|

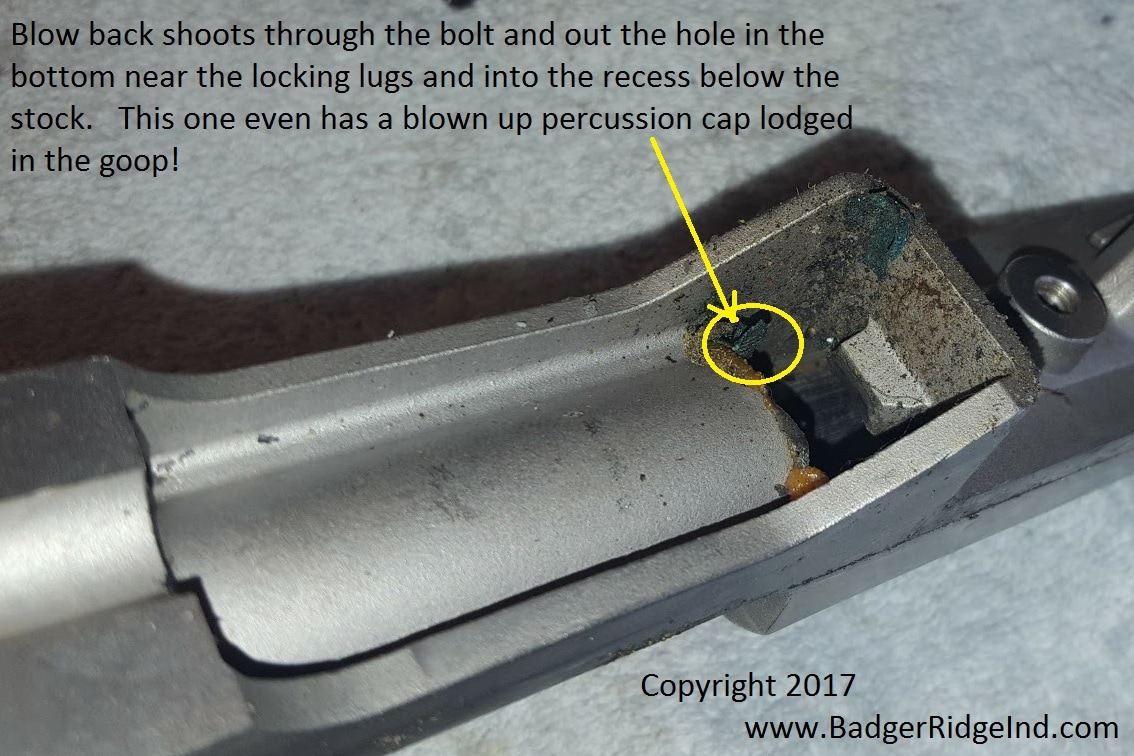

Before we only offered a 209 conversion for the Remington 700 ML. But now I'm happy to announce that we now offer a similar sealed breech 209 system for the Ruger 77/50! Much like the Remington 700 ML and 700ADL, Ruger sold a muzzle loader that looks a lot like the Ruger 77/44: the Ruger 77/50. According to the Ruger website, it was in production from 1997-2004. Judging by serial number data no where near as many were made as the 700ML. The Ruger functioned very similar to the Remington, and even had a breech thread that allowed use of 700ML breech plugs. (Not that we nor the manufacturer are endorsing that. It's just so similar it's possible). Thus these rifles had many of the same problems as the Remington 700 ML: Blow-back, frequent misfires, and factory setups that didn't have 209 options. So when Ruger owners find the Badger Ridge Industries 209 kit for the Remington 700ML, they often contact us and ask if we can make a similar "seal up the breech, BlackHorn209 compatible, finger simple prime de-prime system" for the Ruger 77/50. Now, I'm proud to say "YES WE CAN!" In order to develop and prove out our sealed breech 77/50 209 conversion a few 77/50's were purchased and converted by Fred and myself. Having a couple of centerfire Ruger 77 MKII's that I've hunted with for years, in many ways the 77/50 didn't feel like a totally new rifle to me, even though it was a 'totally new' rifle to me. And while on the surface it works similar to the Remington, and the breech plug threads of both are essentially identical, the 77/50 is a very different rifle to convert. As the rifle came from the factory, or even when modified with a Canadian 209 system, the warning about "Hot Gases Exit Nipple Area" excerpted from the 77/50 manual rings true and must be heeded. Hot gasses and pieces of primers/caps being blown back and around the nipple and the associated fouling are some time referred to as "blow by". However I find it seems more accurate to call it "Blow Back". The later version of the 77/50 used a protrusion on the bolt itself to try and direct the blow back to the side of the rifle. And while it does accomplish this, it also directs blow-back into the bolt. The bolt has a vent in the bolt body that directs the blow back that enters it down and into the stock! So as delivered from Ruger, blow back gets in the bolt, and is even directed down and into the inner recesses of the rifle! This complicates cleaning and over the long term reduces the reliability of the system. So compared to the Remington we had to modify the Ruger's bolt much more to get a 209 system that seals the breech and is more reliable. The main reason to switch to our system is not only to use 209 primers, but to seal up the breech area and essentially eliminate all of the blow back issues. 209 primers are hotter and more reliable source of ignition. Using them to seal blow back into the breech plug vastly simplifies cleaning and makes the rifle safer and more reliable. Our conversion seals out the elements and allows one to shoot Blackhorn 209 powder. Which in my opinion is the best black powder substitute available. The Canadian 209 system and the original cap system are not Blackhorn 209 compatible, and they allow blow back into all those nooks and crannies. Remember, blow-back not only can injure a shooter or by stander, but it can burn the optics mounted above the breech, project corrosive fouling throughout the bolt and action, and wear out a mainspring prematurely. Even worse, the Ruger 77/50 is known to have an additional deficiency: Blow back launches the firing pin rearward and occasionally shears the trigger's sear! Our conversion for the Ruger 77/50 fixes all of these woes by sealing the blow back into the breech plug with the 209 primer! The conversion process requires the bolt to be completely stripped, our new firing pin to be installed, the extended shroud to be cut off, and the nose of the bolt dressed. Then the 209 nose is timed to align it for loading and unloading, pressed on, and firing pin protrusion set. So once complete there really isn't any going back. But once the converted rifle is shot, I'm sure no one will ever want to go back to the leaky original set up! Our Ruger 77/50 conversion is through its first rounds of testing but is still in what the DoD would call LRIP (low rate initial production). I'm not comfortable sending this one out for just anyone to install, and for now, will only offer it as a full conversion service. Or in other words, I'm not willing to sell this one as a kit; you will have to pay me to install it. The Ruger conversion uses a very similiar breech plug to the one used in our Remington system: If you are interested in making your rifle work the way you always wanted it to, and Blackhorn 209 compatible, you can purchase Ruger 77/50 conversion as a service (very similar to our Remington 700ML conversion service). Mail us your bolt, we'll convert, and send it back with the breech plug, vent liner, and other accessories. The details are all in the listing for this service!

We also can ship an entire new 209 converted bolt to you if you want to keep the original leaky system, or are missing a bolt etc. That is more expensive than converting an existing bolt. We do not recommend this unless you hunt out west where leaky non 209 systems are required for special hunts, but on others you can use our sealed breech 209 system. And as always feel free to use the Contact form to send me your info. I'll call or email back promptly.

20 Comments

Riley

9/25/2017 00:37:44

What's the cost of a full assembly for the Ruger m77?

Reply

Robert Harne

10/21/2017 13:21:11

What is the price for this conversion

Reply

Jim Brown

11/14/2017 11:11:42

How easy is it to remove spent primers? Are there issues with primer misalignment with the 209 recess in the breech plug? I am considering this conversion for my Ruger.

Reply

Typically you pull the spent primer with your fingers. No misalignment issues. The nose feeds the primer into the breech plug. It seals by getting a .003 to .005" crush. So when extracting the primer it comes right out of the breech plug.

Reply

Jim Brown

12/7/2017 08:45:49

Tom, I am curious. What does the vent liner screw do?

Short answer: The vent liner is a removable flash hole... so that when the flash hole (small hole down the middle of it) enlarges, you just replace the vent liner.

Reply

B Qunn

1/6/2018 21:17:11

I'm very interested for two Ruger 77-50s that I have (and some Remington ML700s as well). I understand that you do the work on the Ruger bolt(s) but will send the complete works to fix the Remingtons. Here's my question: if you aim for a crush on the primers as indicated between the bolt face and the breech plug face, and I install the breech plug, how can you ensure that, or put differently, how will I know I've achieved the correct 'crush', neither too much nor too little? I suppose the breech plug could be marked and backed out a quarter or one-third turn or so if too much gap, but how about too little? Re the latter, will that be apparent with too forced a closing of the bolt, but what would that be like or feel like? Would there be any telltale marks on the primer in either instance (after firing), either too much gap or too little? And finally, you imply (or indeed state) that the breech plug will, over time and use, open up, such that more than .036 it's time for a fresh one; in other forums, Chuck Hawks' for instance, he talks of carbonization in the breech plug hole for black powder rifles generally and drilling out the carbon occasionally, without any numbers for reference, but nonetheless. These two views seem inconsistent, can you enlighten? Thanks, looking forward to hearing from you.

Reply

Mr. Quin,

Reply

B Qunn

1/8/2018 01:14:43

Hello again, thanks for the answers, some more questions. First, the "209 nose" piece which, once the overhang deflecting piece on the original bolt is cut off, is pressed on, 1) is this piece stainless steel?, 2) how deep into the bolt is it pressed?, 3) how do you set the firing pin protrusion? Do you start out with an overlong pin and install it into the various bolts you get and then cut any excess off? Also, I see from your setup that if there is backward movement from the primer firing, it bucks against the new bolt face (inside the 209 nose) much more than against the protruding firing pin, which is more like a usual firing pin in size unlike the original which is basically a big flat cylinder end-on, and thus would greatly reduce the reported 'sear shearing' over time (unlike the Canadian kit which, although it replaces the original firing pin cylinder with another with a bump on it, to make the primer fire, it's still a relatively big cylinder end-on, an only held in place by the mainspring, so any rearward thrust could push the firing pin back and may over time deform the sear (maybe)); I like yours. FWIW the hole in the Ruger bolt is as I see it a gas escape hole, just like the same in the bolt action Mauser/Springfield/Winchester 70, etc. It may have the unintended effect if there is blowback of fouling the works under the bolt or on the trigger mechanism, but its main purpose is safe gas management I would assume; having said that, not having any blowback at all is best, still leaving the hole for unfortunate extraordinary rearward escapes of gas like from punctured primers. I do find it odd that, once the bolt is locked, the gas hole points horizontally to the left into a channel which would allow the gas to go down; I would have preferred it pointed straight down from the bolt , but perhaps that would have exposed the hole even more to day-to-day dirt, etc., directly into the bolt where the firing pin and spring reside, so not good. But I'm glad it's there, the Remington 700ML doesn't have one.

Reply

Mr. Qunn,

Reply

Oh, and I'm 100% sure that the sears in the Ruger 77/50 were stressed and broken by the original design driving the firing pin rearward into them. The Canadian mod worsened this, and the Bager Ridge Conversion completely eliminates blow back driving the firing pin rear-ward.

Reply

B Qunn

1/8/2018 01:38:19

Further to my point on handling rearward escaping gas, obviously the main outlet would be the substantial hole (if that's the right word, it's basically the right side length of the action between the 'chamber' (if you will) and the rear bridge of the action) to the right of the bolt where the action dips down to facilitate primer loading (in a cartridge rifle, to load the cartridges); the escape hole in the Ruger bolt is just to handle whatever gas enters the bolt, if any, since most will blow up and out to the right which, as far as I can see, cannot be stopped or managed on inline muzzleloaders (on cartridge rifles, the bolt locks up about 1" deep inside a big hole in the end of the action or barrel and so if gas escapes rearwards there into that chamber from a ruptured case or punctured primer, to manage it, they usually have an escape hole drilled into the right side of this overhang, sometimes both sides; they also have escape holes in the bolt for whatever gas gets inside the bolt). One additional question: could you comment on whether the likelihood of escaping gas with an inline muzzleloader with a breechplug is significantly more or less than with a cartridge rifle; I assume much less, as with a cartridge rifle you can get either a punctured primer (here too) but you can also get a ruptured case side or bottom, whereas here you have the breech plug between you or the action and the powder burn, and surely a threaded breechplug is many times stronger than brass cartridge cases, so you only really have to worry about a punctured primer, and your system limits that, as well as reducing the likelihood of over-time sear shear. Agree?

Reply

There is a lot to this question.

Reply

B QUINN

2/1/2019 16:09:02

Thanks for all these comprehensive answers to my comprehensive questions (yes, I show up once a year bidden or not). Re your last paragraph, what are "witness marks"? Are these the markings you make on your ramrod to show when you've seated a bullet, etc.? Or something else? Thanks, and I still have the Rugers and the Rems, and hope soon to proceed with the upgrade kits. Life has a way of getting in the way, as you know. Witness marks are marks on ram rods. When the ram rod is placed all the way into the barrel and abuts the breech plug: if the witness mark aligns with the end of the muzzle it will indicate if the rifle is charged or not (depending on where you put the witness mark). I personally make marks that indicate where the barrel aligns when empty. Any other alignment means the rifle is loaded.

Bill Walden

12/1/2018 19:08:24

Hey Tom, I'm very interested in your ruger 77/50 conversion.

Reply

Our Ruger kit costs $245.95 installed for US customers (Canadian customers will have to pay an additional $10.00 Canadian shipping fee). To have me convert the rifle, all I'll need is your rifle’s bolt. From when your bolt hits my hands to when it’s back in the mail is typically under 2 weeks. These prices include shipping from me to you.

Reply

Leave a Reply. |

Welcome to the Badger's Den!

|

|

|

Written by:Tom, purveyor of fine products. |

Archives

March 2024

August 2023

June 2023

March 2022

December 2021

September 2021

February 2021

January 2021

September 2020

April 2020

January 2020

October 2019

September 2019

May 2019

January 2019

November 2018

July 2018

May 2018

April 2018

February 2018

January 2018

November 2017

October 2017

August 2017

July 2017

April 2017

February 2017

January 2017

November 2016

October 2016

September 2016

August 2016

July 2016

June 2016

May 2016

December 2015

November 2015

October 2015

September 2015

August 2015

May 2015

April 2015

Categories

All

AR Stuff

Blackhorn 209

Customer Feedback

Hunting Gear & Accessories

Maintenance

Organization

Remington 700 ML/MLS

Ruger 77/50

Savage Muzzleloader

Troubleshooting

RSS Feed

RSS Feed