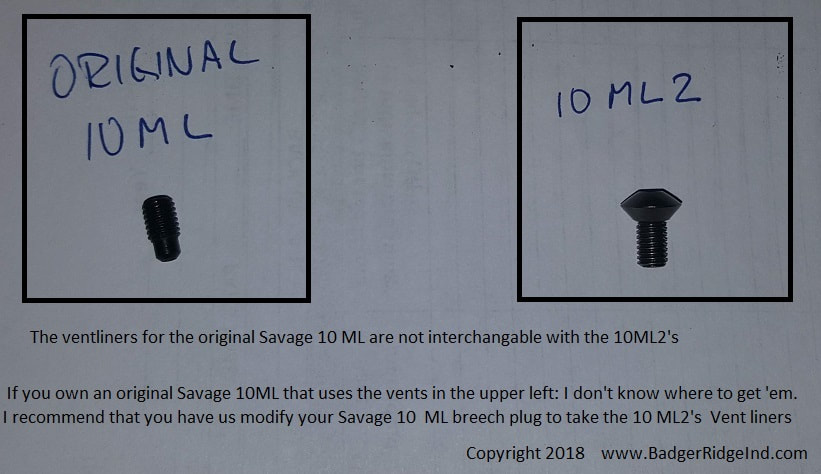

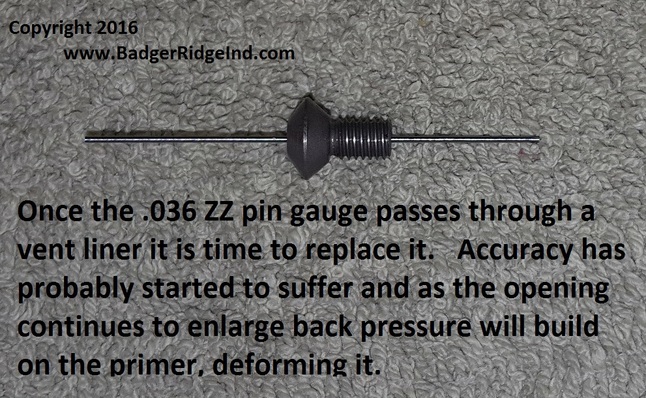

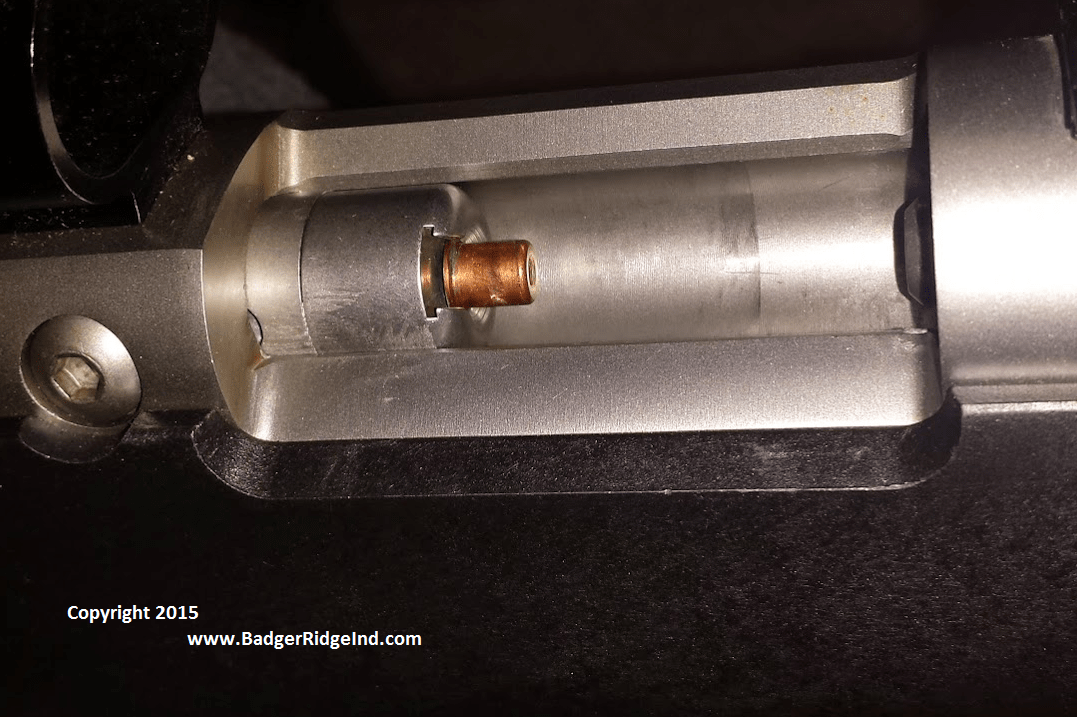

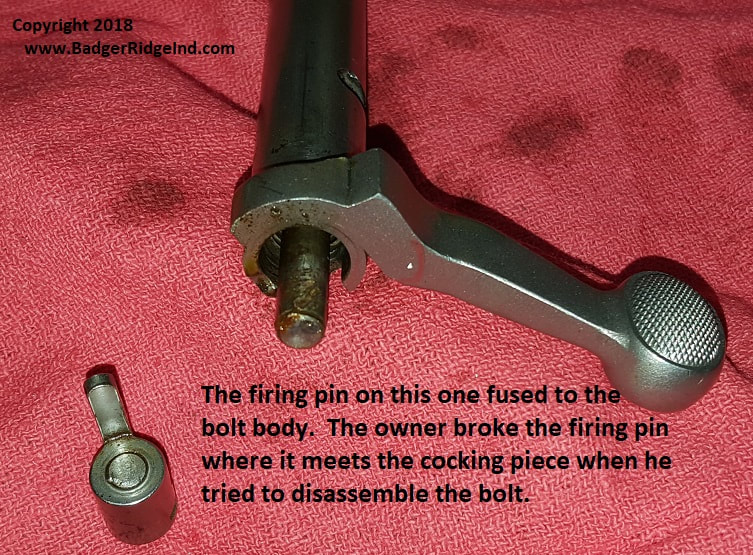

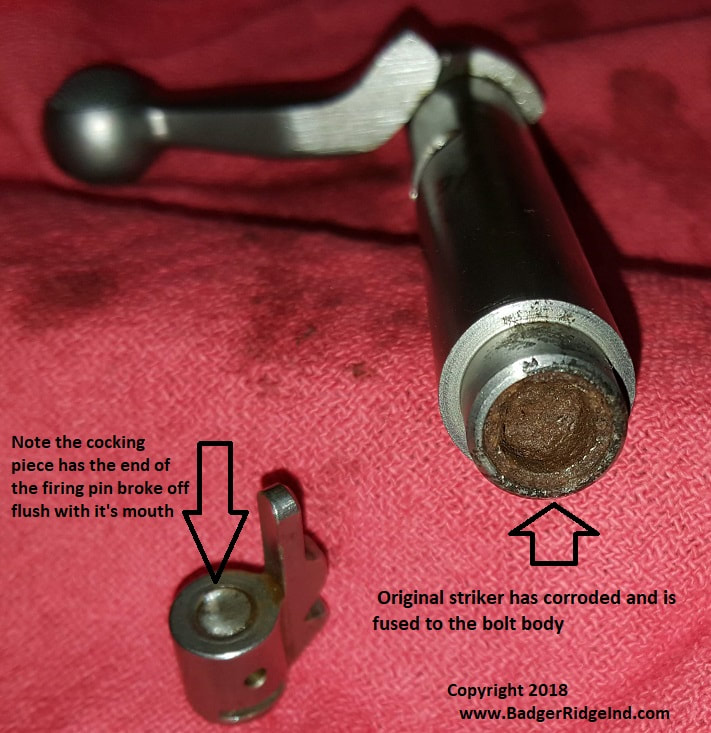

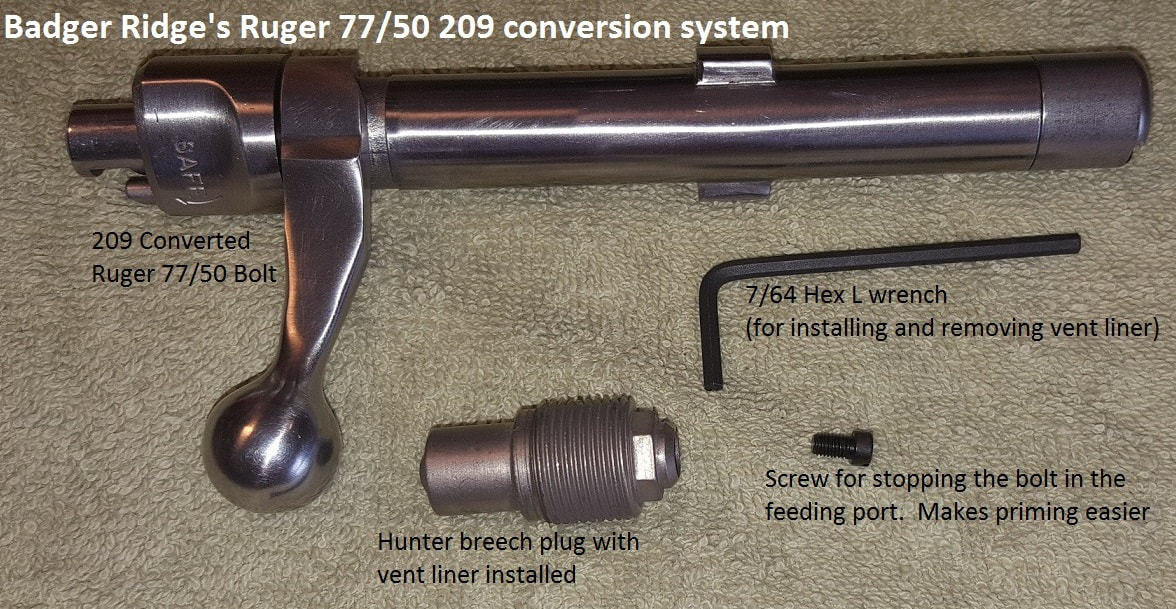

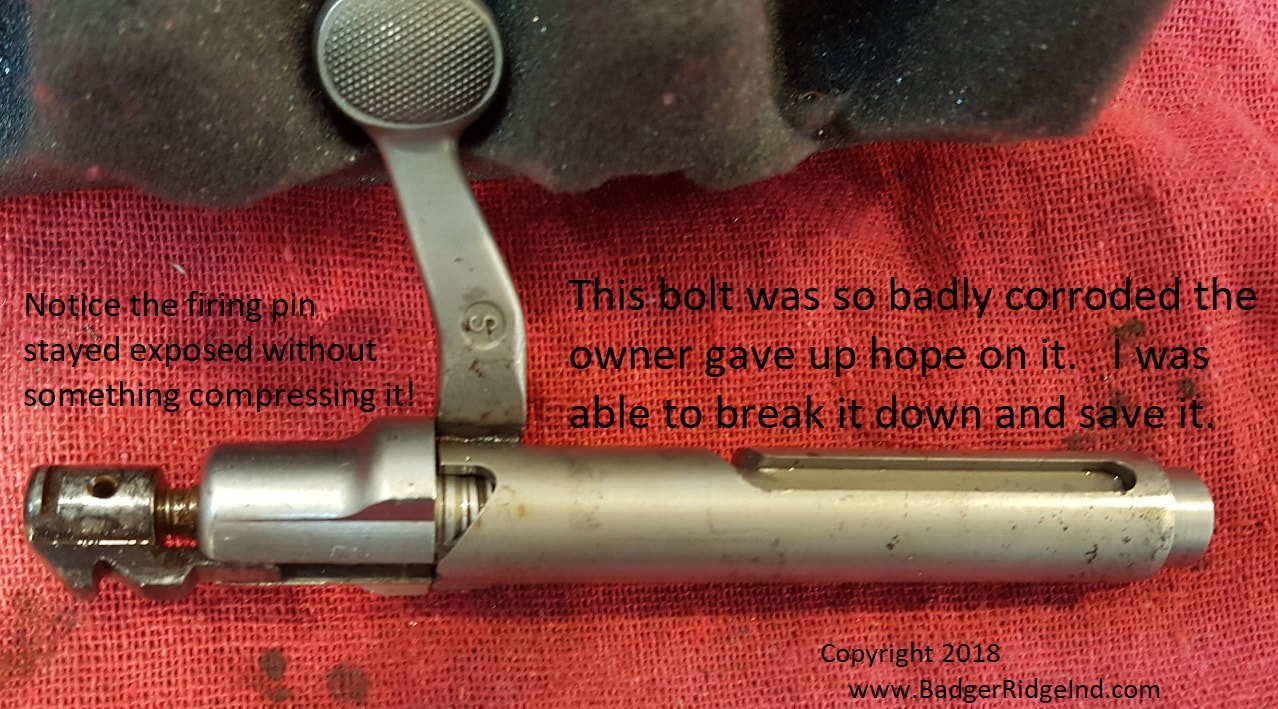

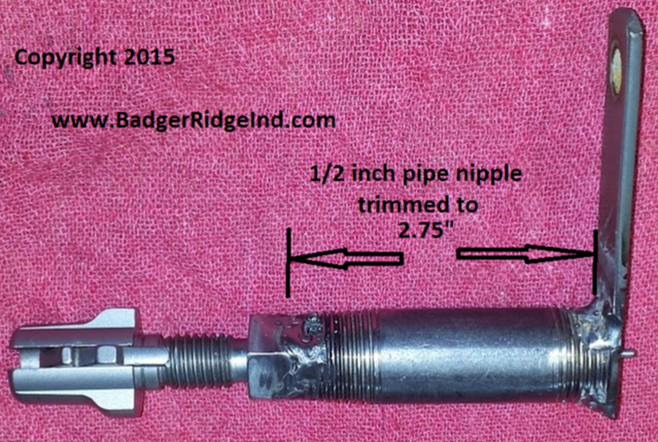

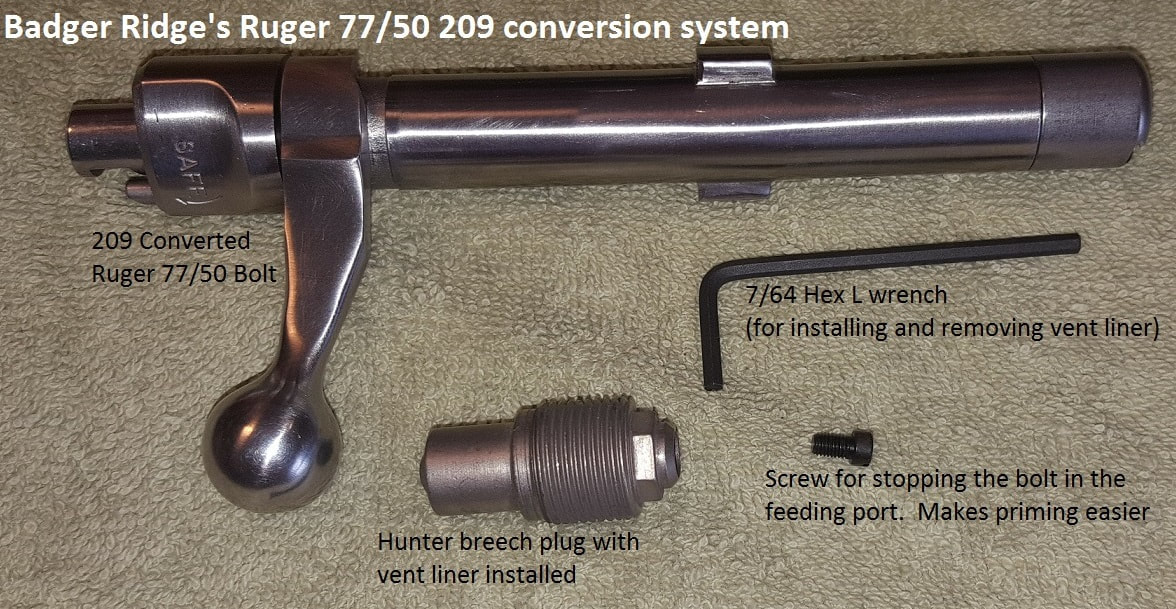

Other's have a friend that fixed his woes with our system, or saw a modified rifle at the range using our awesome 209 conversion for Remington 700 ML's and Ruger 77/50 rifles. Some just know that there has to be a better way, and there is: you found it in our kits. However you got here, and whatever shape your rifle is in, welcome to the best, last conversion you'll ever want on your rifle, and a great source for other hard to find Remington 700 ML parts. We have many products, but we do focus on the The Remington 700 ML/MLS & Ruger 77/50 muzzle loaders (both have been out of production for years now). These rifles now vary in condition. Some have hardly been used. Others used, but well cared for. Some have been neglected. So their condition truly runs the full gambit. This is further complicated due to the original design and other 209 modifications sending fouling corrosive gasses throughout the bolt and the receiver. New owners can be further confused by the various kits that may have been fitted over the years. Our kits fix blow back issues, don't rely on most of the parts people tinker with, and base line the rifle to a solid known good state. Yes, we are still in business, supporting your old muzzle loader and making it what it should have been. If an internet search sent you here, please keep clicking around until you find the solution you are looking for. But in this installment, I need to discuss our business in general. We are a small, family run, veteran owned, home based business. We do many things in house, and have some things mass produced by others. Really, it just boils down to trying to do things as efficiently and best as possible. We are still in the process of building/finishing a large workshop to grow into. This project has taken more time, energy, and resources than planned. Some of that is due to COVID/supply chain restrictions/inflation, and some of that is just my optimistic predictions on my own abilities and talents. We’re about to take delivery of much needed equipment that should allow me to begin retrofitting vent liners into breech plugs in house again. (This was being subbed out for a while, then we lost that sub/friend to cancer, and then suffered delays). Also its tax season (I’ll hold back from venting about our taxation system, and the time suck its been to our business), and many folks (more than usual this time of year) are asking for other things to get done (like bolt conversions). As I age, it seems I’m able to work a little less, and am spending more time tending to aches. So it just seems there isn’t enough of me to go around. I also like to hunt/fish, and we are a ‘family’ owned business. God & family comes first. Then my hunting/fishing. Always good to get the family hunting/fishing with me. All of this is slowing our production rates and increasing turnaround times. Your patience is appreciated. I guess I just want you to know, that we know, that some things are taking longer than they usually do, and we may not be living up to prior expectations. We know this, and are working as best we can to grow efficiently, while meeting demand. Please accept our apologies, and hope you can relate to our position. Also, prices of materials, and everything else is going up for us. So you will observe our prices move up as well. Inflation seems to be the sign of the times. All the above have slowed our development of new products and services (like the Austin & Halleck sealed breech 209 system, and some 3D printed items that have been suggested by our customers or are just rolling around in my head). Its also slowed revival of some of our stalwart products like Remington 700 MLS bolt bodies and complete new bolts. I won’t rush these. Quality is key to these sorts of products, and I don't have the time to do it all and get them all right... at least not right this minute. Anyways, thanks for your patience and understanding. We are glad that you are swinging by to read my excuses and rambling. Your patronage is appreciated. Your prayers for our efficient continued growth in these trying times are appreciated as well. As always, If you have questions or concerns you can call us (the number is at the bottom of every page of this website), or use the Contact Form to initiate an email conversation.  The Remington 700 ML/MLS & Ruger 77/50 muzzle loaders have been out of production for years now. These rifles now vary in condition. Some have hardly been used. Others used, but well cared for. Some have been neglected. So their condition truly runs the full gambit. This is further complicated due to the original design and other 209 modifications sending fouling corrosive gasses throughout the bolt and the receiver. New owners can be further confused by the various kits that may have been fitted over the years. Our kits fix blow back issues, don't rely on most of the parts people tinker with, and base line the rifle to a solid known good state. Many folks find their way to this blog from a simple internet search. Frequently because they are having trouble like misfires, failure-to-fire, are tired of blow back, etc. Some just want to use Blackhorn 209 powder (which will misfire or blooper if not sealed up). Other's have a friend that fixed his woes with our system, or saw a modified rifle at the range using our awesome 209 conversion for Remington 700 ML's and Ruger 77/50 rifles. Some just know that there has to be a better way, and there is: you found it in our kits. However you got here, and whatever shape your rifle is in, welcome to the best, last conversion you'll ever want on your rifle, and a great source for other hard to find Remington 700 ML parts. Seeing the guns are so old, most folks first question is: Does this guy really still sell kits & fix these old rifles? YES WE DO! (Click here to purchase one) You may wonder how it works. You can think of having three basic options: Option 1: Buy a Remington kit and Do It Yourself (DIY). The is your least expensive option. To decide if you want to pay us to convert the bolt, have your gunsmith do it, or try it yourself, I recommend you study the online installation instructions and see the tools and skills needed. The most common thing people mess up up during the conversion process and need to replace is the firing pin, and a new one costs more than our install service. So I always recommend you purchase our install service and send me the bolt (I'm getting ahead of myself as that is option two below). Note, there is not an "Option 1" for a Ruger (the Ruger's conversion is too complicated). Option 2: Send us the bolt and pay us to convert it You can purchase the kit for a Remington and add installation, or purchase an installed kit for the Ruger. Then ship us the bolt. Let's call this option 2. It's in the middle of cost, but very simple as you just have to ship us the bolt, we convert it and send it back. While the costs differ, this option is basically the same between the Remington 700 ML and the Ruger 77/50. When it comes to option 2: you send us the bolt, it's converted, then shipped back with the new breech plug/vent liner and other small tools. Again, with the Ruger 77/50, there is no option one. Option 3: Buy a new bolt we build from scratch Option 3 is the most expensive option: buy an already converted bolt with a breech plug. I only recommend option 3 when people hunt in Idaho, or Oregon (for some hunts in those states they have to use exposed caps, but have other hunts where they can seal the breech and use 209's). This option is also viable for folks who have rifles that are missing bolts. We used to build bolts for both rifles, but right now we only offer this for the Ruger 77/50. If you have a bolt for your rifle, even if its frozen or broken, our recommendation is for you to purchase a kit with our conversion service (Option 2) and send it to me. I'll look it over and let you know what, if anything, is needed to convert it. I have a pretty good track record on salvaging frozen/broken bolts and keeping it cheaper than buying an entire new bolt. If you still have questions, you probably can find an answer in our FAQ, or within the archives along the right side of these Badger's Den posts. Please take a look at the FAQ (Frequently Asked Questions) before you call or use the contact form: the answers you want are probably there (and you will probably get them quicker via the FAQ. If you aren't finding what you need, you can call us (our number is on the bottom of every web page: 989 795 2526) or use the Contact page by clicking here (or under "More" in the banner above) to initiate a conversation. We'll call you back or reply with an email. Remember you can always add what you want to your chart, and complete an online check out. Hope this helps! Welcome to the Badger's Den. This is where we discuss Badger Ridge's solutions to problems, aka Our Products.

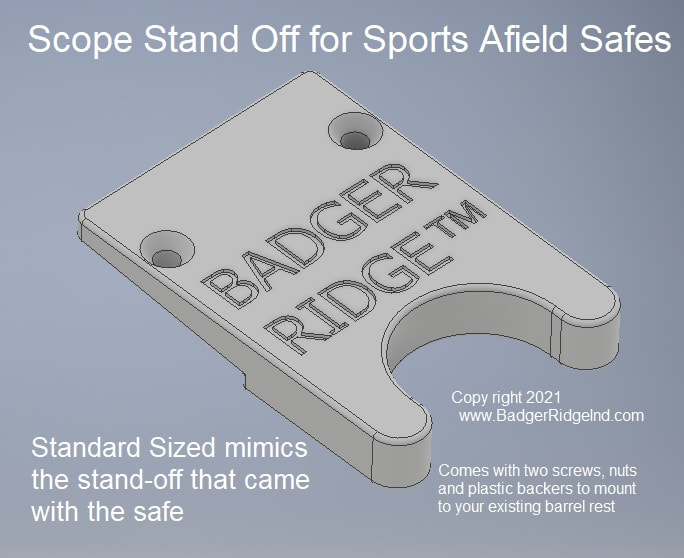

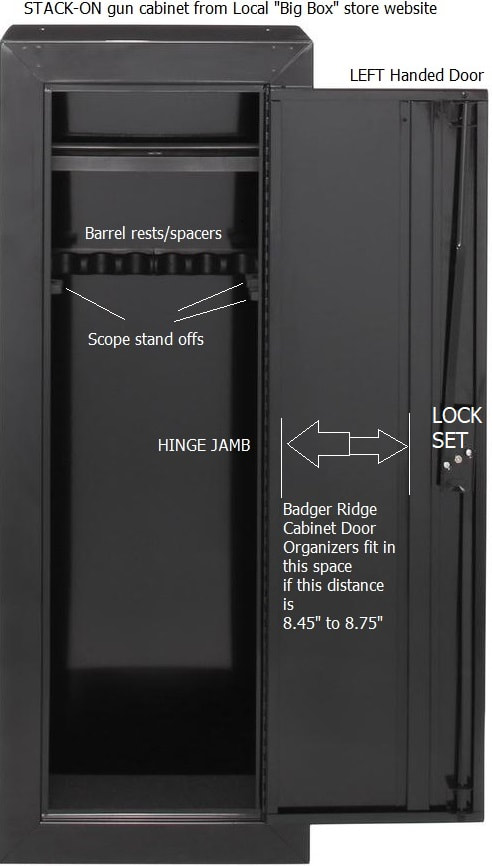

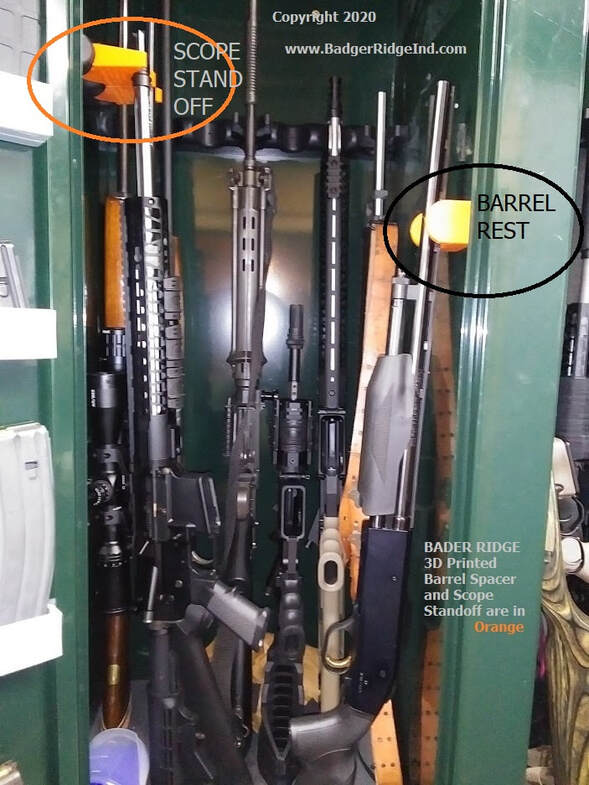

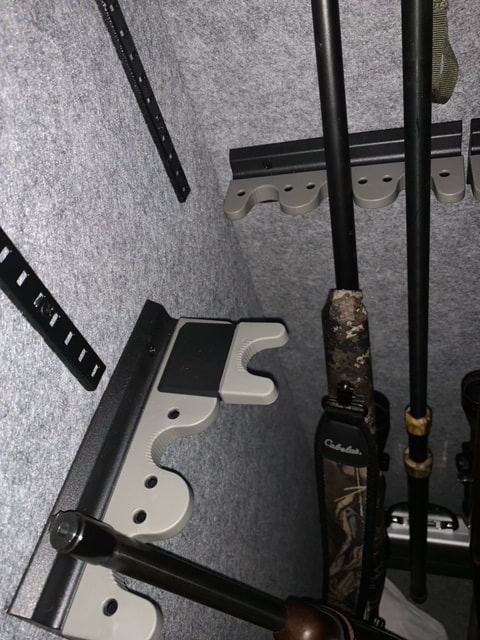

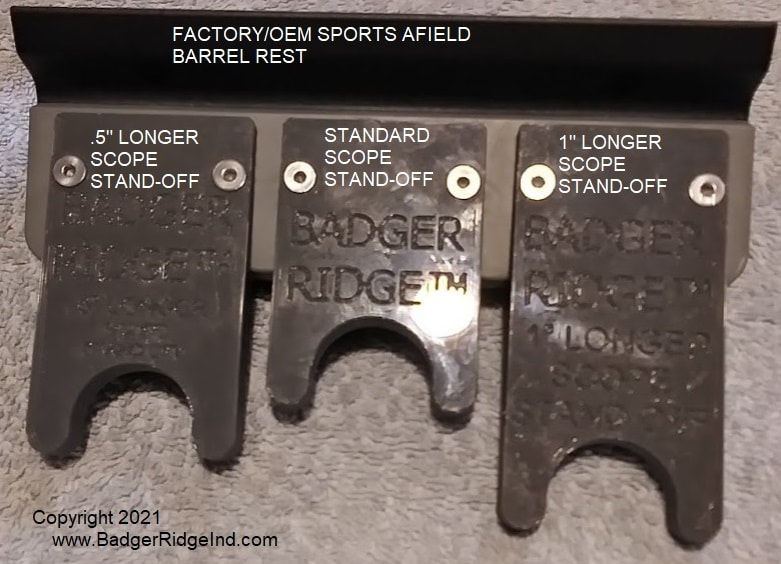

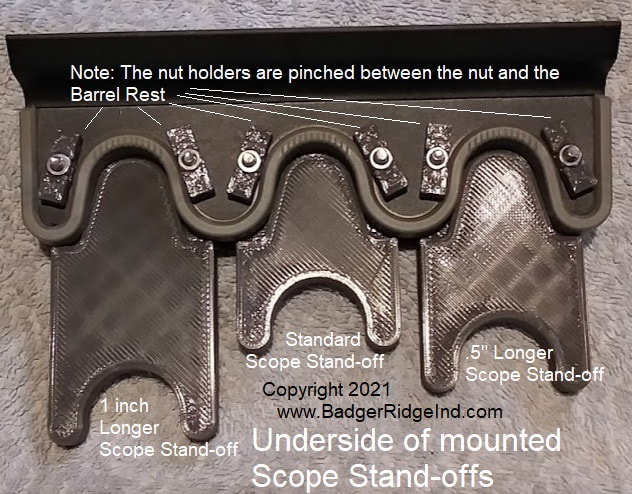

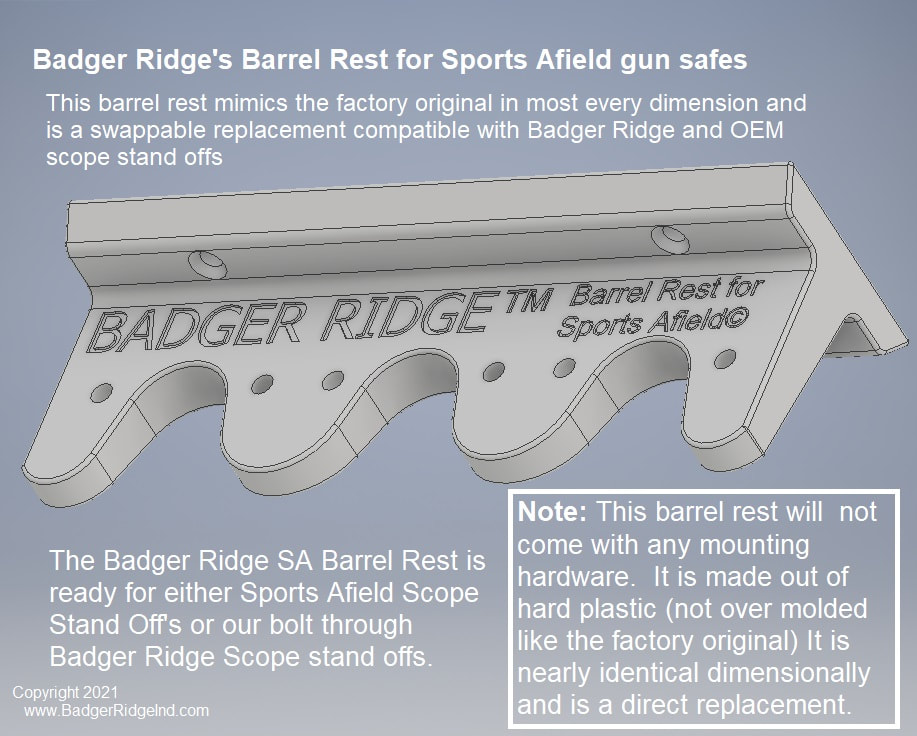

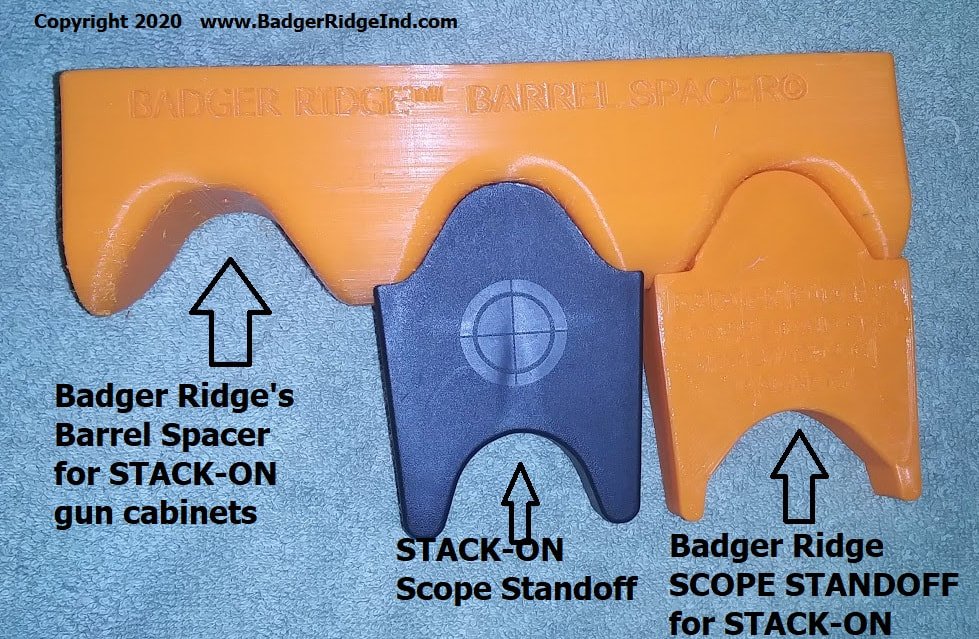

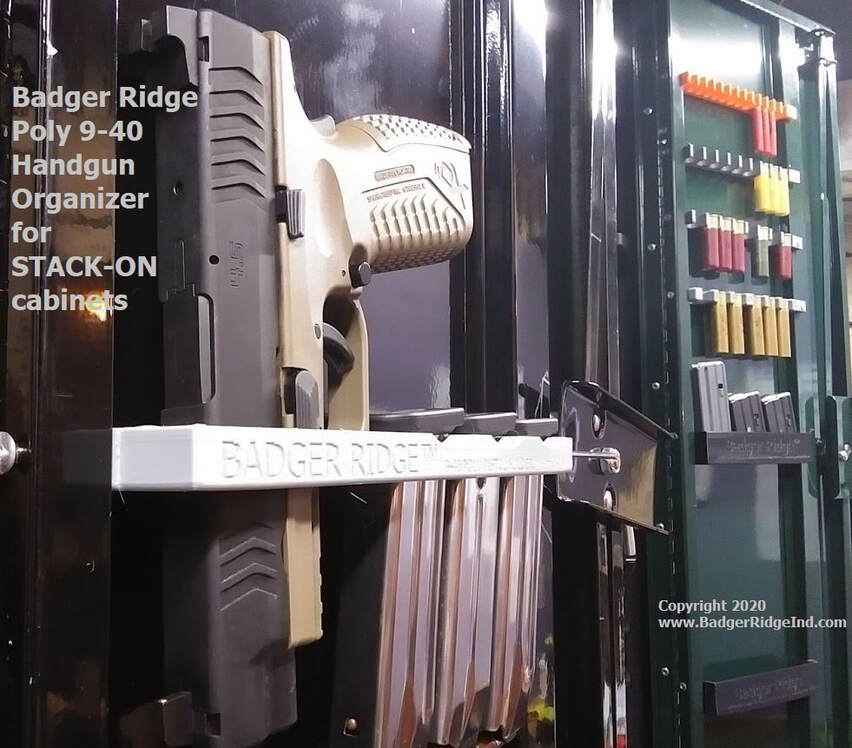

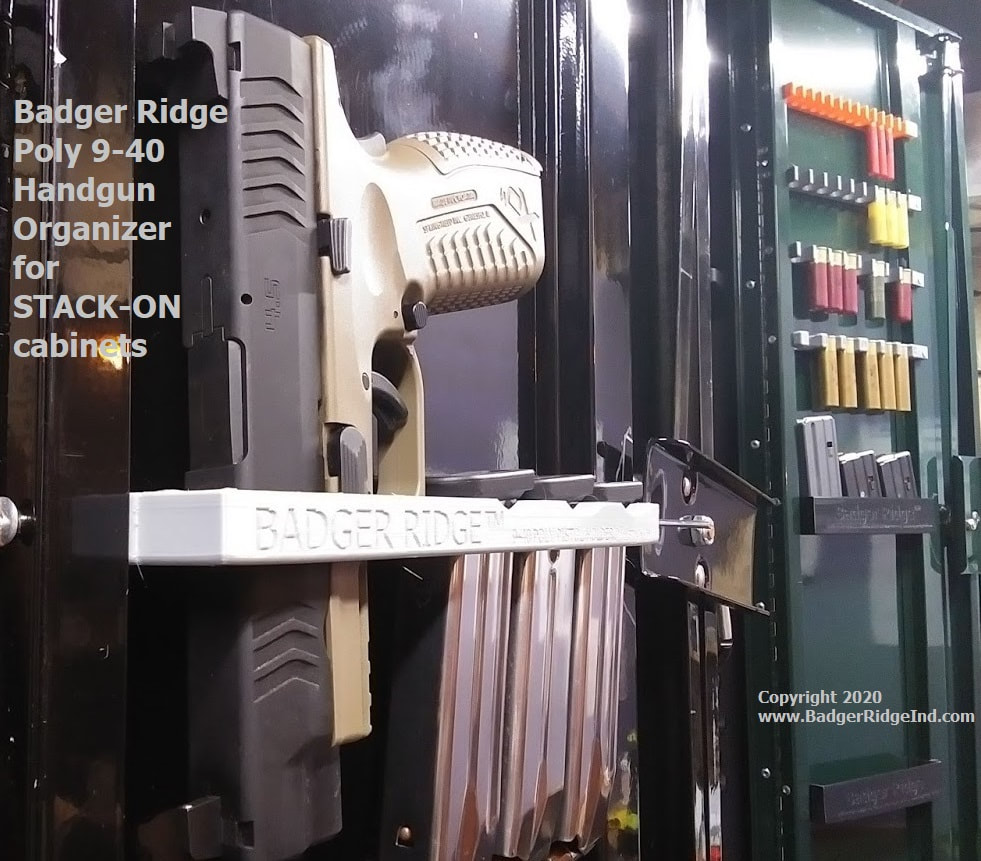

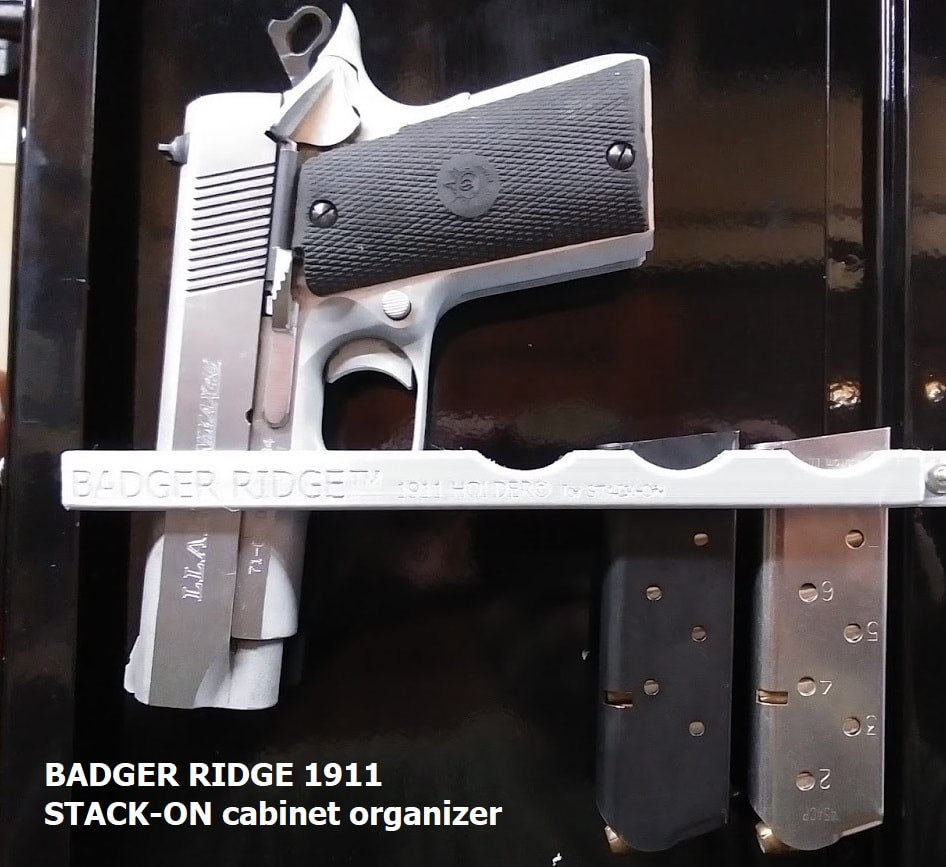

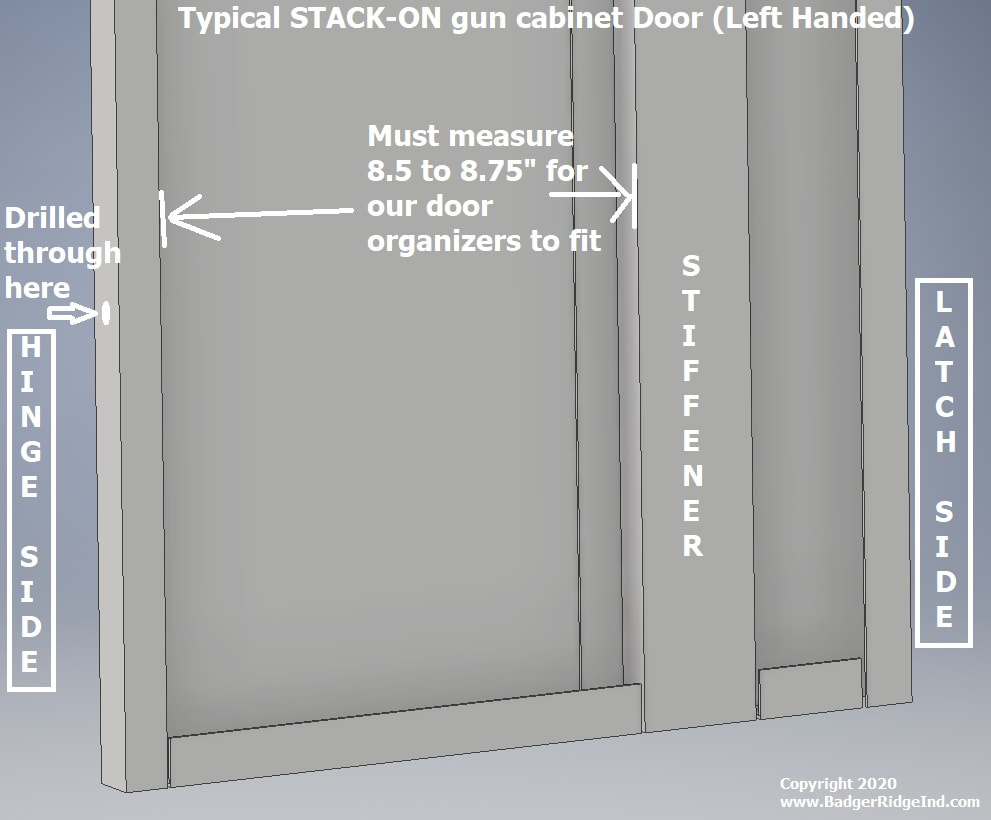

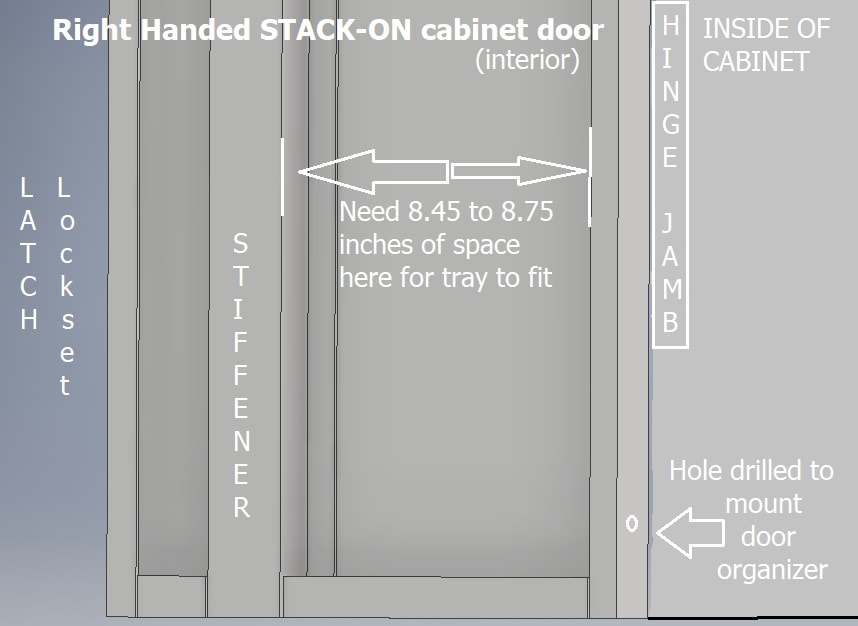

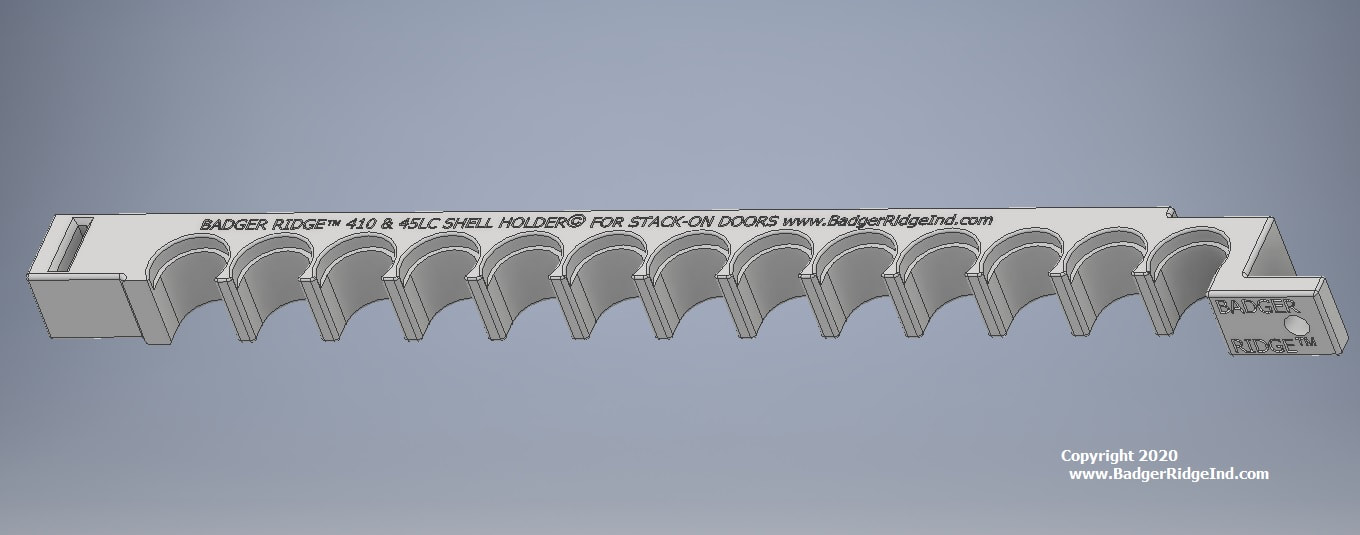

We built up this website through many years of trying different things out. Solving problems one at a time in my hobbies (hunting, shooting, HAM radio, flying, etc), I frequently had to develop something unique, or buy something obscure. So we've made it our mission to simplify those things and bring them forward to the masses. Some folks are amazed when they find out we have unique tools and products to solve their issues with their old muzzle loaders, or with the solvent trap they are trying to build.... or with that STACK-ON cabinet that needs more scope stand-offs, just won't hold that SBR or youth model right, and wastes so much space in the door. If an internet search brought you here, but you don't immediately see what you were looking for, please use the menus on the top and sides to continue your search. We update this blog often (so what the search engine sent you here for is probably only one click away). But for this installment, I think I need to rant a little about something I did myself. I had to raise our shipping fees. Well really, I raised the minimum purchase to get free shipping to over $100... which effectively raises the fee's our customers pay to ship stuff. It seems like rising costs of everything are the sign of the times. When I was in college I took a class called "Economics." In that class they called this phenomenon "Inflation", but now-a-days the news and the President seem to call it "COVID". Not sure where my education got off course. Let me get a little more personal: I had COVID, that was a rough week (not only for me, but for my dear wife who was fulfilling orders and caring for me and our daughter... also sick with COVID). But then about 4 months later I got a series of shots to prevent COVID. My mother-in-law and the news assured me that this shot would fix everything. But now I guess it's only a shot that reduces the risk of hospitalization from getting COVID. Oh and 1st class mail seems to randomly run slower due to COVID. Personally, I have family & friends that died due to COVID. And I mean real COVID, not the died in a car crash and tested positive post mortem stuff. I sadly lost a beloved aunt and uncle after stays in the ICU after getting COVID. So I'm not making light of this; I'm concerned the true crisis is being exploited for political control. I'm seeing costs and prices rise and that's called COVID too? And isn't Inflation like I learned in school? I also learned that inflation was caused by an "increase in the money supply," but I'm told that creating more $ out of thin air is safe & good for us too (by the Federal Reserve, the news, and others in DC). So, I'm confused and feel that if I continue that this post might ramble a bit or hurt someone's feelings. And all of those are bad for business. Anyways: We are a small, veteran owned, family run business. You and your purchase mean a lot to us. I've been writing this blog for many years now; trying to help folks and promote Our Products. If you are interested in our solutions, or have an idea for us, please register (so we can send you emails when we release new products), and contact us (either by phone or writing a contact form). We are always developing something, and looking for new ideas and products. If an internet search engine brought you here offering a solution to a problem, please keep clicking around our site until you find it. Just understand that we've reviewed our numbers and unfortunately have to raise the bar for getting free shipping. Though we are confident our flat rate policy still keeps costs down and predictable. Edited and updated Dec 2021.  Badger Ridge's Scope Stand-off for Sports Afield Safes (available in 3 lengths) Badger Ridge's Scope Stand-off for Sports Afield Safes (available in 3 lengths) Welcome to the Badger's Den. This is where we discuss Badger Ridge's solutions to problems, aka Our Products. We built up this website through many years of trying different things out. Solving problems one at a time in my hobbies (hunting, shooting, HAM radio, flying, etc), I frequently had to develop something unique, or buy something obscure. So we've made it our mission to simplify those things and bring them forward to the masses. Some folks are amazed when they find out we have unique tools and products to solve their issues with their old muzzle loaders, or with the solvent trap they are trying to build.... or with that STACK-ON cabinet that needs more scope stand-offs, just won't hold that SBR or youth model right, and wastes so much space in the door. If an internet search brought you here, but you don't immediately see what you were looking for, please use the menus on the top and sides to continue your search. We update this blog often (so what the search engine sent you here for is probably only one click away). We are a small, veteran owned, family run business. You and your purchase mean a lot to us. I've been writing this blog for many years now; trying to help folks and promote our products. If you are interested in our solutions, or have an idea for us, please register (so we can send emails out when we release new products), and contact us (either by phone or writing a contact form). We are always developing something, and looking for new ideas and products. After being contacted by Justin H of Nebraska, we'd developed and launched a new product line: Scope Stand-offs & Barrel Rests for Sports Afield safes: After working with Justin via texts and emails for a few weeks, he said I could share his messages and texts with you to help you see how things went. I of course, have edited these for clarity, to keep it pertinent, and protect his privacy. FROM OUR CONTACT PAGE: You've just received a new submission to your Contact Form. Name: Justin H, Nebraska USA Question or Comment I am looking for stand offs for Sports Afield safes (or ones that will work for my safe). I have pictures of the barrel rests and the extensions for scoped rifles, but your system will not let me paste them here. Any help would be greatly appreciated. Please, let me know how to send you the pictures, or if the stand-offs you make for other safe systems will fit. I’ve called Sports Afield: they don’t sell accessories, nor can they tell me where to get more. My safe only came with 2 scope stand-offs. I want more, and it seems the stand-off fairy just puts them in the safe: they have no clue how to direct me to getting more. I'm confused as to how a company has parts made for their safes and is not be able to direct a consumer where to get more accessories. Hoping maybe you can help me out. Thanks! Justin H My reply (via email... if you want our email address fill out a Contact form and we'll email you back... typically within 24-48 hours... but we don't post our email address openly in order to combat spam) --------- Justin, Thanks for your interest in our services and products! You can send pictures here to this email address (or text them to my cell phone below). I'll take a look at what you have if you get them to me. Yours, Tom Main/Voice: 989 795 2526 Cell: (removed... again use the Contact form and I'll gladly provide it to those who need it) To: BadgerRidgeIndustries From: Justin H Tom, Here's some pics of what came with the safe: Let me know if these pics will work. Also, on top of needing more stand-offs, these Scope Stand off's seem a little to short for my rifles with bigger scopes on them. Can you make some of them longer for those rifles? Yours, Justin