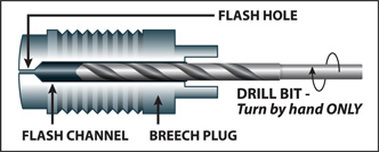

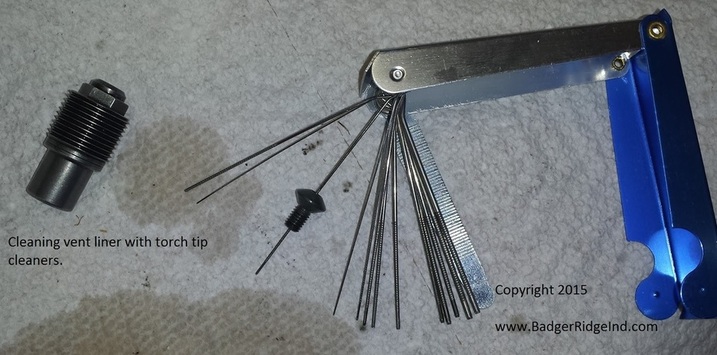

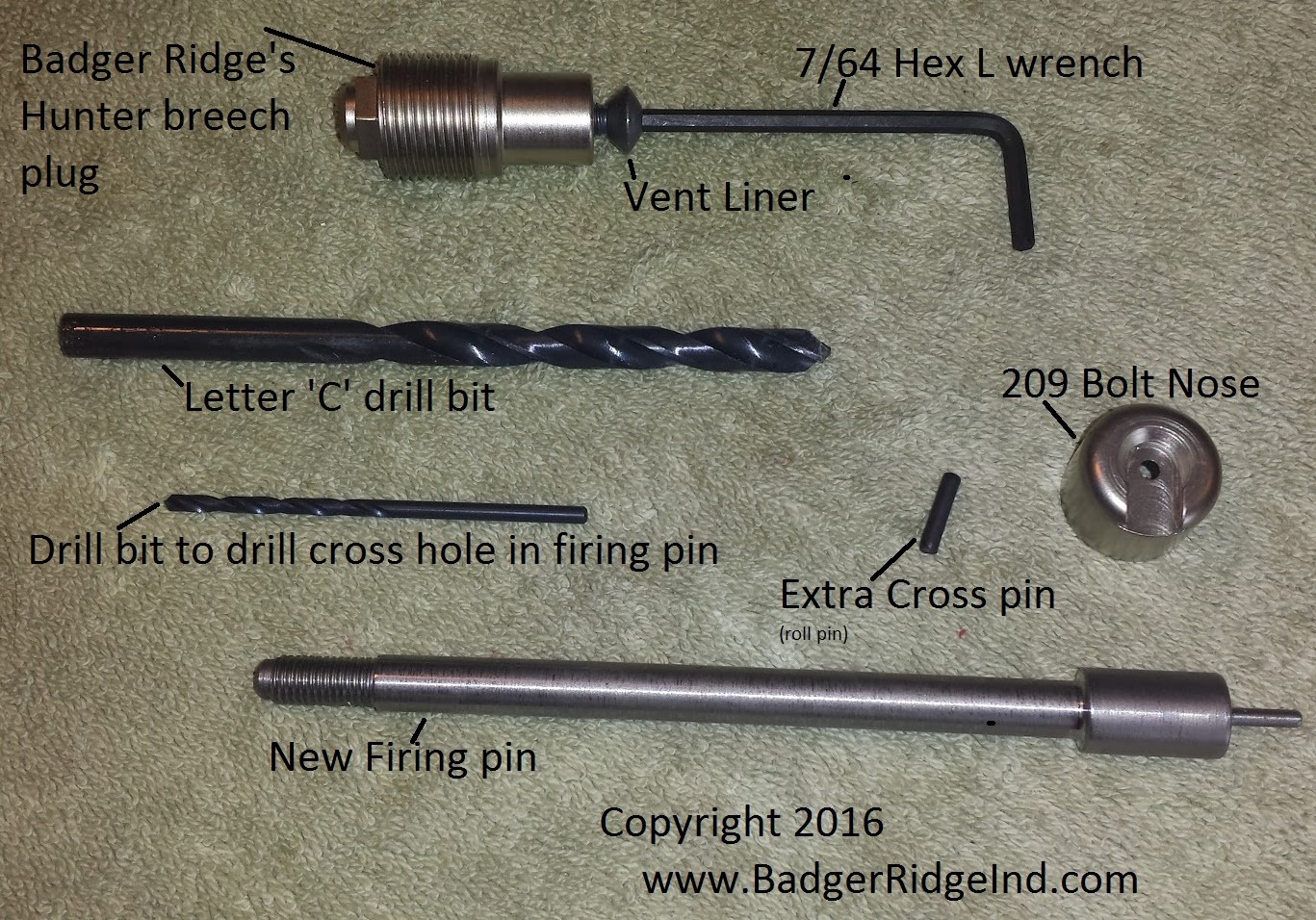

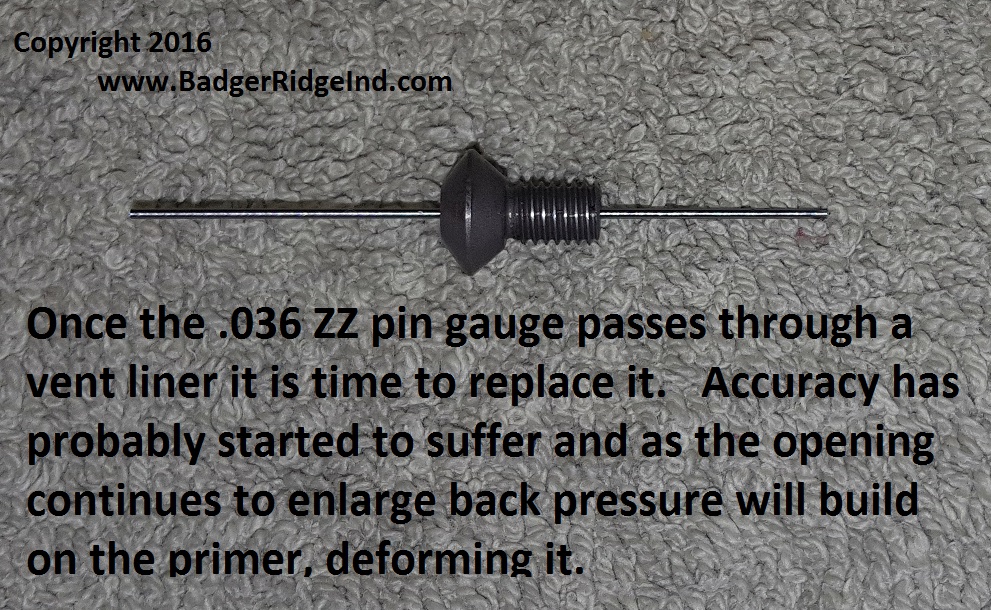

The Remington 700 ML 209 shot shell conversion kit we sell is very different from the original rifle's system, or any other 209 systems available for the 700 MLS. Our system uses a bolt nose that holds and feeds the primers into our unique breech plug. The action of the bolt swages the 209 primer into the breech plug; sealing it up, and essentially eliminating blow back. Thus it requires a little different maintenance than the original system. Most of that is due to our breech plug being of a different design: It uses a vent liner. So people only familiar with the old system, do have a new component and some learning to do. But it's not hard; it is simple breech plug maintenance. The instructions that come with the kit explain this, and it gets into more depth in our Frequently Asked Questions (FAQ). There is a lot of good reading in our FAQ but I wanted to emphasize it again here. Excerpted from the instructions that come with the kit: Breech plug maintenance: After firing 209 primers, burnt priming compound will coat the flash chamber & the flash hole of the Vent Liner. To clean: remove the breech plug & ream the flash chamber gently with a just under size drill bit (7/32). Use torch tip cleaners to clean the vent liner. Scrub & remove all fouling with the appropriate solvents, & place anti seize on all breech plug/vent liner threads before using the breech plug. Eventually the vent liner will wear out; it should be replaced when it’s interior has opened to .036” or accuracy will suffer. Always use a vent liner in the breech plug, or you may see excessive/unsafe pressures at the primer!!!  Generic breech plug from Blackhorn209.com Generic breech plug from Blackhorn209.com None of this is new to anyone who has owned or used many of the newer designs that use 209's to seal up the breech. Here is an generic breech plug maintenance image from Blackhorn209.com:  The main difference between our breech plug and the generic one above it that ours uses a vent liner to form the flash hole. This is because each shot erodes away part of the flash hole, and if the flash hole was machined into the breech plug eventually the entire breech plug would require replacement. It's much better to only have to purchase an inexpensive common vent liner, over replacing an entire breech plug.  So that leaves the question: "When is it time to replace the vent liner?" The simple answer is when its interior has opened up to .036. Vent liners start at about .030 and open up oh so little with each shot. We sell .036 ZZ gauge pins to help you determine when its time to replace them. Alternatively when you use torch tip cleaners to clean the vent liner, you can measure the largest one that will pass through. When its .036 or larger, replace the vent liner. Or in other words, if the .036 ZZ pin gage passes through, replace the vent liner. If you don't replace the vent liner when it opens to .036 you can expect a drop in accuracy. If you keep shooting you'll continue to open it up, accuracy will degrade, and back pressure will start deforming primers. You can read more about this in the FAQ (Frequently Asked Questions)

1 Comment

|

Welcome to the Badger's Den!

|

|

|

Written by:Tom, purveyor of fine products. |

Archives

March 2024

August 2023

June 2023

March 2022

December 2021

September 2021

February 2021

January 2021

September 2020

April 2020

January 2020

October 2019

September 2019

May 2019

January 2019

November 2018

July 2018

May 2018

April 2018

February 2018

January 2018

November 2017

October 2017

August 2017

July 2017

April 2017

February 2017

January 2017

November 2016

October 2016

September 2016

August 2016

July 2016

June 2016

May 2016

December 2015

November 2015

October 2015

September 2015

August 2015

May 2015

April 2015

Categories

All

AR Stuff

Blackhorn 209

Customer Feedback

Hunting Gear & Accessories

Maintenance

Organization

Remington 700 ML/MLS

Ruger 77/50

Savage Muzzleloader

Troubleshooting

RSS Feed

RSS Feed