Frequently Asked Questions (FAQ)

Q: Can I do business with you through the mail? What is your phone number? Can I order over the phone? What is your address? Can I just send you a check?

A: "We understand some just don't trust the internet, credit cards, websites, etc. If you want to get in touch with us we only ask that you use the "Contact" page (look under "More") to submit your questions and inquiries, or call us at the phone number at the bottom of each web page (9AM -8PM Eastern Monday - Friday, we may answer outside those hours, and you can always use our automated information system). If you leave a message: Be sure give us a telephone number or email address or it will be hard to get with you!!!

I promise you, if you submit a 'contact us' form with your contact info, or leave me a voice mail, we usually reply with in 48 hrs (often within a few hours... depending on if we are on vacation as listed in the TERMS of Use).

If you want to do business through the mail; we can oblige. For non-website sales, WE ONLY ACCEPT POSTAL MONEY ORDERS. Please browse the website like it is a catalog, write down what you want with the amounts and totals. If your order is under $100, add $7.49 for shipping. If you are in Michigan remember to add 6% sales tax to the subtotal (and shipping is taxed)! Make Postal Money Orders payable to Badger Ridge LLC, and mail them to PO BOX 223, Fostoria MI 48435

You can also initiate a conversation with us through the 'contact' form under the "more" tab above, or call us at the phone number at the bottom of every page of our website.

While we are on Facebook we don't check the messages there all that often. You will be best served by calling us, or using the contact form.

We are not set up to take credit cards over the phone (nor take orders): please check out on line if you wish to pay via credit card. We used to take PayPal until they went overboard with the politics and policing of commerce: Thus we don't accept PayPal anymore. Don't ask about it, you may not like what we have to say about the PayPal cartel.

If you checkout on-line: your invoice will be sent to you via email and will have our physical address; so be sure to put an email address in the online check out form when purchasing installation!"

I promise you, if you submit a 'contact us' form with your contact info, or leave me a voice mail, we usually reply with in 48 hrs (often within a few hours... depending on if we are on vacation as listed in the TERMS of Use).

If you want to do business through the mail; we can oblige. For non-website sales, WE ONLY ACCEPT POSTAL MONEY ORDERS. Please browse the website like it is a catalog, write down what you want with the amounts and totals. If your order is under $100, add $7.49 for shipping. If you are in Michigan remember to add 6% sales tax to the subtotal (and shipping is taxed)! Make Postal Money Orders payable to Badger Ridge LLC, and mail them to PO BOX 223, Fostoria MI 48435

You can also initiate a conversation with us through the 'contact' form under the "more" tab above, or call us at the phone number at the bottom of every page of our website.

While we are on Facebook we don't check the messages there all that often. You will be best served by calling us, or using the contact form.

We are not set up to take credit cards over the phone (nor take orders): please check out on line if you wish to pay via credit card. We used to take PayPal until they went overboard with the politics and policing of commerce: Thus we don't accept PayPal anymore. Don't ask about it, you may not like what we have to say about the PayPal cartel.

If you checkout on-line: your invoice will be sent to you via email and will have our physical address; so be sure to put an email address in the online check out form when purchasing installation!"

Questions about Freeze Plugs

Q: How do your freeze plugs fit into my tube?

A: "For D cell tubes there used to be two basic choices of freeze plugs: Dorman (made in China) and Sealed Power (Made in USA). Dorman plugs typically have an over-sized max outside diameter for most D Cell tubes and frequently must be pounded into the tube. They are thicker and generally made of a poorer quality steel. You may find videos of people using 1" sockets and extensions on YouTube and having a super hard time getting their Dorman plugs into the tube. Badger Ridge does not sell nor service Dorman plugs.

However we do sell Sealed Power (or versions that emulate those dimensions) as they are usually just a few thousandths smaller than Dorman and typically slip right into a properly made solvent trap tube. Our formed and unformed plugs (D Cell) measure a max outer diameter of about 1.350". Our stainless plugs more or less emulate the dimensions of the Sealed Power 381-3179 D cell. Note I said properly made solvent trap tube: most aluminum flashlight D cell tubes are still tight even on Sealed Power plugs! The trouble is Sealed Power shut down its domestic production. We are selling our existing stock and currently selling and stocking non-China options for the same or with similar fit.

The manufacturer of the tube sets the tube's inside diameter. As the degree of slip fit is due to the combination of the tube's inside diameter and the plug's outside diameter, we cannot comment as to how our plugs will fit any particular tube. Again: most aluminum D cell flash light tubes are very snug on freeze plugs.

I can say that the D cell Sealed Power and our Stainless D cells are a wonderful slip fit in my SD Tactical Ti tubes. It is normal to have to pound D cell plugs into aluminum flash light tubes (unless you reduce the outside diameter of the plug). YouTube has lots of good and bad ideas on how to reduce plugs' outside diameters.

For C Cell plugs, please take the time and read the full description. Our forming die does expand the skirt of the plug slightly, and our formed C cells fit well in both of my C cell mag-lites. The max diameter of the skirt tends to vary from 1.029" to 1.035", with most falling around 1.032". C cell aluminum flash lights tend to be a little loose on C cell plugs (which is why our die expands the skirt a little). Also our space pipe is a bit undersized: that is typically tuned by wrapping the ends with electrical tape. Typically the undersized plugs is a non issue once the stack is secured by the end caps.

All our B cell plugs, and spacer pipe have been a great fit in my SD tactical B cell tubes.

If you are not satisfied with the fit of our product, you may return it (un-modified) for a full refund per the terms of the original sale. (Return postage paid by the purchaser, and we'll keep some money for shipping and handling expenses)"

A: "For D cell tubes there used to be two basic choices of freeze plugs: Dorman (made in China) and Sealed Power (Made in USA). Dorman plugs typically have an over-sized max outside diameter for most D Cell tubes and frequently must be pounded into the tube. They are thicker and generally made of a poorer quality steel. You may find videos of people using 1" sockets and extensions on YouTube and having a super hard time getting their Dorman plugs into the tube. Badger Ridge does not sell nor service Dorman plugs.

However we do sell Sealed Power (or versions that emulate those dimensions) as they are usually just a few thousandths smaller than Dorman and typically slip right into a properly made solvent trap tube. Our formed and unformed plugs (D Cell) measure a max outer diameter of about 1.350". Our stainless plugs more or less emulate the dimensions of the Sealed Power 381-3179 D cell. Note I said properly made solvent trap tube: most aluminum flashlight D cell tubes are still tight even on Sealed Power plugs! The trouble is Sealed Power shut down its domestic production. We are selling our existing stock and currently selling and stocking non-China options for the same or with similar fit.

The manufacturer of the tube sets the tube's inside diameter. As the degree of slip fit is due to the combination of the tube's inside diameter and the plug's outside diameter, we cannot comment as to how our plugs will fit any particular tube. Again: most aluminum D cell flash light tubes are very snug on freeze plugs.

I can say that the D cell Sealed Power and our Stainless D cells are a wonderful slip fit in my SD Tactical Ti tubes. It is normal to have to pound D cell plugs into aluminum flash light tubes (unless you reduce the outside diameter of the plug). YouTube has lots of good and bad ideas on how to reduce plugs' outside diameters.

For C Cell plugs, please take the time and read the full description. Our forming die does expand the skirt of the plug slightly, and our formed C cells fit well in both of my C cell mag-lites. The max diameter of the skirt tends to vary from 1.029" to 1.035", with most falling around 1.032". C cell aluminum flash lights tend to be a little loose on C cell plugs (which is why our die expands the skirt a little). Also our space pipe is a bit undersized: that is typically tuned by wrapping the ends with electrical tape. Typically the undersized plugs is a non issue once the stack is secured by the end caps.

All our B cell plugs, and spacer pipe have been a great fit in my SD tactical B cell tubes.

If you are not satisfied with the fit of our product, you may return it (un-modified) for a full refund per the terms of the original sale. (Return postage paid by the purchaser, and we'll keep some money for shipping and handling expenses)"

Q: What mounts/tubes/end caps do you recommend?

Our plugs are standard industry size. (except that the C cell plugs skirts are slightly expanded). There are a myriad of tubes out there. So long as the tube's ID (Inside Diameter) is larger than the plugs OD (Outside Diameter) our plugs will fit. How loose or snug depends on the difference of the two diameters. (See Q: How do your freeze plugs fit into my tube? above).

We sell spacer pipe that goes inside with the plugs, but we don't sell the mounts, end-caps, nor the outer tubes.

That said, I've always used, and been very please with SD Tactical's products. Our plugs have been great slip fits in their tubes, and on that rare occasion they were a tad small on their ID, SD stood behind their product and replaced it. I tend to buy their Titanium Tubes, and mostly titanium mounts and end caps. I like the lock up of their mounts to their variety of flash suppressors, muzzle breaks, they offer. If you buy SD mounts it will work with any SD pattern barrel device. Ie: the SD threaded end cap will fit any SD pattern muzzle device (flash hider, break, etc). They do sell muzzle devices for other mounting systems too.

Also they sell their own inertial decouplers for pistols that require them such as 1911's, Glocks, XD's, and most polymer pistols. These are B cell sized, or "Option B" as they call it. Same thread as Liberty and other decouplers. Their B tubes will thread on this standard decoupler size/thread and our B cell plugs typically float right down the tube.

Some folks get confused about the terminology: The mount to the flash suppressor/break may be listed as an end cap that has an SD thread... etc. Their tubes may be listed as barrel shrouds, or mag-lite extenders. Take your time and read the full lists, browse their site, and understand what you are purchasing.

https://sdtacticalarms.com/

We sell spacer pipe that goes inside with the plugs, but we don't sell the mounts, end-caps, nor the outer tubes.

That said, I've always used, and been very please with SD Tactical's products. Our plugs have been great slip fits in their tubes, and on that rare occasion they were a tad small on their ID, SD stood behind their product and replaced it. I tend to buy their Titanium Tubes, and mostly titanium mounts and end caps. I like the lock up of their mounts to their variety of flash suppressors, muzzle breaks, they offer. If you buy SD mounts it will work with any SD pattern barrel device. Ie: the SD threaded end cap will fit any SD pattern muzzle device (flash hider, break, etc). They do sell muzzle devices for other mounting systems too.

Also they sell their own inertial decouplers for pistols that require them such as 1911's, Glocks, XD's, and most polymer pistols. These are B cell sized, or "Option B" as they call it. Same thread as Liberty and other decouplers. Their B tubes will thread on this standard decoupler size/thread and our B cell plugs typically float right down the tube.

Some folks get confused about the terminology: The mount to the flash suppressor/break may be listed as an end cap that has an SD thread... etc. Their tubes may be listed as barrel shrouds, or mag-lite extenders. Take your time and read the full lists, browse their site, and understand what you are purchasing.

https://sdtacticalarms.com/

Q: What tool for drilling holes in freeze plugs? Or can you drill them for me?

A: "We sell components for gun cleaning equipment only. Remember that drilling holes in freeze plugs could constitute an act that is regulated by, or a felony according to the NFA. We are not a lawyers, so we suggest you seek proper counsel, consult the BATF, and be sure you have an approved Form 1 from the BATF before even considering modifying these items. We will not modify our plugs in any way, including drilling holes... for anyone. Don't ask us to make and exception: we won't be nice in our response.

Not all vendors take the time to center mark their plugs, and some just make a barely perceptible mark. Badger Ridge's are centered with a spinning drill bit, and we also accept returns of un-modified products should a customer not be satisfied. Check out all the terms others put on their sales, especially Ebay, before you buy. Buyer beware!

A special tool is not needed to drill centered holes in the plugs we sell. When pressed, a spinning bit is put down the hole in the center of the jig and removes just a little metal to 'center mark' them. This mark is concentric to the outer rim of the plug, not the flat of the cone. As our forming dies wear the tip makes an inconsequential slightly irregular flat bottom to the cone, so its important to note the bit and thus the center mark are concentric to the outer rim of the plug, not the bottom of the cone.

Anyways, if held with a pair of slip joint pliers and a drill bit lined up with the centered mark, centered holes are straight forward (A drill press near its highest speed with a sharp 3/16 bit should work best).

We've heard of people using another unformed plug in a SD Tactical centering tool and lining it up centered on top of the formed plug with a vice or vice grips. Then a hole is drilled via the SD jig. Others have had to do that when they bought plugs offered by other vendors (that don’t center them). We don't think you'll need the SD tool with our plugs. FYI, The SD Tactical tool uses an 1/8" bit.

Getting centered holes: When you start with stamped parts, then run them through a die and use a spinning bit to mark the center, the tolerances all stack (plugs aren't perfect, dies have clearances built in between the components and the spinning drill bit, etc). So nothing is exact. But I (and many many happy customers) found our plugs to be well within usable tolerances. Factor in that the nose of the die wears at the tip... so the bottom of the cone is imperfect and makes an optical illusion: they are probably more centered than you believe! With stainless typically you can turn them over and look at the pin prick of metal made by the tip of the bit and rotate the plug around it like its an axis... you'll be surprised at how much "more" centered it appears. You can also do the same with the drill mark: use it as an axis, rotate the outer rim around and it will look really good but the cone will appear to wobble: the cone isn't perfect, and the rim will wobble because it isn't perfect either, and the rim is tapered, all of which compound to make an optical illusion. Again use the mark as the axis of rotation and look at everything when you rotate it.

But even if you don't like what you see, and your application requires you to put a hole in and enlarge it, typically folks use long drill bits and jigs to put the last enlargement through all the plugs in the tube at the same time, and drill rod to check for a wide (over bore) straight path through that final enlargement: it makes up for all variations in the drilling process.

For those still on the not perfect centered path here: Like all things in manufacturing there are tolerances. How centered is centered? How do you measure it? What is good enough? The answer to this gets into GD&T theory, and what one uses as clearances in their end use (aka over bore), and their techniques when drilling and enlarging holes. You need a GD&T definition of what center tolerances are, an optical comparator/CMM machine to measure this properly....

Bottom line: The part is stamped, its rim has a few thou taper to it, and the OD tends to wobble a few thou before we even pressed it into a cone, and the drill bit has to clear the centering hole in the die... in the end we produce a good part that works well if the user does their part.

If you are not satisfied with the fit of our product, you may return it (un-modified) for a full refund per the terms of the original sale. (Return postage paid by the purchaser, and we'll keep some money for shipping and handling expenses)"

AGAIN, WE ONLY SELL COMPONENTS FOR CLEANING PRODUCTS AND CANNOT MAKE ANY RECOMMENDATIONS ON OTHER USES OF OUR PRODUCTS, NOR WILL WE MODIFY THEM."

A: "We sell components for gun cleaning equipment only. Remember that drilling holes in freeze plugs could constitute an act that is regulated by, or a felony according to the NFA. We are not a lawyers, so we suggest you seek proper counsel, consult the BATF, and be sure you have an approved Form 1 from the BATF before even considering modifying these items. We will not modify our plugs in any way, including drilling holes... for anyone. Don't ask us to make and exception: we won't be nice in our response.

Not all vendors take the time to center mark their plugs, and some just make a barely perceptible mark. Badger Ridge's are centered with a spinning drill bit, and we also accept returns of un-modified products should a customer not be satisfied. Check out all the terms others put on their sales, especially Ebay, before you buy. Buyer beware!

A special tool is not needed to drill centered holes in the plugs we sell. When pressed, a spinning bit is put down the hole in the center of the jig and removes just a little metal to 'center mark' them. This mark is concentric to the outer rim of the plug, not the flat of the cone. As our forming dies wear the tip makes an inconsequential slightly irregular flat bottom to the cone, so its important to note the bit and thus the center mark are concentric to the outer rim of the plug, not the bottom of the cone.

Anyways, if held with a pair of slip joint pliers and a drill bit lined up with the centered mark, centered holes are straight forward (A drill press near its highest speed with a sharp 3/16 bit should work best).

We've heard of people using another unformed plug in a SD Tactical centering tool and lining it up centered on top of the formed plug with a vice or vice grips. Then a hole is drilled via the SD jig. Others have had to do that when they bought plugs offered by other vendors (that don’t center them). We don't think you'll need the SD tool with our plugs. FYI, The SD Tactical tool uses an 1/8" bit.

Getting centered holes: When you start with stamped parts, then run them through a die and use a spinning bit to mark the center, the tolerances all stack (plugs aren't perfect, dies have clearances built in between the components and the spinning drill bit, etc). So nothing is exact. But I (and many many happy customers) found our plugs to be well within usable tolerances. Factor in that the nose of the die wears at the tip... so the bottom of the cone is imperfect and makes an optical illusion: they are probably more centered than you believe! With stainless typically you can turn them over and look at the pin prick of metal made by the tip of the bit and rotate the plug around it like its an axis... you'll be surprised at how much "more" centered it appears. You can also do the same with the drill mark: use it as an axis, rotate the outer rim around and it will look really good but the cone will appear to wobble: the cone isn't perfect, and the rim will wobble because it isn't perfect either, and the rim is tapered, all of which compound to make an optical illusion. Again use the mark as the axis of rotation and look at everything when you rotate it.

But even if you don't like what you see, and your application requires you to put a hole in and enlarge it, typically folks use long drill bits and jigs to put the last enlargement through all the plugs in the tube at the same time, and drill rod to check for a wide (over bore) straight path through that final enlargement: it makes up for all variations in the drilling process.

For those still on the not perfect centered path here: Like all things in manufacturing there are tolerances. How centered is centered? How do you measure it? What is good enough? The answer to this gets into GD&T theory, and what one uses as clearances in their end use (aka over bore), and their techniques when drilling and enlarging holes. You need a GD&T definition of what center tolerances are, an optical comparator/CMM machine to measure this properly....

Bottom line: The part is stamped, its rim has a few thou taper to it, and the OD tends to wobble a few thou before we even pressed it into a cone, and the drill bit has to clear the centering hole in the die... in the end we produce a good part that works well if the user does their part.

If you are not satisfied with the fit of our product, you may return it (un-modified) for a full refund per the terms of the original sale. (Return postage paid by the purchaser, and we'll keep some money for shipping and handling expenses)"

AGAIN, WE ONLY SELL COMPONENTS FOR CLEANING PRODUCTS AND CANNOT MAKE ANY RECOMMENDATIONS ON OTHER USES OF OUR PRODUCTS, NOR WILL WE MODIFY THEM."

QUESTIONS ABOUT 209 MUZZLE LOADER CONVERSION PRODUCTS

Q: Do you really sell kits and service old, not in production rifles, like the Remington 700 ML/MLS and the Ruger 77/50?

A: "Yes, we do, and we are still open because you are reading this web page! Buy with confidence!"

Q: I don't want to switch to your awesome 209 sealed breech system. Will you help me fix my 700 ML or Ruger 77/50 with the original leaky set up?

A: We want the best for you, and want to help you. We are convinced the best thing is to dump the leaky system your rifle has installed and use our sealed breach system. If you have to keep the old one running, and are having trouble with misfires, we can strip your bolt totally down, clean it, replace the 700 ML mainspring, and ship it back to you for a fair fee. Click here to read more about our mainspring replacement service. Other wise, we are not interested in supporting a system that is prone to fail. It's just bad business; our 209 kit does so much better. You can read all about why we are confident of that by clicking here. So we don't sell any replacement parts for the original configuration beyond new Remington 700 ML mainsprings. We can build an entire replacement bolt for the old system, but we really only want to do this for those who have converted their original bolt to our 209 system and drew a tag in Idaho or Oregon (the only two states that require leaky percussion caps).

Q: Why do you recommend to not use "muzzleloader" primers in my muzzleloader? Why did the "muzzleloader 209 primer" I tried with Blackhorn209 fail but the standard or magnum 209 primer worked? Why does Western Powders (now Hodgdon aka makers of Blackhorn209) say to use magnum primers, but you say I can use standard primers or magnum primers, but not "inline muzzleloading" 209 primers? Why does the primer say it's non corrosive, but you say I need to clean my muzzleloader soon after shooting because it will corrode? I've got a stainless muzzleloader, do I really need to clean it after shooting?

A: These are all Good questions with seemingly contradictory information.

If you want the short answer, and you have a Remington 700 ML/MLS or a Ruger 77/50, the short answer is: buy our conversion kit, use full powered standard or magnum 209 shotgun primers and pair them with Sabots and Blackhorn209. Clean your muzzleloader thoroughly after shooting.

The short answer also can be summarized as: not all muzzle loader and gun cleaning stuff is compatible with all other muzzle loader and gun cleaning stuff. Read and follow each item's directions. Our kits seal the breech, so they are compatible with any muzzle loader powder, this helps simplify much of the compatibility issues, but not all.

If you want the long answer, please read this blog post: https://www.badgerridgeind.com/the-badgers-den/different-209-primers-and-muzzleloading

If you want the short answer, and you have a Remington 700 ML/MLS or a Ruger 77/50, the short answer is: buy our conversion kit, use full powered standard or magnum 209 shotgun primers and pair them with Sabots and Blackhorn209. Clean your muzzleloader thoroughly after shooting.

The short answer also can be summarized as: not all muzzle loader and gun cleaning stuff is compatible with all other muzzle loader and gun cleaning stuff. Read and follow each item's directions. Our kits seal the breech, so they are compatible with any muzzle loader powder, this helps simplify much of the compatibility issues, but not all.

If you want the long answer, please read this blog post: https://www.badgerridgeind.com/the-badgers-den/different-209-primers-and-muzzleloading

Q: How do I ship my bolt?

A: Assuming you are in the U.S., I think its easiest to take the bolt to the post office. Print your receipt, and bring some newspaper to wrap the bolt in and pad the box. When you go your U.S. Post Office you can get a Priority Flat Rate small box (Priority flat rate comes with tracking and insurance!). MAKE SURE THE PACKAGE IS TAPED UP WELL & THE BOLT IS WRAPPED WITH SOME SORT OF PADDING!!! (yes we've gotten some empty packages with holes in them but no bolts!). Should only cost about $11.00 and they will give you the box! (postage rates keep going up and stuff changes, but its the best I know).

We accept commercial shippers too (UPS, FedEx, DHS, ect) as well, and we are located at a residence if they ask. Please Don't ship FedEx nor UPS to our PO box... if you do, we can fix it, but it will just delay your package.

We accept commercial shippers too (UPS, FedEx, DHS, ect) as well, and we are located at a residence if they ask. Please Don't ship FedEx nor UPS to our PO box... if you do, we can fix it, but it will just delay your package.

Q: I ordered a 209 kit for my Remington 700ML/MLS, now that I have it, I don't want to do the conversion myself. Can you do it for me? What do I need to send you?

A: Yes you can have us install the kit you received onto your bolt.

Please purchase installation (the system will charge you a shipping fee unless you add enough extra items to get over the minimum $ for free shipping).

Then send:

1: The bolt from the rifle

2: And the following items from the kit:

-- firing pin

-- main spring

-- bolt nose

-- small cross pin

-- small drill bit.

You can keep the breech plug, vent liner, hex L wrench, and letter "C" [bigger] drill bit, as they are not needed for installation. If you send the parts we don't need, its not a problem. We’ll just ship them back.

Please purchase installation (the system will charge you a shipping fee unless you add enough extra items to get over the minimum $ for free shipping).

Then send:

1: The bolt from the rifle

2: And the following items from the kit:

-- firing pin

-- main spring

-- bolt nose

-- small cross pin

-- small drill bit.

You can keep the breech plug, vent liner, hex L wrench, and letter "C" [bigger] drill bit, as they are not needed for installation. If you send the parts we don't need, its not a problem. We’ll just ship them back.

Q: I live in a state where I can use sealed breech 209's for part of the season, but we have special hunts where I have to use an exposed percussion cap. Can you help?

A: YES WE CAN! We typically recommend that if you have a 700ML or Ruger 77/50 you completely abandon your old exposed, leaky breech, percussion cap system. But we understand that there are special opportunities in some areas if you hold on to your OEM system. To meet your needs we offer complete 209 converted bolts. FOR NOW WE ONLY OFFER COMPLETE BOLTS FOR THE RUGER... working on returning to producing complete Remington bolts.

But if you don't absolutely have to have the old leaky OEM priming system, its our recommendation that you convert your original bolt. Its much cheaper. If you don't have a legal requirement to use the original leaky system, we see no reason to keep it around!

But if you don't absolutely have to have the old leaky OEM priming system, its our recommendation that you convert your original bolt. Its much cheaper. If you don't have a legal requirement to use the original leaky system, we see no reason to keep it around!

Q: I hunt in Colorado, sabots are not allowed for hunting during muzzle loader season. I want to use your awesome 209 conversion, but you say you recommend sabots with jacketed handgun bullets. What are my options?

A: Short answer is our kit will work great with any projectile. I've found Pyrodex, Triple Se7en, and black powder work best with non sabot projectiles. So use our kit and any muzzle loader safe powder (besides BlackHorn209) for your Colorado hunts with Colorado legal projectiles.

Long answer: I realize not all 50 state have the same rules. And some state’s rules are just plain silly. I wrote a blog post about that in detail.

The main thing to remember here: the powder you chose must be compatible with the projectiles you use.

If you want an even longer answer to why the 'Colorado' recommended recipe is just to use Pyrodex or Triple Se7en there, please read this blog post: https://www.badgerridgeind.com/badgerden/getting-ready-for-colorado-muzzle-loader-season

Just about everywhere else, I recommend sabots because they have been accurate, easy to load, and jacketed hand-gun bullets have always been very effective for me. Whatever powder you chose, the velocities your muzzle loader will produce are essentially the same that good jacketed hand-gun bullets are designed for. They tend to kill quickly and bring home game. Sabots are allowed in most states, so that's what I usually recommend.

Long answer: I realize not all 50 state have the same rules. And some state’s rules are just plain silly. I wrote a blog post about that in detail.

The main thing to remember here: the powder you chose must be compatible with the projectiles you use.

If you want an even longer answer to why the 'Colorado' recommended recipe is just to use Pyrodex or Triple Se7en there, please read this blog post: https://www.badgerridgeind.com/badgerden/getting-ready-for-colorado-muzzle-loader-season

Just about everywhere else, I recommend sabots because they have been accurate, easy to load, and jacketed hand-gun bullets have always been very effective for me. Whatever powder you chose, the velocities your muzzle loader will produce are essentially the same that good jacketed hand-gun bullets are designed for. They tend to kill quickly and bring home game. Sabots are allowed in most states, so that's what I usually recommend.

Q: What primer do you recommend? What powder do you use? What is the best load for the 700 ML?

A: Primer choice depends on powder choice. Our Remington 700 ML and Ruger 77/50 kits are compatible with any black powder or black powder substitute. I love and use Blackhorn209 exclusively (though you pretty well have to use sabots with Blackhorn209). Once I found it I gave all my other black powder substitutes away. I wrote about why I love and exclusively use Blackhorn209 in the Badger's Den.

For a Ruger 77/50 using our 209 conversion: I'd use whatever brand of primers gets a crush fit without any shims. Just a simpler solution over having to shim a primer pocket. If you can get magnum primers to crush, that is the one I'd use as they are better in extreme cold. But standard primers have never failed on me. So for the Ruger kit, just go with a good crush.

For our Remington 700 ML/MLS kit, I used to recommend and use standard CCI 209 shot shell primers (the brass or copper colored ones). However, CCI recently changed their primers to ones that have a silver/grey appearance. I haven't used them much, so I cannot recommend them any more. Remember, just about any standard 209 shot shell primer will work with our 209 conversion systems. Some brands of primers tend to balloon and stick in the bolt nose, especially at lower powder charges. They may require a dry firing to remove (typically Winchester). So you can use whatever one you want, but you may have to tune your breech plug to work with some of them.

If you decide to stay with Black Powder, Pyrodex, Triple Seven, etc, I'd still try standard shot shell primers first. However sometimes (but not always) you may find that full power 209's actually reduce accuracy and have ignition issues with these powders. Typically this is due to them driving the powder charge down the barrel and un-compacting it prior to properly igniting it. Frequently this is with loose fitting projectiles (power belts, minie balls, etc). In this case you may want to try lower power 'black powder' or substitute labeled primers. These other primers may stick in the nose; requiring a dry fire to remove. I wrote about that here for the Remington 700 in the badgers den. Never use low power/black powder/Triple Se7en primers with Black Horn 209!

As for best loads, that's a hard one: I wrote a lengthy article in the Badger's Den about it that you should read in regards to the Remington 700. It must be noted that the Ruger 77/50 is similar but the shorter barrel doesn't allow burning all the powder at higher loads.

For a Ruger 77/50 using our 209 conversion: I'd use whatever brand of primers gets a crush fit without any shims. Just a simpler solution over having to shim a primer pocket. If you can get magnum primers to crush, that is the one I'd use as they are better in extreme cold. But standard primers have never failed on me. So for the Ruger kit, just go with a good crush.

For our Remington 700 ML/MLS kit, I used to recommend and use standard CCI 209 shot shell primers (the brass or copper colored ones). However, CCI recently changed their primers to ones that have a silver/grey appearance. I haven't used them much, so I cannot recommend them any more. Remember, just about any standard 209 shot shell primer will work with our 209 conversion systems. Some brands of primers tend to balloon and stick in the bolt nose, especially at lower powder charges. They may require a dry firing to remove (typically Winchester). So you can use whatever one you want, but you may have to tune your breech plug to work with some of them.

If you decide to stay with Black Powder, Pyrodex, Triple Seven, etc, I'd still try standard shot shell primers first. However sometimes (but not always) you may find that full power 209's actually reduce accuracy and have ignition issues with these powders. Typically this is due to them driving the powder charge down the barrel and un-compacting it prior to properly igniting it. Frequently this is with loose fitting projectiles (power belts, minie balls, etc). In this case you may want to try lower power 'black powder' or substitute labeled primers. These other primers may stick in the nose; requiring a dry fire to remove. I wrote about that here for the Remington 700 in the badgers den. Never use low power/black powder/Triple Se7en primers with Black Horn 209!

As for best loads, that's a hard one: I wrote a lengthy article in the Badger's Den about it that you should read in regards to the Remington 700. It must be noted that the Ruger 77/50 is similar but the shorter barrel doesn't allow burning all the powder at higher loads.

Q: How easy is it to install the Badger Ridge 209 conversion? Can I do it myself?

A: We do not sell Do-It-Yourself (DIY) kits to convert the Ruger 77/50; its too complicated to Do-It-Yourself. So for the Ruger your only option is to send in your bolt, or purchase an already converted bolt from us.

For the Remington 700 ML/MLS rifles the conversion is a little less complicated. So we do sell the conversion kits for Remington 700 ML rifles. Though typically if you have to ask "Can I DIY," I think the answer is simply to have us do it, or take the rifle and the kit to a competent gunsmith. When clients get me on the phone and ask me this question I answer it with the following questions:

- Have you read our online Remington installation guide? Do you have the tools an skills it shows? Can you go to a hardware or tool store and buy them? Can you make a bolt tool, aka "Tool 002"? What do you think the tools and pieces you'll need will cost? Will you use them again? Is it just cheaper and easier to send your bolt to us for conversion?

- Do you have calipers and can you measure things to within a thousandth of an inch?

- Do you have files and can you file things skillfully to within a few thousandths of an inch?

- Do you have a vice with jaws that open to at-least 6 inches?

- Can you recognize, repair, or replace an unsafe component? What is the outcome if you fail to do so?

The most common thing I sell to people who do-it-themselves and mess it up, are new firing pins. They just seem to get it wrong when filing, and shaping the pin. Some don't really understand the math to calculate firing pin protrusion. In these cases, it's cheaper to pay me to do it than to purchase a new pin. Why not transfer the risk of messing up filing the pin to me?

No matter what you answer to those questions, or what rifle you have, I recommend that you choose Badger Ridge's install service: all you'll have to do is purchase the kit with installation, and mail your rifle's bolt to the address on your emailed receipt. We'll do the modification (we always replace the Remington's main spring with a new one) and send your modified bolt back with a new breech plug and vent liner (see the installation service page for the details).

When you have us do your conversion, once you get your bolt, you'll need to assemble the rifle per the owners manual and on the Remington you may need to tune the breech plug with a letter C bit to feed your choice of primers). Keep it Simple.

For the Remington 700 ML/MLS rifles the conversion is a little less complicated. So we do sell the conversion kits for Remington 700 ML rifles. Though typically if you have to ask "Can I DIY," I think the answer is simply to have us do it, or take the rifle and the kit to a competent gunsmith. When clients get me on the phone and ask me this question I answer it with the following questions:

- Have you read our online Remington installation guide? Do you have the tools an skills it shows? Can you go to a hardware or tool store and buy them? Can you make a bolt tool, aka "Tool 002"? What do you think the tools and pieces you'll need will cost? Will you use them again? Is it just cheaper and easier to send your bolt to us for conversion?

- Do you have calipers and can you measure things to within a thousandth of an inch?

- Do you have files and can you file things skillfully to within a few thousandths of an inch?

- Do you have a vice with jaws that open to at-least 6 inches?

- Can you recognize, repair, or replace an unsafe component? What is the outcome if you fail to do so?

The most common thing I sell to people who do-it-themselves and mess it up, are new firing pins. They just seem to get it wrong when filing, and shaping the pin. Some don't really understand the math to calculate firing pin protrusion. In these cases, it's cheaper to pay me to do it than to purchase a new pin. Why not transfer the risk of messing up filing the pin to me?

No matter what you answer to those questions, or what rifle you have, I recommend that you choose Badger Ridge's install service: all you'll have to do is purchase the kit with installation, and mail your rifle's bolt to the address on your emailed receipt. We'll do the modification (we always replace the Remington's main spring with a new one) and send your modified bolt back with a new breech plug and vent liner (see the installation service page for the details).

When you have us do your conversion, once you get your bolt, you'll need to assemble the rifle per the owners manual and on the Remington you may need to tune the breech plug with a letter C bit to feed your choice of primers). Keep it Simple.

Q: How long does it take for you to convert my bolt or build me a bolt?

A: This is a complicated matter to give a simple answer to. We always complete installations in the order the bolt's arrive. In the summer, when work is slow: Installation of a Remington 700 ML 209 kit is typically complete and in the mail two weeks after your bolt hits my hands. In the Fall when everyone wants their work done, and I also go hunting, this can grow to up to 4 weeks or more. Ruger 77/50 bolts, both those sent to me or ones I build from scratch, take a little longer: minimum 4 weeks turn around. Also (when we are able to make them) it will take a minimum of 2 weeks for me to build a Remington bolt from scratch. We don't 'stock' complete bolts; they are built as they are ordered. These times are from when a bolt arrives, until is is placed back in the mail.

That said, I don't like to sit on work. I get it done as soon as I can. Depends on my work load, and if I'm going hunting and other family constraints. But if you ask me for a time commitment, this is what you'll hear. There are more details in the Terms of Use page, that account for some holidays, vacations with the family, my own hunting habits, so actual turn around time may vary a little. If you contact us we'll give you the up-to-date current estimate.

That said, I don't like to sit on work. I get it done as soon as I can. Depends on my work load, and if I'm going hunting and other family constraints. But if you ask me for a time commitment, this is what you'll hear. There are more details in the Terms of Use page, that account for some holidays, vacations with the family, my own hunting habits, so actual turn around time may vary a little. If you contact us we'll give you the up-to-date current estimate.

Q: What size is the Letter C drill bit? What bit can I substitute for it? How do I tune a breech plug?

A: A letter C drill bit measures .242 inches. There is no substitute; using any other size bit to tune your breech plug to your primers will not be effective and will probably ruin your breech plug. We sell letter C bits individually and include them with our complete kit. Remember only the Remington breech plug -may- need to be tuned with a letter 'C' bit... (The Ruger is a crush seal, and doesn't need a C bit).

We have an entire section dedicated to Remington breech plug tuning... please check it out by clicking here.

We have an entire section dedicated to Remington breech plug tuning... please check it out by clicking here.

Q: What is a vent liner? Why and when do I need to change it? Why do you sell "Savage" vent liners for a Remington or Ruger rifle? How do I maintain and clean my Badger Ridge Hunter Breech plug with Lehigh Vent liner? Why do your vent liners look a little different from the one that came with my Savage 10ML-2?

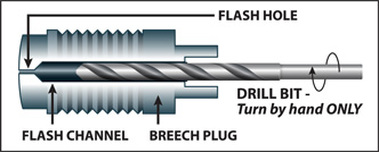

A: The Ruger 77/50's and Remington 700ML's original breech plug's design cause prolific blow back. The kit we sell does away with the OEM breech plug. Our's uses a breech plug with similar design to the Savage 10ML-II's breech plug. These types of breech plugs receive a 209 shot shell primer to seal in the end end that abuts the bolt, and have a sizable flash chamber that is threaded at the end that abuts the powder charge. This threaded end is constricted when the vent liner is screwed into it. Thus the vent liner's constriction or "flash hole" 'focuses' the primer's heat into a hotter flame front and into the powder charge. This produces hotter, more consistent ignition. The 209 primer seals the breech producing more consistent and slightly higher pressures. All these effects tend to increase shot to shot consistency (accuracy).

Generic Breech plug from Blackhorn209.com, note the plug depicted does not have a vent liner so once the flash hole opens the entire breech plug has to be replaced. The Badger Ridge Hunter plug uses a replaceable vent liner.

Generic Breech plug from Blackhorn209.com, note the plug depicted does not have a vent liner so once the flash hole opens the entire breech plug has to be replaced. The Badger Ridge Hunter plug uses a replaceable vent liner.

Mr. Ball's design that most of us know as the Savage 10ML-II essentially set the standard for the vent liner's form, but most agree Lehigh improved it. So the vent liners we sell are manufactured by the ruminants of Lehigh (Lehigh Defense was sold, so we no longer call these Lehigh Vent liners). Bottom line is that our vent liners are 17-4 stainless and are interchangeable with the Savage. So they are often just called "Savage type" vent liners.

The Badger Ridge 209 conversions come with one vent liner. As the the rifle is fired, primer residue will build up in the flash chamber of the breech plug and clog the vent liner's interior orifice. Maintenance and cleaning are required between range sessions. The breech plug's flash channel can be cleaned by a little light reaming with a drill bit just smaller than the hole (DON'T REMOVE METAL). Solvents will also help carry away any remaining residue.

Blackhorn209.com also has a good section concerning general 209 breech plug maintenance

The Badger Ridge 209 conversions come with one vent liner. As the the rifle is fired, primer residue will build up in the flash chamber of the breech plug and clog the vent liner's interior orifice. Maintenance and cleaning are required between range sessions. The breech plug's flash channel can be cleaned by a little light reaming with a drill bit just smaller than the hole (DON'T REMOVE METAL). Solvents will also help carry away any remaining residue.

Blackhorn209.com also has a good section concerning general 209 breech plug maintenance

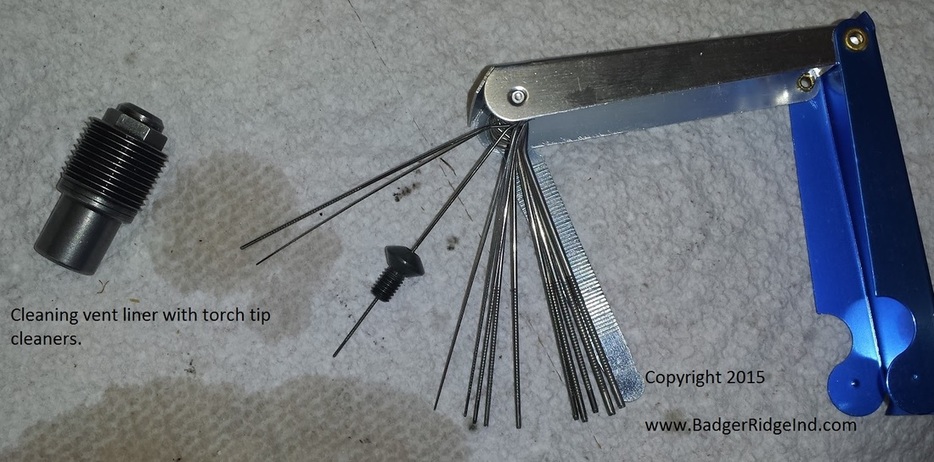

To clean the vent liner, we recommend buying torch tip cleaners from your local hardware store. In a pinch you may be able to get by with just a small paper clip etc. Once you locate the largest torch tip cleaner that can pass through, you can also measure its diameter and track the enlargement of the interior orifice (aka flash hole).

Each firing forces hot gases through the vent liner's constricting orifice and erodes it. Eventually the orifice enlarges too a point that pressure variations occur and accuracy suffers. Once a vent liner opens up too much, back pressure will become excessive and primer deformation will occur. See the pictures below for signs, but eventually the primer side wall will bulge excessively where not enclosed by the breech plug and/or split when the rifle is fired.

Each firing forces hot gases through the vent liner's constricting orifice and erodes it. Eventually the orifice enlarges too a point that pressure variations occur and accuracy suffers. Once a vent liner opens up too much, back pressure will become excessive and primer deformation will occur. See the pictures below for signs, but eventually the primer side wall will bulge excessively where not enclosed by the breech plug and/or split when the rifle is fired.

Torch tip cleaners are available at most hardware or welding supply stores. They are the best tool I know of for cleaning vent liners

Torch tip cleaners are available at most hardware or welding supply stores. They are the best tool I know of for cleaning vent liners

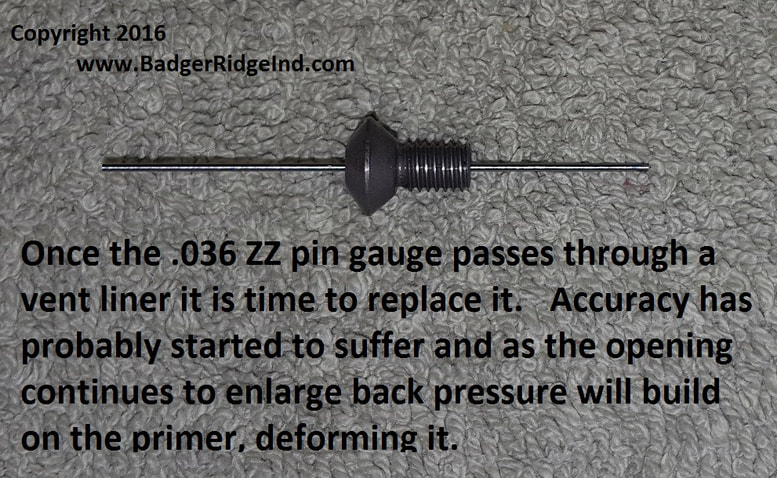

The exact number of firings one gets before the vent liner needs to be replaced depends on a lot of factors, such as powder charges, cooling times, primer types, maintenance performed etc. If you replace it when accuracy degrades, you won't have to deal with excessive pressures due the orifice being too large. The vent liner's orifice starts out at about .030 inch. Accuracy drops around .036. No one can tell you how many shots you'll get before your accuracy starts to degrade. But when it does; its probably time for a new vent liner.

That is why they thread into the end of the breech plug... They are relatively cheap and can be easily replaced. Most people find they can get somewhere around 50 to 100 shots or more out of a vent liner. But again, it depends on a lot of factors. Your mileage will vary. But don't worry; we sell replacement vent liners, and have the best price available!

That is why they thread into the end of the breech plug... They are relatively cheap and can be easily replaced. Most people find they can get somewhere around 50 to 100 shots or more out of a vent liner. But again, it depends on a lot of factors. Your mileage will vary. But don't worry; we sell replacement vent liners, and have the best price available!

Don't have the ability to measure your torch tip cleaners? Want to keep it simple and easy? You can also use .036 ZZ gauge pins to measure the orifice's diameter. Remember you want to replace the vent liner when it reaches .036. If you can't measure the diameter, replace it when accuracy drops. If you don't do it then, accuracy will continue to degrade and then you will begin to see unsafe pressures on your primers. Continuing shooting beyond .036 is not recommend. Unsafe pressures will develop.

Another way to handle the issue and not needing to measure anything: many hunters simply replace the vent liner at the beginning of the season before they check their zero. Then hunt through the season, shoot less than 50 shots, and replace it with a new vent liner a the start of the next season. Not necessarily the most frugal method, but it is safe and effective.

Note: the original all black Savage vent liners are slightly shorter than our vent-liners. If you don't clean the threads that the vent-liner screws into after removing one of the shorter vent liners, the new vent-liner may not fully seat. Some folks get confused and think our vent-liner isn't compatible: it is compatible, you just need to clean those threads! Try soaking in penetrating oil or ATF then either using a small wire brush or chasing the threads with a tap to get all the crud that impacted in the threads loose, then our vent liner should thread in and seat flush.

Another way to handle the issue and not needing to measure anything: many hunters simply replace the vent liner at the beginning of the season before they check their zero. Then hunt through the season, shoot less than 50 shots, and replace it with a new vent liner a the start of the next season. Not necessarily the most frugal method, but it is safe and effective.

Note: the original all black Savage vent liners are slightly shorter than our vent-liners. If you don't clean the threads that the vent-liner screws into after removing one of the shorter vent liners, the new vent-liner may not fully seat. Some folks get confused and think our vent-liner isn't compatible: it is compatible, you just need to clean those threads! Try soaking in penetrating oil or ATF then either using a small wire brush or chasing the threads with a tap to get all the crud that impacted in the threads loose, then our vent liner should thread in and seat flush.

Primers shot well beyond safe pressures.

Replace the vent liner! And or reduce powder charge to no more than 120 grains by volume!

Primers shot well beyond safe pressures.

Replace the vent liner! And or reduce powder charge to no more than 120 grains by volume!

Sure signs of unsafe pressure are:

-cratering around firing pin indentation on the primer

-flattening of the primer cup (loss of the round edge of the primer)

-warping, bulging, tears, etc in the side wall

-blow by getting past the primer that otherwise sealed fine (as the orifice erodes eventually the primer can't seal the pressure back and it bypasses an otherwise well sealed primer)

***Shooting without a vent liner installed is always a bad idea!!!***

-cratering around firing pin indentation on the primer

-flattening of the primer cup (loss of the round edge of the primer)

-warping, bulging, tears, etc in the side wall

-blow by getting past the primer that otherwise sealed fine (as the orifice erodes eventually the primer can't seal the pressure back and it bypasses an otherwise well sealed primer)

***Shooting without a vent liner installed is always a bad idea!!!***

This end receives the primer... Note its clean and free of primer residue

This end receives the primer... Note its clean and free of primer residue

I always recommend putting a little anti-seize on the vent-liner's and breech plug's threads after cleaning and before installation. But be sure to keep the interior of the vent-liner and breech plug clean and free of greases and oils to have consistent first shot ignition. I always take a look through the breech plug and make sure I can see a round spot of light through the vent-liner before I put it in my rifle and load. Also, some people discharge a primer through the breech plug before they load to be sure to clear it of any contaminates and ensure first shot performance.

This breech plug was fired multiple times with Blackhorn209 and left in a rifle for about 8 months before being removed. This is after it was scrubbed with steel wool.

This breech plug was fired multiple times with Blackhorn209 and left in a rifle for about 8 months before being removed. This is after it was scrubbed with steel wool.

Always clean your rifle soon after firing.

Never store your rifle with the breech plug in it.

Never store your rifle charged.

Even if its made out of 416 stainless IT CAN CORRODE

Q: Have you considered making a 209 muzzle loader conversion that can use a primed case instead of a 209 primer?

A: "Yes, but in the end it didn't make sense and did not make it off the drawing board."

Q: Then why does Remington use a '45ACP/30'06 like' primed case in it's new 700 Ultimate muzzle-loader?

A: "The 700 Ultimate is an entirely different rifle from the 700ML or the Ruger 77/50. The cases used by the Ultimate (similar to 30-06 cases with the shoulder cut off) have case head diameters that are too big for a proper breech plug in the 700ML or 77/50. Primer carrier ignition has been done in the customized 700ML's by using smaller cases like the 25ACP and 32ACP. A kit using this system would cost more to produce, and more complicated to stock/use. So what would anyone gain over what our current kit does with easily obtainable standard 209 primers? The only answer is that one who is set up to reload could save a small amount by using Magnum Rifle primers. Saving a little on primers with added kit cost, and complications like de-priming and re-priming hard to find cases isn't for everyone. So, it didn't make sense to produce a cartridge based primer carrier kit. A simple, solid, reliable, kit makes sense, so we are sticking with just the 209 kit we sell."

Q: What about 209 shaped primer holders that use magnum rifle primers (the holder is reusable)?

A: "Not worth it in our opinion for two basic reasons:

1: The primer carriers would require fitting to seal the breech properly, and add another level of complication. Folks who think this is an advatage believe that some how they are going to make some sort of savings (209's are typical more expensive than magnum rifle primers). Truthfully getting an actual savings of $ is not easily achieved for most of us. Remember, the savings is only achieved after many, many firings. To calculate how long it takes to just break even, the cost of the the 209 magnum primer adapter has to be added up from the --difference-- of price between magnum primers and 209's. I.e. if you spend $20 on a single primer adapter, you have to shoot enough that one primer adapter that the cost -difference- between the 209's and the magnum primers adds up to $20... that is a lot of shooting before you even come close to breaking even! And you are sacrificing simplicity to even try it!

2: The stainless steel we use in our kits is hardened and substantially harder than the metals used to make 209 primers. So all the deformation and wear is essentially limited to the primer.... which is discarded after firing. Using a magnum primer adapter changes that relationship. If it's made to last, it won't be made to be deformed & get a good seal, and may add wear to the conversion kit's components. The kit is the more expensive item! Why add wear and further risk it? That wear causes maintenance and replacement costs to go up in the long-run.

Thus: The use of standard 209 primers is effective and simple. Primer carriers (that's what a vari-flame or magnum rifle primer to 209 adapter is) are just an unnecessary, less effective, complicated expense, that is actually more expensive when considered properly.

1: The primer carriers would require fitting to seal the breech properly, and add another level of complication. Folks who think this is an advatage believe that some how they are going to make some sort of savings (209's are typical more expensive than magnum rifle primers). Truthfully getting an actual savings of $ is not easily achieved for most of us. Remember, the savings is only achieved after many, many firings. To calculate how long it takes to just break even, the cost of the the 209 magnum primer adapter has to be added up from the --difference-- of price between magnum primers and 209's. I.e. if you spend $20 on a single primer adapter, you have to shoot enough that one primer adapter that the cost -difference- between the 209's and the magnum primers adds up to $20... that is a lot of shooting before you even come close to breaking even! And you are sacrificing simplicity to even try it!

2: The stainless steel we use in our kits is hardened and substantially harder than the metals used to make 209 primers. So all the deformation and wear is essentially limited to the primer.... which is discarded after firing. Using a magnum primer adapter changes that relationship. If it's made to last, it won't be made to be deformed & get a good seal, and may add wear to the conversion kit's components. The kit is the more expensive item! Why add wear and further risk it? That wear causes maintenance and replacement costs to go up in the long-run.

Thus: The use of standard 209 primers is effective and simple. Primer carriers (that's what a vari-flame or magnum rifle primer to 209 adapter is) are just an unnecessary, less effective, complicated expense, that is actually more expensive when considered properly.

We decided our 209 sealed breech system comes out ahead, and dropped development of a cartridge case based primer carrier system, and urge you to stay away from magnum rifle primer to 209 adapters. Why fix something that isn't broken?

Check out the YouTube video above of our system in action. We think you will agree.

Check out the YouTube video above of our system in action. We think you will agree.

Copyright 2016-21 Badger Ridge LLC