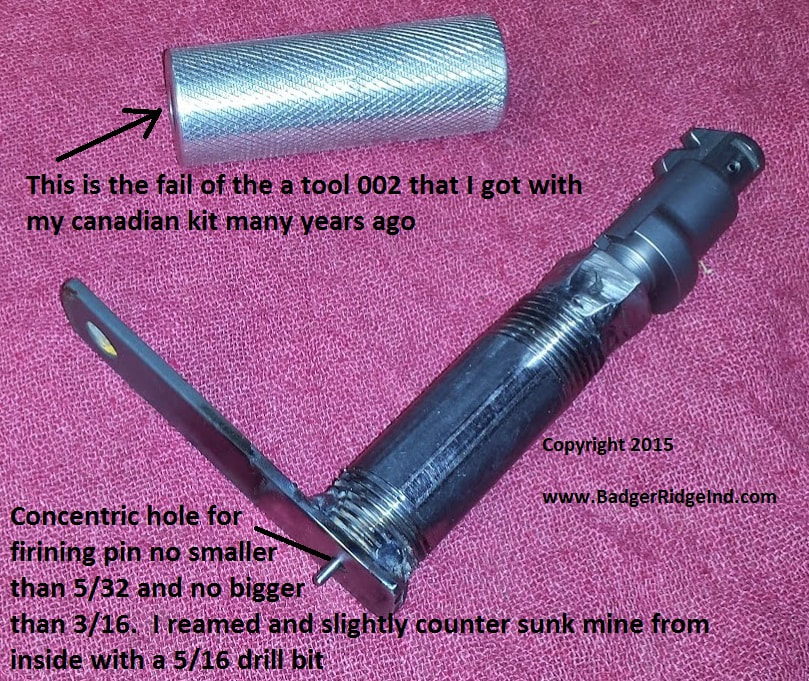

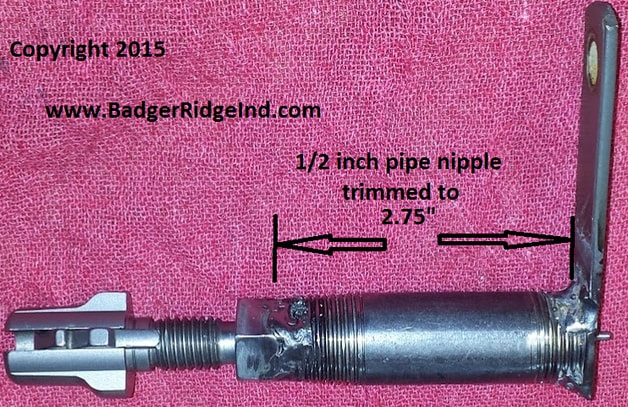

Examples of homemade "tool 002" used to disassemble firing pin from Remington 700 ML/MLS bolts

Fred's original installation documents were copies of some hand drawn depictions of how to install the kit. There was some text and a hand written note to call him if you needed help. The illustration that showed the firing pin being removed labeled what I refer to as tool (7) as "Tool 002" I'm going to keep that nomenclature here to honor the creator of the kit.

The Bolt Tool I made just for 700 ML rifles (aka Tool 002)

My favorite firing pin tool above

My favorite firing pin tool above

My local hardware store didn't have 7/16 ID pipe/tubing (like you will see Fishhawk made below). So I got a 3" long 1/2" black pipe nipple and a 1/2"x13TPI nut. I ground both threaded ends of the nipple down until it was 2 3/4" long. This gave me more metal to weld to and made the tool the right length. I blew out all the crud from grinding and welded the nut to the nipple, and then took a piece of flat stock and drilled at 5/32 hole along its center-line. I then welded that to the other end of the nipple so that the 5/32 hole would be concentric to the nut. I ran a 5/16 drill bit through to de-bur and slightly dimple the hole from the inside to better guide the firing pin out when threading onto the firing pin assembly. I then ran a 1/2"x13TPI tap through to clean out the spatter and flash that had gotten on the threads before I ran it up a bolt.

This is my favorite version for working on 700 ML rifles

This is my favorite version for working on 700 ML rifles

The one Fishhawk made

The bolt tool I made that works on any Remington firing pin assembly

Later after working on these for a while, and having to work on some other Remington 700 bolts (both long and short action) I made up a tool that will work with any Remington 700 (ML, Short Action, Long Action), along with Model 7's, 40X's and others:

Materials:

-2 - 1/2x13 nuts

-2 Pieces of 1/2 angle, cut to 6" or 7" (7 makes it easier on the long action firing pins, but 6" is workable)

-4" or 4 1/2" all thread 1/2x13 bolts. (4 1/2" is needed to do ML bolts in a 7" jig). Bore out 1/4" about 1 3/4")

You can buy similar tools on line for $30.00 plus shipping. But this seems stronger and better to me.

Also I'm not a welder, all our real welding, like bolt handles is done by my brother, a professional, certified, journeyman welder.

-2 - 1/2x13 nuts

-2 Pieces of 1/2 angle, cut to 6" or 7" (7 makes it easier on the long action firing pins, but 6" is workable)

-4" or 4 1/2" all thread 1/2x13 bolts. (4 1/2" is needed to do ML bolts in a 7" jig). Bore out 1/4" about 1 3/4")

You can buy similar tools on line for $30.00 plus shipping. But this seems stronger and better to me.

Also I'm not a welder, all our real welding, like bolt handles is done by my brother, a professional, certified, journeyman welder.

In vice ready to drive out pin

In vice ready to drive out pin

Al R, improvised the tool below when circumstances meant he couldn't weld:

The B/M is:

(1) short piece of angle or barstock

(2) #10 ViseGrip pliers

(2) ½-13 nuts (while square is best, heavy hex would be ok, and standard nuts would work)

(1) ½-13 hex head cap screw, drilled to accept firing pin

The B/M is:

(1) short piece of angle or barstock

(2) #10 ViseGrip pliers

(2) ½-13 nuts (while square is best, heavy hex would be ok, and standard nuts would work)

(1) ½-13 hex head cap screw, drilled to accept firing pin