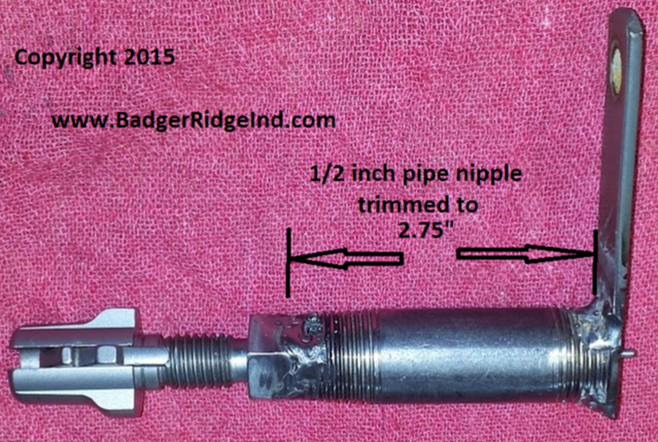

You know you have a great product (like our sealed breech 209 conversions) when so many of your customers take the time to write such detailed, complete, messages. Below is what Al R from Indiana had to say about our Remington 700 ML 209 conversion that he installed himself. For purchasing information click here, or on the pictures of the kit. If you don't want to read his insightful feedback, feel free to click the topics along the right side to find what you want concerning our Ruger and Remington 209 conversions (or click any of these blue links). Good morning, Yesterday I converted the bolt on our family-owned Remington 700ML. My son, Matt, (who is much more computer savvy than I am) ordered it about 7 or 10 days ago. For the sake of you knowing how much mechanical background this (very satisfied) customer has, in 1966 I was an apprentice tool-and-die guy. Within a year or so in the apprentice program I changed career course and enrolled in engineering school, which has paid the bills for the last 50 years, until my retirement. Over the years I accumulated a small hobby garage machine shop (drill press, vertical mill, engine lathe, shaper, welders, etc.). I consider myself an upper-echelon, non-professional, hobbyist. With those credentials, I hereby give a grade of “A” to Badger Ridge for your VERY complete instructions (both electronic and hard copy) and the materials kit for making a Remington 700ML 209 Bolt Conversion. Certainly the key to doing the conversion yourself is “Tool 002”. I’ve attached a photo of my rendition of “Tool 002” that didn’t require welding. (It was only 10°F here yesterday in central Indiana, and I didn’t want to have the shop doors open to do the welding). The B/M for my “Tool 002” is: (1) short piece of angle or barstock (2) #10 ViseGrip pliers (2) ½-13 nuts (while square is best, heavy hex would be ok, and standard nuts would work) (1) ½-13 hex head cap screw, drilled to accept firing pin The other suggestion I have is to recommend that when tapping the cross pin (out and in) the instructions need to prescribe support, or it will bounce, (and eventually bend), I suppose. I used a machinist V-block, but anything could be shimmed up and made to work. As to tuning the breech plug, Fiocchi 209 primers will not fit in my rifle without tuning. I can’t wait to get the scope mounted and some Blackhorn powder and take the gun to the range, once it warms up. On a larger picture, projects like 209 Conversions make America stronger, as DIY people who do these types of projects are problem solvers that extends way beyond a single 209 Bolt Conversion. I’m a strong believer in “Made in America”. I’m glad to see that you’re doing your part. Best wishes to Badger Ridge for 2018, and keep up the good work!! Sincerely, Al Al, Thanks for the kind words, encouragement, and insight on an easy way to improvise a firing pin tool. As for the cross pin removal: I like to use the pipe nipple with the welded nut bolt tool on 700ML's... it holds it all very well, and holds best when clamped in my vice. Makes tapping the pin out a breeze. With this tool I've had little trouble removing all but the most stubborn cross pins. If the pin doesn't want to budge, usually trying from the other side is all it takes. However for the really stuck ones, I do place the cocking piece on the anvil of my vice, or in a V block and use hard strikes to remove the pin. When putting it all back together, using the roll pin we include with the kit (and de-burring the pin with a little light filing) usually requires little undue force. I tend to use the tool I welded up quick (two nuts welded to small angle... similar to the one you shared) when I work on un-threaded cocking piece firing pins that have to have solid dowel pins... and with solid dowl pins, I pre drill 3/32, then disassemble & chase each hole individually with a #41 drill bit. This way the solid dowel pin floats into place (so there is little friction on the pin requiring hard strikes).

As for primer recommendations: Yes, Fiocchi and other European 209 primers are typically fatter than US primers. (I used recommend standard CCI but now that CCI changed their dimensions and color [now they are silver] I cannot recommend them, and instead suggest Federal or Remington primers). With most of these you will probably have to tune. Remember if a primer sticks in the nose, a dry fire usually will loosen it. Thanks again for writing in and allowing me to share your message with everyone, Tom

1 Comment

mark luchka

1/20/2021 12:38:00

installed a remington

Reply

Leave a Reply. |

Welcome to the Badger's Den!

|

|

|

Written by:Tom, purveyor of fine products. |

Archives

March 2024

August 2023

June 2023

March 2022

December 2021

September 2021

February 2021

January 2021

September 2020

April 2020

January 2020

October 2019

September 2019

May 2019

January 2019

November 2018

July 2018

May 2018

April 2018

February 2018

January 2018

November 2017

October 2017

August 2017

July 2017

April 2017

February 2017

January 2017

November 2016

October 2016

September 2016

August 2016

July 2016

June 2016

May 2016

December 2015

November 2015

October 2015

September 2015

August 2015

May 2015

April 2015

Categories

All

AR Stuff

Blackhorn 209

Customer Feedback

Hunting Gear & Accessories

Maintenance

Organization

Remington 700 ML/MLS

Ruger 77/50

Savage Muzzleloader

Troubleshooting

RSS Feed

RSS Feed