|

We've been selling and installing our great 209 conversions for years now. And I've noticed my questions and sales following trends influenced by the various hunting seasons and their associated rules. This time of year many folks are getting ready for Colorado's muzzle loader season, typically focusing on harvesting an elk. So annually, I edit and re-post this one. The commentary here was also added the to the FAQ (Frequently Asked Questions). The FAQ entry: Q: I hunt in Colorado, sabots are not allowed for hunting during muzzle loader season. I want to use your awesome 209 conversion, but you say you recommend sabots with jacketed handgun bullets. What are my options? A: Short answer is our kit will work great with any projectile. I've found Pyrodex, Triple Se7en, and black powder work best with non sabot projectiles. So I suggest that you use our kit and any muzzle loader safe powder (besides BlackHorn209) for your Colorado hunts with Colorado legal projectiles. Long answer: I realize not all 50 state have the same rules. And some state’s rules are just plain silly. I wrote a blog post about that. The main thing to remember here: the powder you chose must be compatible with the projectiles you use. Our kit will seal the breech, which keeps the crud out of the bolt and action no matter what muzzle loader safe propellant you chose. Our kit is compatible with all muzzle loader safe propellants: pellets, loose powder, etc. Also using 209’s will give you more ignition heat and thus more reliable ignition over caps. And seeing our system keeps the crud sealed into the breech plug, the 209 is ignited reliably too. But the powder and projectile choice is up to the shooter. Read the manuals/instructions and follow them when developing loads. Blackhorn209 powder is different from Pyrodex & Triple7even: To be reliable BlackHorn209 needs to be fully sealed; i.e. sealed at the breech (which our kit does), and sealed at the projectile. Minnie balls, minet, power belts, B.O.R. Lock MZ and other easy loading projectiles that are legal for Colorado muzzle loading, don’t usually seal until the powder combusts and forces them into the grooves. This deformation sealing the bore after combustion is called obturation. The problem is BlackHorn209 doesn’t burn well until it’s sealed and can build pressure. So it’s likely to have bloopers, miss fires, and hang fires with obturating projectiles. Sabots seal well to start, thus if you are using BlackHorn209, it’s recommended to use sabots. Though the new Hornady Bore Driver bullets are reported to seal well and work with BlackHorn209, I haven't tried them myself. Never use smokeless powder in your Remington/Ruger! It says it right on the barrel! Because Colorado doesn’t allow sabots during the muzzle loader seasons I would stay away from Blackhorn209. (or with a lot of trial, I may try the Hornady Bore Drivers) Otherwise, If I was hunting in Colorado, I’d use our kit, choose a heavy projectile (250gr or more) that seals on ignition: Hornady BoreDriver, Thor, minie ball, lead conical, etc. But without a lot of testing, I wouldn’t use BlackHorn209; I’d try Triple7even, or Pyrodex. Although they are not as easy to clean, and will foul the barrel, they are very easy to ignite even when not sealed, and will obturate the projectile. Black powder will work just fine with these sorts of projectiles too. I do have a few clients that report success with Blackhorn209 and magnum primers (CCI 209M or Federal 209A) using Hornady FPB’s or its aformentioned replacement Bore Driver... and also with Thor bullets. I also had one that said tthe Thors worked well at the range, but didn’t fire when he had a nice bull in his sights. He said it was extremely chilly that morning, his rifle was cold soaked, and the Blackhorn209 wouldn’t go bang. He was very frustrated. I suspect it was because the projectile shrunk with the cold, and the copper jacket wasn't quite as malleable. Also cold powder is just a bit harder to get burning, and thus that setup was unable to obturate the looser projectile and keep the BlackHorn209 burning. Thus without a lot of testing (like putting a loaded rifle in a freezer, pulling it out and shooting the combo... repeatedly). I would stick with Pyrodex or TripleSeven for Colorado muzzle loader hunting: they will go bang with an obturating bore riding projectile when you need it, even when it is very cold. Just about everywhere else, I recommend sabots because they have been accurate, easy to load, and jacketed hand gun bullets have always been very effective for me. Whatever powder you chose, the velocities your muzzle loader will produce are essentially the same that good jacketed hand gun bullets are designed for. They tend to kill quickly and bring home game. Sabots are allowed in most states, so that's what I usually recommend. Long-term: If I voted in Colorado, I’d pressure my legislature to change the muzzle loader rules. Removing the most effective projectiles (jacketed hand gun bullets are great in muzzle loaders), and the most modern muzzle loading propellant (Black Horn 209) from use is bad for the game receiving the projectile. I believe the no sabots rule promotes wounded/lost animals.

0 Comments

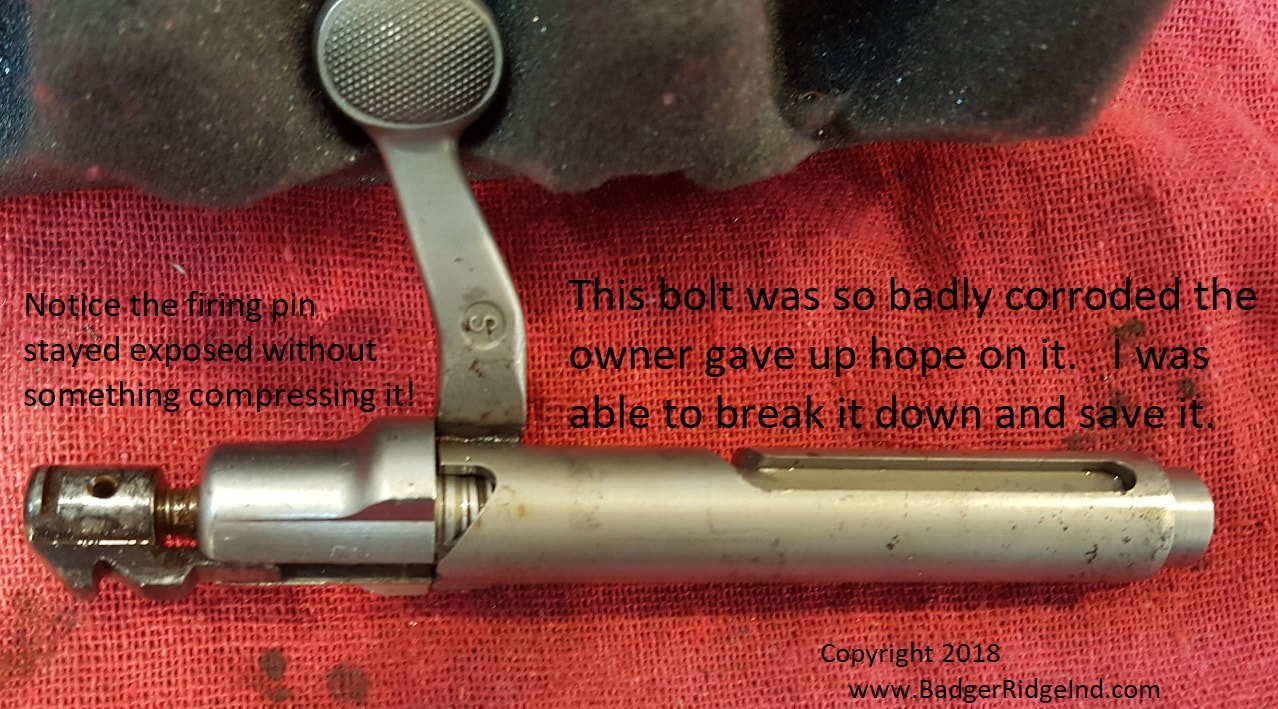

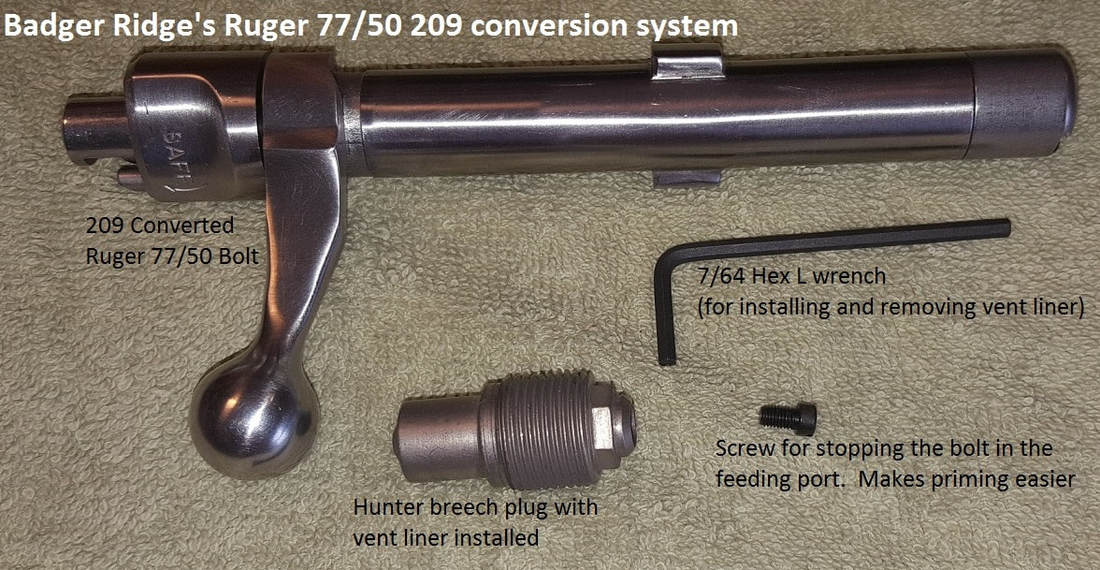

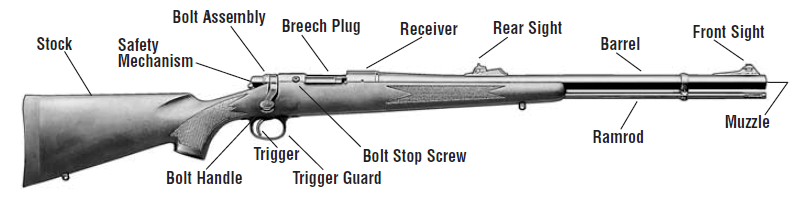

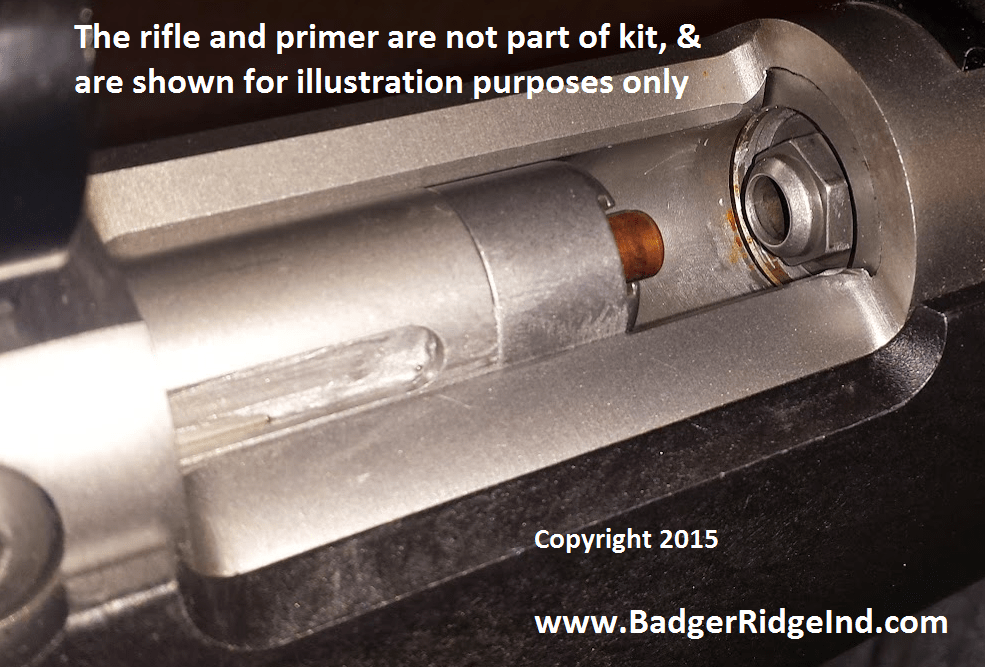

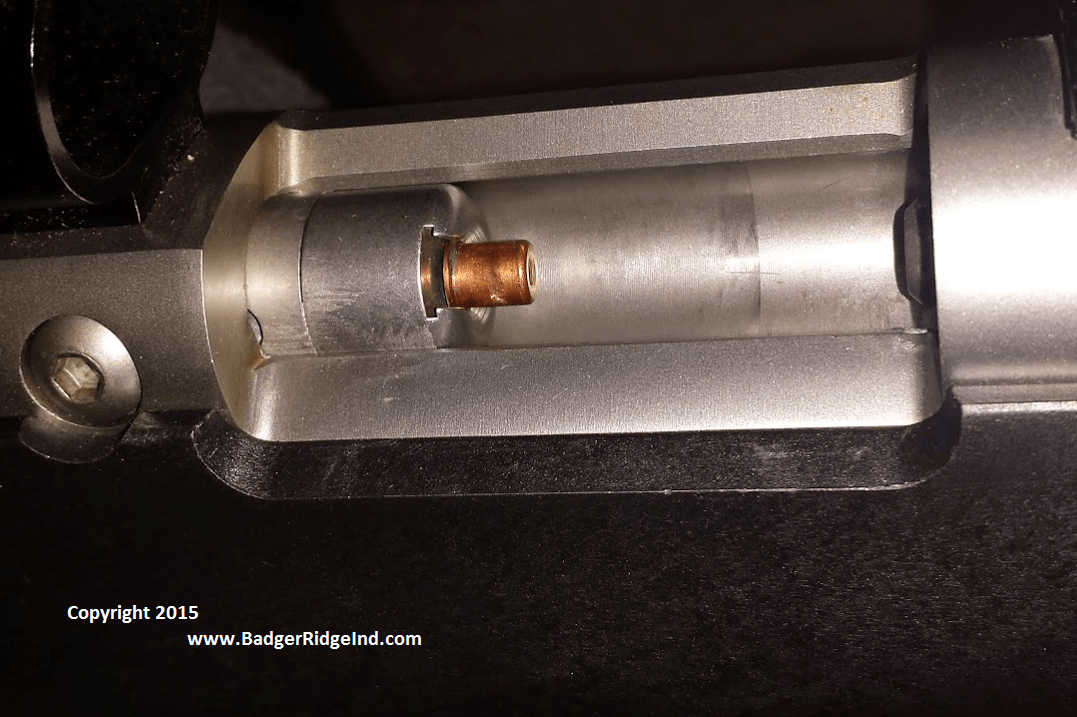

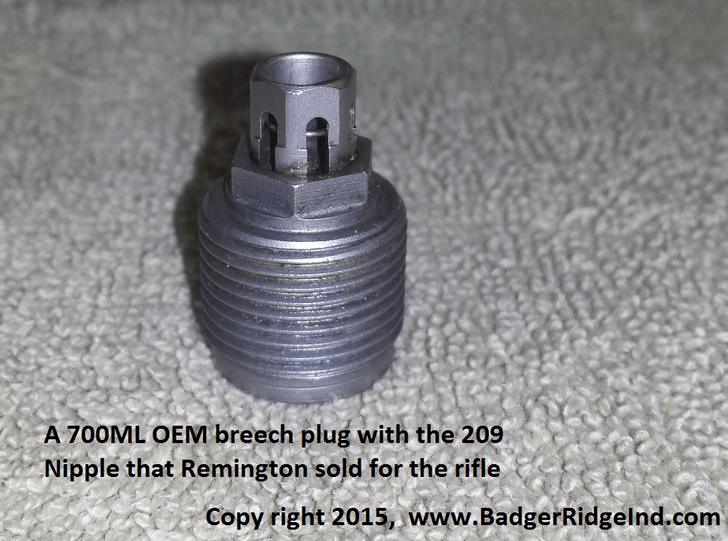

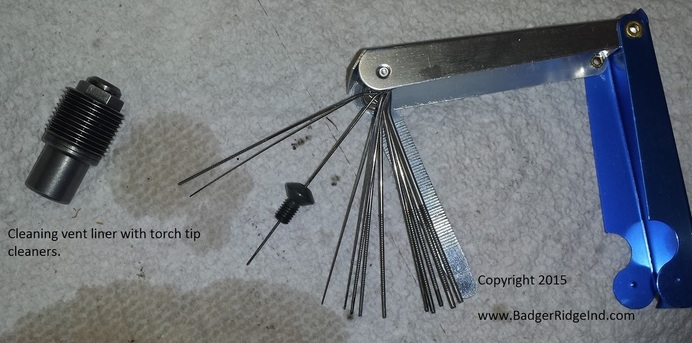

I'm consistently getting asked the same question: Q: "What primer should I use with your Remington 700 ML 209 conversion kit? I usually give the same answer: A: "I'm my Remington's I use the old copper colored standard CCI 209 primers. The new CCI's you can buy now are silver and have slightly different dimension. The old copper colored ones have never given me any trouble, but I don't have enough experience to recommend the new ones (they are probably fine, I just don't have much experience with them). If I didn't have the old copper colored ones, I'd probably start with a standard Federal, their 209A, or the Remington STS 209's. I'd stay away from Winchester. The Winchesters burn hot and ignite BH209 fine, but they tend to balloon and stick in the nose, so I avoid them. If all you have is Winchester, you may have to dryfire on the spent primer to remove it when it sticks." "In my Ruger 77/50 I use whatever crushes without having to use shims. Just a simpler solution." Then the next question either goes: Q: "But the Blackhorn 209 site recommends, CCI magnum 209 primers?" A: "That is true, however I've had the magnums stick in the bolt nose at lower powder charges and require a dry fire to remove, so I personally stay away from them. If you don't mind dry firing in-order to get the spent primer out of the nose, or you work up to higher charges, you can use them (or any other 209 primer). I've personally had great accuracy and performance with the standard old copper colored CCI and Blackhorn 209 so that is what i use. Federals and Remington STS primers work good too. With our Remington kit, you can really use whatever primer you tune your breech plug to. For the Ruger you can use what gives you a proper crush seal." Or the next question is: Q: "I'm using Pyrodex/TripleSeven/Black powder, I've heard full power primers are too powerful, and will drive the powder down the bore, un-compacting it, and gives inconsistent performance, and poor ignition." A: "That can happen. I believe its most probable with loose fitting projectiles (like minie balls, power belts, Bore locks etc). I stuck with tight fitting Sabots and standard CCI's and was OK back when I shot TripleSeven. Feel free to follow proper load development practices and experiment with other 209 primers. I myself have always been pleased with standard CCI's." "If standard 209's are not giving you the accuracy you want (with black powder substitutes other than Blackhorn209) you may want to try the low power "black powder" only primers. I'd try the ones with the same name as the powder you are using. However, understand, that they may stick in the bolt nose and require a dry firing to remove. ie Winchester 777 primers." If sealed breech and 209 primers are legal for hunting in your state (only Idaho and Oregon restrict sealed breeches and 209's), I suggest you give our kit with Blackhorn 209 a try (and only with regular full power shot shell primers). Blackhorn 209 has given me better performance in every way imaginable. But remember Blackhorn 209 will not work with the low powered "black powder" primers; they don't have enough heat to consistently and fully ignite Blackhorn 209. Check out the video below for real world examples of our Remington 209 kit using old copper standard CCI's functioning just fine with BlackHorn 209 In the video below I shoot a rifle I just converted to sealed breach 209 primers. I used Blackhorn 209 and CCI magnums at 80 grains by volume (a minimum charge), and I got a few sticking primers that required a dry-fire to remove.  Welcome to the website with the only conversion kit you'll ever want on your Remington 700 ML or Ruger 77/50. I've been writing and updating this blog for years. If an internet search brought you here, you will find what you are looking for by reading through these articles or finding the topic you are interested in along the right hand side. The Remington 700 ML and Ruger 77/50 are our specialty. They both came from the factory with the same fatal flaw: blow-back coursing backwards through the bolt from each firing. The Remington and Canadian 209 mods didn't improve this. If anything they only made blow-back worse. If not quickly and properly cleaned after firing the bolt will corrode and freeze up. Our kits correct this fatal flaw by sealing up the breech. But not everyone has our kit yet, and seeing these rifles are all 10 to 20 years old, it's all to common for some one to have shot and then put it away without a proper cleaning. Be thankful if the bolt was at least removed! Getting a frozen bolt out of a rifle is a nightmare! I was contacted by a Remington 700 owner who admitted he shot his rifle a few years ago, removed the bolt but never cleaned. He had soaked the bolt in penetrating oil for a couple of days, but he couldn't get it to budge. I recommended he buy our 209 conversion with installation, send me the bolt, and if it wasn't too much additional work I wouldn't bother him. He was on a tight budget and couldn't afford our 209 conversion. So, I told him to purchase our legacy mainspring replacement service and ship me the bolt. We'd go up from there as my time and replacement parts required. We have new bolt bodies, mainsprings, and more! Once I got the bolt in my hands, it looked like any other Remington 700 bolt with the Canadian 209 mod, but indeed I couldn't compress the mainspring nor get it to move when I put it in a rifle. I proceeded to soak it a couple of days in penetrating oil as well. After the penetrating oil bath it still wouldn't budge, so I put it in the jig I made for these bolts and pushed on the firing pin with my 12 ton press. That worked! The firing pin finally gave way and "protested" a little as it protruded. From there I had to cut the firing pin off at point where it threads into the cocking piece. I removed the remnant threaded end from the cocking piece. Then I reversed the bolt in the jig and pressed out the pin from the back: Because it was corroded through in multiple places: most of the mainspring came out (in 3 pieces) with the firing pin, but not all of it. The bolt plug wouldn't unscrew, even after I cleaned it up. I realized the back end of the mainspring had fused itself to the bolt plug, so back into penetrating oil for another night. The next day I managed to get the bolt plug to break free of the body. Removed the mainspring that had fused itself to it, and cleaned up all the pitting. After a lot of cleaning, scrubbing, and gingerly re-freshening of threads: the cocking piece, bolt body, and bolt plug ended up being serviceable. As I had to sacrifice the original firing pin to get it apart, I pulled an old used Canadian firing pin out of my junk bin. All I needed was a new mainspring to put it all back together. The client made my additional trouble 'right' with a few more dollars and it all went back in the mail. While the customer is always right, and he is very happy... I have to admit it didn't sit right with me to do so much work just to leave the bolt with a leaky setup that will likely fail even if properly cared for... and if neglected it will totally lock up again. I really felt this rifle needed our sealed breech 209 conversion. But the customer is always right. Hope this has helped you. If we can help you in anyway (perhaps with a Ruger 77/50 or Remington 700 ML) please use the Contact page to reach out. We usually reply within 24 hrs. Be sure to mention what type of muzzle loader you have!  Badger Ridge's Remington 700 ML 209 Conversion kit Badger Ridge's Remington 700 ML 209 Conversion kit From what I've been able to gather there is a good bit of variation on how people learn about our awesome 209 conversion. While we have a lot of repeat customers, and folks learning about us through word of mouth, most arrive here after an internet search. Frequently newcomers are having problems with their rifle and looking for replacement parts or guidance on how to troubleshoot their woes. If you are tired of blow-back (aka blow-by), blowing up 209 primers, priming/de-priming tools, having misfires, hang-fires, bloopers, or trouble setting off Blackhorn209: Our kit is the fix, but it's not a $20 solution.  Our "drive train" fix in action Our "drive train" fix in action I understand the desire to find a $20 fix, but for the 700 ML/MLS, especially with the many years they all have on them now, there isn't a $20 fix. A lot of folks who end up here realize quickly that our kit is the right solution, but for others they are stuck on the $20 fix. A good analogy is if this were cars... sometimes it feels like some folks are skeptical I am ethical when I tell them an entire drive train overhaul is required; they are looking for wheel weights to stop a wheel vibration. The truth is: the reason it's throwing wheel weights is that it has a bad drive train! We can fix it, and you'll love your rifle afterward. Trust me; take the time to understand the problem isn't the wheel weights! You get what you pay for!There are so many little flaws in the original system: blowback getting into the bolt, shooter's eyes, and burning the scope are chief among them. Then they get amplified with age, corrosion, use, and abuse; as soon as one is fixed another will creep up. Then the rifle doesn't go bang when desired. So it doesn't make sense to spend a dime to keep the original system running. The only exception is when someone hunts out west where some hunts prohibit 209 primers or sealing of the breech. But even for those folks we offer entire 209 converted sealed breech bolts and breech plugs so they can switch to sealed breech on hunts where it's legal, and keep their original system for hunts that it is not. One rifle can meet both requirements with a bolt and breech plug swap. But therein lies the rub... a small minority -have to- keep the original system running for those special hunts. So for those select few I'll share how I'd try to keep the original system functioning (though my goal is to get those non 209, non sealed breech states to come to their senses and convert every Remington 700 ML to our sealed breech system). What I would do if forced to keep the original system running:My goal here is to help you understand where the original goes wrong, and unless you hunt out west this should also show you why you need to dump the original and use our 209 conversion. But here we go: - If legal I'd use 209's; if the rules prohibit 209's then i would use musket caps. I'd dump any #11 percussion cap system. 209's and musket caps are hotter and more reliable than #11's. The nipple can be removed from the breech plug with wrenches. One must be careful not to damage any threads. New breech plugs are available if the nipple won't come out. I'd put a small dab of anti-seize (or choke tube lube) on the threads of the new nipple so I could replace it later when it mushrooms. And it will mushroom. - Unless someone has owned the rifle since it was new, they don't know what sort of swapping and fiddling has been done to it. Not all strikers are equivalent, nor do they all work with the same primers/caps and nipples. Remington had two different firing pins for the rifle. Their first version only did percussion caps, then they released the 3 way system where one pin could discharge all three (209's, #11's, & Musket Caps). Plus the Canadian mod is out there as well, but it only does 209's.  Leaky Canadian 209 nipple Leaky Canadian 209 nipple I've seen rifles with the original flat firing pins installed with 209 nipples. The folks who had this set up contacted me complaining that the rifle wouldn't fire! Of course it won't fire with the wrong firing pin! Remember, the Remington 3 way ignition system had a raised central area for discharging the 209's, and also worked with both types of caps. But it needs to be coupled with the proper Remington style 209 holder. The Canadian won't work unless its coupled with it's unique primer holder. Whatever leaky original system used, it'll need priming de-priming tools as well. Who wants to try and find all that for a reload in the field? The original system is known for blowing up primers and needing special picks and tools to prime and de-prime the rifle. - I'd completely disassemble and clean the bolt and firing pin assembly. That means tearing the assembly totally down, scrub and clean all fouling and corrosion from every nook and cranny, and replace the mainspring. Our installation tutorial will prove useful here. If that is too much for you to do, I can replace the mainspring on your bolt for you. - I always ensure the rifle is unloaded and empty, and in a safe area I shoot some caps/209's to ensure the rifle will set them off. Remember even caps/primers will shoot things out the barrel with enough energy to hurt, maim, or blind. So if you decide to to this, ensure the rifle is unloaded per the procedures in the manual, keep the rifle pointed in a safe direction, and at a proper back stop. -Crud and misshaped nipples prevent caps/primers from properly seating. Then when the striker hits them instead of detonating, it pushes them forward towards a proper seat. Then once seated, a subsequent strike can set it off. Sometimes the nipples/primer holders get so mashed there is no saving them. I'd clean out any crud, and correct misshaped nipples (I'd say its usually best just to replace with a new nipple). - If the first strike doesn't set off the cap/209, I'd try a second, third, fourth, or fifth before trying another cap/primer. If a subsequent strike on the same cap detonates it, I'd suspect a misshapen nipple/primer holder. If none of them set it off, it could be the nipple or it could be the bolt/mainspring (but with a good tear down, correction to any corrosion, goo, fouling, proper lubrication and new mainspring, I'd suspect the problem lies in the the nipple). The repeated strikes the nipple receives eventually mushroom and mis-shape it. Even the 209 holders/nipples suffer this fate. Though the Canadian system will probably outlast the Remington vented 209 primer holder. But that is just degrees of bad... I wrote about how bad the Canadian conversion was in one of my first posts to this blog. - Each time the original system is fired, blow-back pulses the mainspring back and away from the nipple. At higher loads it can even drive back the firing pin into your thumb if you were to place it near the tang! (It hurts... trust me) These cycles and extreme compression coupled with the heat and corrosion then deteriorate mainspring life. Blow back coats the firing pin assembly in a corrosive sticky mess. I would tear down and clean after each time the rifle is shot, and I'd do a complete tear down and get everything out of every nook and cranny after each season. Blow back will find its way into the inner recesses of the bolt plug and cocking piece... trust me on this. I've torn hundreds of 700 ML bolts down. I'd replace the mainspring on the original system every few years. Again, I can do that for you if you like. Why our system is betterSo with the variations of the original system a shooter will have all those issues to deal with and think through. Once they fix one, soon another will creep up and cause issues. Those are a lot of inherent pit falls. All the while dealing with the blow back shooting into the bolt, a shooter's face, and all over the scope. Seems much smarter to me to rid oneself of that entire mess, use our sealed breech 209 system, and not be forced to strip a bolt down every time you shoot. Why don’t we sell any replacement parts for the original system nor the Canadian? I don't like to sell things I don't believe in nor use my self. Though the main spring is the same and we will replace it for you regardless of what system you use. I don’t want to be on the hook to keep something running that is flawed at its core, so I don't sell or support it beyond changing mainsprings. But I'll gladly replace the old leaky system with our sealed breech 209 system for you. Any state forcing folks to use that sort of system is beyond logic to me. Our 209 system seals the blow back in, which vastly reduces bolt strip downs and cleaning. With our system one only needs fingers to prime/de-prime, and the only parts that wear are the 209 primer (which is discarded after every use), the vent liner which is cheap and easy to replace (and the rifle will still go bang when its time to replace it), and arguably eventually someone will have to replace the mainspring. Mainsprings always have a finite life. It is true on any center-fire rifle; springs will eventually wear out. However the mainspring lasts much longer in our conversion because it is spared all the extra cycles, heat, and corrosive blow-back of the original. Also even if someone was to fail to seal the blow back in with our system (i.e. it seeped around a primer somehow), the bolt nose and the 209 primer itself essentially block any blow back from making it inside the bolt. With our system a shooter only has to tear the bolt down and clean it as often as they would a center fire rifle... which is not that often, perhaps as often as replacement of the main spring is required on a center-fire 700. You don’t have to take my word for it, you can read our customer feedback section and see for yourself in the video below. With our Remington 700 ML 209 conversion kit, we get very few complaints or requests for assistance compaired to the number of kits sold and installed. The few instances usually are tied to not fully comprehending the kit's components and how to maintain them. Of these, most center around the Badger Ridge Hunter 209 Breech plug. There is a good section in our FAQ on the breech plug and how to maintain it. The other complaints center around not understanding the subtle differences when using Blackhorn209. TROUBLE SHOOTING AND COMMON MISTAKESYou must read and understand the Remington 700ML owners manual prior to using our conversion kit. Using our 209 conversion replaces the breech plug; so you have to apply what the Remington 700ML Owner's Manual says about nipples, flash holes, and caps to flash channels, vent liners, and 209 primers. Failure to Fire, Misfires, Hang-Fires, Bloopers, etc: Typically these sorts of malfunctions are caused by one or a combination of: -1. Using blackpowder primers with Blackhorn209 -2. Obstructions or contaminants in the flash chamber (improper maintenance) -3. Failure to seal and compact the charge when using Blackhorn 209. -4. Not replacing the mainspring during conversion/poorly installed conversion, improper firing pin protrusion, using oils/grease that gel when cold, etc. First and foremost: The mainspring should be replaced during conversion. The original configuration subjected the mainspring to lots of corrosive blow-back, heat, and extra cycles. All quickly reduce its effectiveness. If not replaced, light and inconsistent primer strikes are probable. Also if the firing pin protrusion was not set properly, or there is a bur, rust, or crud causing the firing pin to hang up, failures to fire are probable. We always replace the mainspring as part of our installation service. If you did it yourself and are having trouble with detonating the primer: Take the rifle to a competent gunsmith to remedy these or any other unsafe or abnormal condition. Use only standard shotshell, full powered 209 primers with Blackhorn209. I recommend and use standard CCI’s!!! Remedies for obstructions or contaminants in the flash chamber/improper maintenance: -- Clean the flash channel of the breech plug with a 7/32 drill bit (only use your fingers and light pressure... do not remove metal!!!) Use standard bore cleaning solvents to dissolve any remaining contaminates and remove. Clean the flash channel of the vent liner with torch tip cleaners. Break cleaner works well to remove oils and greases and any remnants. Remove any lubricants, greases, or oils in the flash channel prior to loading. -- Keep anti-seize only on the threads of the breech plug and vent liner; anti-seize or any other lubricant will reduce primer heat and cause ignition problems when in the flash chamber, or face of the breech plug. -- Swab out any excess oil left in the barrel with a dry patch before loading In cold climates avoid greases and oils that gel or congeal when cold -- We use and recommend only dry PTFE lubes on the firing pin assembly If you are using full powered primers and doing the above maintenance and still having issues only when using Blackhorn209 (typically diagnosed by successfully and repeatedly igniting a load of other easier to ignite black powder substitute), the cause is most likely a poor seal on the primer or projectile. Poor primer seal can also be diagnosed by having soot or blow back on the sides of the 209 primers; only the primer’s face should have soot on it: -- Seal Primer: full power 209 shot shell primer swaged and sealed properly into the breech plug; one should feel some resistance when closing the bolt with a primer in the nose. This is because the primer is being swaged into and sealing the breech plug. Failure for the primer to seal is commonly caused by over or excessive breech plug tuning, or poor primer fit. Correct by changing to a larger size brand of primers (some European manufactured tend to be bigger), or purchase a new breech plug & do not over tune. -- Change projectile: Powerbelts, Bore Locks, Minet, Lubed conicals, Minnie-balls, Hornady FPB etc do not fully seal (aka obturate) until the powder charge expands and presses them into the rifling grooves. Use snug fitting sabots with properly sized bullets with Blackhorn209. -- Change powder: Black Powder and its other substitutes will combust easily and work OK when not completely sealed, but Blackhorn209 needs a good seal for proper ignition. Changing powders when one has a a poor seal is circumventing the problem rather than fixing it. So in summary: 1> You need to make sure your 209 conversion kit is properly installed 2> You still have to clean the crud out of the flash channel like you would any muzzleloader, it just requires a few different tools. In many ways it is easier than taking care of a side lock. Dry PTFE lubes work great on the firing pin and action at all temperatures (hot and cold). 3> When you change to Blackhorn209 those weak 209 black powder primers aren't going to do it. 4> And the old school, easy load, seals with combustion, projectiles don't work well with Blackhorn209 neither. Keep it simple: Use our kit with modern sabots and properly sized bullets, standard 209 primers that swage and seal, and you'll nearly certainly be malfunction and blow back free. |

Welcome to the Badger's Den!

|

|

|

Written by:Tom, purveyor of fine products. |

Archives

March 2024

August 2023

June 2023

March 2022

December 2021

September 2021

February 2021

January 2021

September 2020

April 2020

January 2020

October 2019

September 2019

May 2019

January 2019

November 2018

July 2018

May 2018

April 2018

February 2018

January 2018

November 2017

October 2017

August 2017

July 2017

April 2017

February 2017

January 2017

November 2016

October 2016

September 2016

August 2016

July 2016

June 2016

May 2016

December 2015

November 2015

October 2015

September 2015

August 2015

May 2015

April 2015

Categories

All

AR Stuff

Blackhorn 209

Customer Feedback

Hunting Gear & Accessories

Maintenance

Organization

Remington 700 ML/MLS

Ruger 77/50

Savage Muzzleloader

Troubleshooting

RSS Feed

RSS Feed